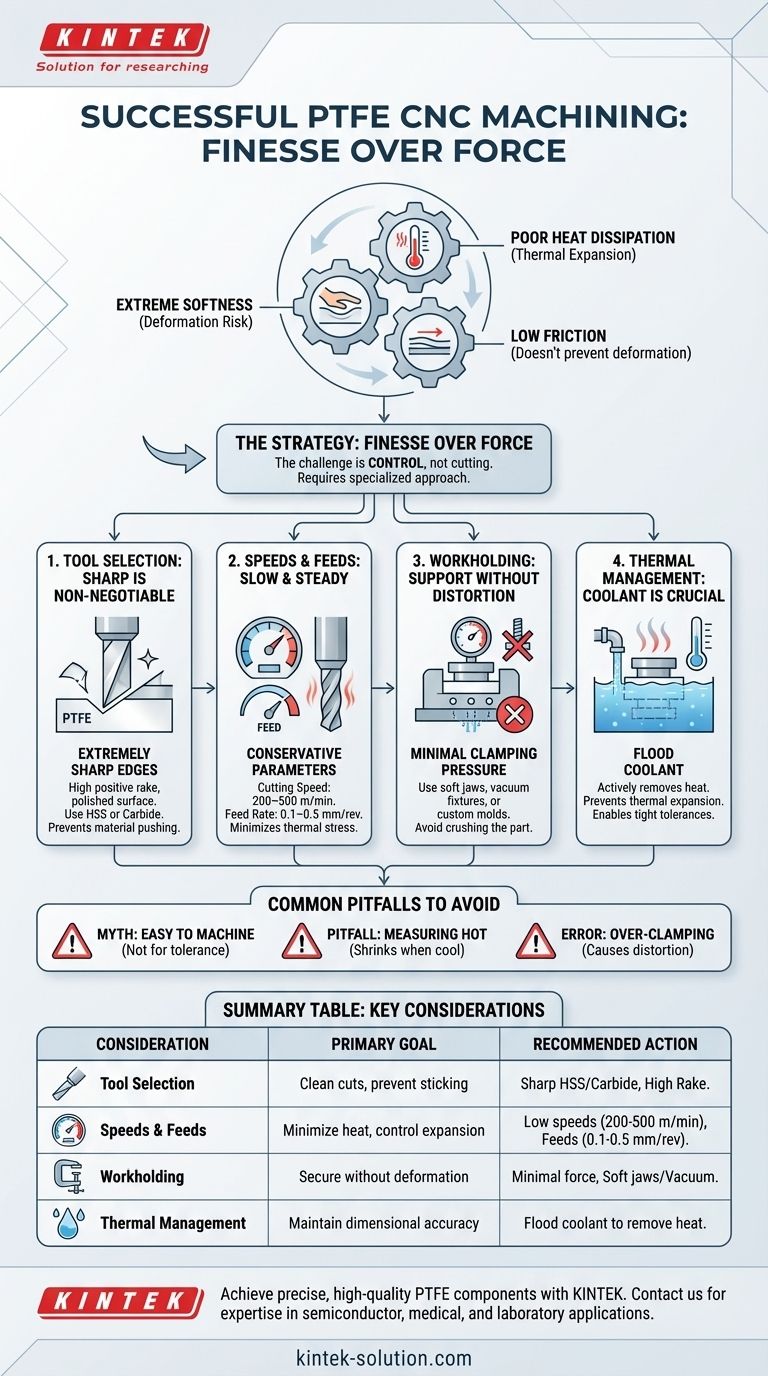

To successfully machine PTFE, you must adopt a strategy that accounts for its unique properties: extreme softness, poor heat dissipation, and high thermal expansion. This requires using exceptionally sharp tools, applying minimal clamping force to prevent deformation, and using low cutting speeds and feed rates to manage heat buildup and maintain dimensional accuracy.

The central challenge of machining PTFE is not cutting the material, but controlling it. Unlike metals, which are rigid, PTFE will readily deform under pressure and expand with heat, making a "finesse over force" approach essential for achieving tight tolerances and a quality finish.

Why PTFE Demands a Specialized Approach

Polytetrafluoroethylene (PTFE), often known by the brand name Teflon, is prized for its low friction, chemical inertness, and high-temperature resistance. However, the very properties that make it valuable in application also make it challenging on the CNC machine.

The Challenge of Softness and Low Rigidity

PTFE is an extremely soft material. This means it offers little resistance to a cutting tool, but it also means it can be easily compressed, stretched, or deformed.

Applying excessive clamping pressure or using a dull tool will not cut the material cleanly but will instead push it out of the way, leading to dimensional inaccuracies and warping.

The Paradox of Heat Buildup

While PTFE can withstand extreme temperatures in its final application, it is a poor thermal conductor. It does not dissipate heat well during machining.

This trapped heat causes the material to expand significantly—a property known as a high coefficient of thermal expansion. This expansion can ruin tight tolerances, as a part machined "hot" will shrink and go out of spec as it cools.

The Impact of Low Friction

PTFE's exceptionally low coefficient of friction is a key benefit, reducing wear in finished parts. During machining, this property helps reduce friction on the tool itself.

However, it does not compensate for the material's tendency to deform under pressure or expand with heat, which remain the primary challenges.

The Pillars of Precision PTFE Machining

A successful strategy for machining PTFE is built on precise control over tooling, machine parameters, and workholding.

Tool Selection: Sharpness is Non-Negotiable

The single most important factor is tool sharpness. A sharp cutting edge slices the material cleanly rather than pushing it.

Use High-Speed Steel (HSS) or carbide tools with a very high positive rake and a polished, smooth surface to prevent material from sticking to the tool.

Speeds and Feeds: Slow and Steady

To prevent heat buildup, you must use conservative cutting parameters. High speeds generate friction and heat, leading to thermal expansion.

Aim for optimal cutting speeds between 200–500 m/min and feed rates of 0.1–0.5 mm/rev. These lower parameters minimize thermal stress on the workpiece.

Workholding: Support Without Distortion

Properly securing PTFE is critical. Standard vise clamping is often too aggressive and will distort the part.

Use fixtures that provide broad support with minimal clamping pressure. Specialized soft jaws, vacuum fixtures, or custom-molded fixtures are highly effective at holding the part securely without crushing it.

Thermal Management: The Role of Coolants

Using a flood coolant serves two purposes: it lubricates the cut and, more importantly, it actively carries heat away from the workpiece.

This thermal management is crucial for preventing the thermal expansion that destroys dimensional accuracy, allowing you to hold much tighter tolerances.

Common Pitfalls to Avoid

Understanding the theory is one thing; avoiding common mistakes is another. Awareness of these pitfalls is key to preventing scrapped parts and wasted time.

The Myth of "Easy to Machine"

PTFE is often described as having high machinability. This simply means it is easy to cut and causes very little tool wear.

It does not mean it is easy to hold tight tolerances. The challenge lies in controlling the material's physical response to the machining process.

Chasing Tolerances Without Accounting for Expansion

A common mistake is measuring the part while it is still warm from the cutting process. The measurements will be inaccurate, as the part will shrink once it cools to ambient temperature.

Always allow the workpiece to normalize its temperature before taking final measurements for critical dimensions.

Over-clamping: The Primary Cause of Distortion

The natural instinct is to clamp a workpiece tightly. With PTFE, this is the fastest way to ruin a part before the first cut is even made.

Always begin with the absolute minimum clamping force required to hold the part and only increase it if necessary. The goal is to secure, not deform.

Making the Right Choice for Your Goal

Your specific objective will determine which aspect of the process you need to prioritize.

- If your primary focus is dimensional accuracy: Prioritize thermal management above all else by using ample coolant and conservative speeds to prevent thermal expansion.

- If your primary focus is a superior surface finish: Emphasize using extremely sharp, polished tools with a high rake angle and taking light, consistent finishing passes.

- If you are machining complex or thin-walled parts: Focus on robust, non-distorting workholding, as these features are the most susceptible to deformation under pressure.

By respecting PTFE's unique properties instead of fighting them, you can transform its machining challenges into predictable and successful outcomes.

Summary Table:

| Key Consideration | Primary Goal | Recommended Action |

|---|---|---|

| Tool Selection | Clean cuts, prevent material sticking | Use extremely sharp HSS/carbide tools with a high positive rake. |

| Speeds & Feeds | Minimize heat buildup, control expansion | Use low speeds (200-500 m/min) and feed rates (0.1-0.5 mm/rev). |

| Workholding | Secure part without deformation | Apply minimal clamping force; use soft jaws or vacuum fixtures. |

| Thermal Management | Maintain dimensional accuracy | Use flood coolant to actively remove heat from the workpiece. |

Achieve precise, high-quality PTFE components with KINTEK.

Machining PTFE for semiconductor, medical, or laboratory applications requires specialized expertise to overcome its unique challenges. KINTEK excels in precision PTFE manufacturing, from custom prototypes to high-volume orders. We leverage our deep understanding of material properties to deliver parts that meet your tightest tolerances.

Let us put our expertise to work for you. Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs