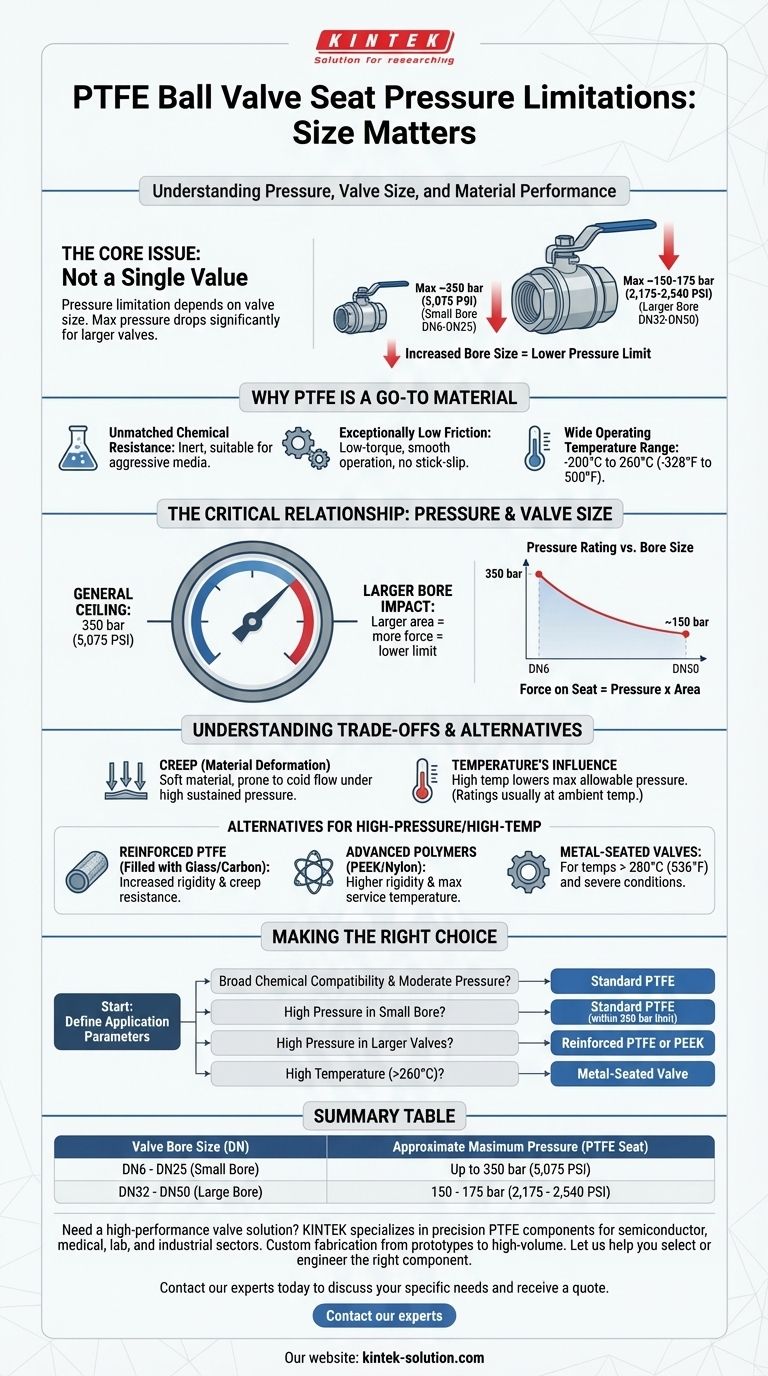

In short, the pressure limitation for a PTFE ball valve seat is not a single value but depends heavily on the valve's size. While PTFE is generally not recommended for pressures above 350 bar (approximately 5,075 PSI), this limit applies only to smaller bore valves. For larger valves, the maximum allowable pressure drops significantly.

The core issue isn't just the material's strength, but how pressure and valve size interact. As the valve's bore size increases, the force exerted on the seat material also increases, forcing a reduction in the maximum allowable system pressure.

Why PTFE is a Go-To Material for Valve Seats

Before examining its limitations, it's important to understand why Polytetrafluoroethylene (PTFE) is a default choice for many applications. Its unique combination of properties makes it exceptionally versatile.

Unmatched Chemical Resistance

PTFE is nearly inert, making it suitable for contact with a vast range of aggressive media. This is why it's so common for all media-wetted surfaces in a valve.

Exceptionally Low Friction

With one of the lowest coefficients of friction of any solid material, PTFE ensures low-torque, smooth operation. This prevents the "stick-slip" behavior common with other materials, allowing for reliable and easy quarter-turn actuation.

Wide Operating Temperature Range

PTFE performs reliably across an impressive thermal spectrum, typically from -200°C to 260°C (-328°F to 500°F). This range far exceeds the capabilities of most common elastomers and plastics, making it suitable for both cryogenic and high-temperature services.

The Critical Relationship: Pressure and Valve Size

The most common point of failure in selecting a PTFE seat is misunderstanding how pressure ratings change with the physical dimensions of the valve.

The General Pressure Ceiling

For most applications, the absolute maximum pressure you should consider for a standard PTFE seat is 350 bar (5,075 PSI). Exceeding this, even in ideal conditions, pushes the material beyond its reliable service limit.

How Bore Size Dictates the Limit

The pressure rating is inversely proportional to the valve size. The force on the seat is pressure multiplied by the area it acts upon. A larger ball creates a larger surface area, concentrating more force onto the seat material.

- For small bore sizes (DN6-DN25), the 350 bar limit is generally achievable.

- For larger bore sizes (DN32-DN50), the pressure limit drops dramatically to around 150-175 bar (2,175-2,540 PSI).

Understanding the Trade-offs

While its benefits are clear, PTFE is not without its limitations. These trade-offs become critical in demanding, high-performance applications.

Material Deformation (Creep)

PTFE is a relatively soft material, which helps it create an excellent seal. However, under high sustained pressure, it can be prone to cold flow, or "creep," where the material slowly deforms, potentially compromising the seal over time.

Temperature's Influence on Pressure

Pressure ratings for valve seats are almost always specified at ambient temperature. As the service temperature increases toward PTFE's upper limit of 260°C (500°F), its structural integrity decreases, which in turn lowers its maximum allowable pressure.

When to Look Beyond Standard PTFE

If your application involves a combination of high pressure (especially in larger valves) and elevated temperatures, standard PTFE is likely not the right choice. You must consider more robust materials.

Alternatives for High-Pressure and High-Temperature Service

When standard PTFE cannot meet operational demands, several alternatives are available, each designed to overcome specific limitations.

Reinforced PTFE

By adding fillers like glass fiber or carbon, powder-filled PTFE gains rigidity and improved resistance to creep. This can increase its pressure-handling capabilities without sacrificing chemical resistance.

Advanced Polymers

For conditions exceeding PTFE's limits, materials like Polyether-etherketone (PEEK) or special grades of Nylon offer higher rigidity and a greater maximum service temperature, making them suitable for more extreme pressures.

Metal-Seated Valves

When service temperatures are expected to exceed 280°C (536°F), polymers are no longer viable. In these cases, metal-seated ball valves are the required solution, offering durability in severe service conditions.

Making the Right Choice for Your Application

Selecting the correct seat material requires a clear understanding of your system's operational parameters.

- If your primary focus is broad chemical compatibility at moderate pressures: Standard PTFE is an excellent and cost-effective choice.

- If your primary focus is high pressure in small-bore instrumentation valves: Standard PTFE is often sufficient, provided you stay within the 350 bar limit.

- If your primary focus is high pressure in process lines with larger valves: You must specify a reinforced material like filled PTFE or an advanced polymer like PEEK.

- If your primary focus is high temperature (above 260°C): A metal-seated valve is the only reliable option.

Ultimately, choosing the right valve seat is about aligning the material's specific capabilities with the precise demands of your application.

Summary Table:

| Valve Bore Size (DN) | Approximate Maximum Pressure (PTFE Seat) |

|---|---|

| DN6 - DN25 (Small Bore) | Up to 350 bar (5,075 PSI) |

| DN32 - DN50 (Large Bore) | 150 - 175 bar (2,175 - 2,540 PSI) |

Need a high-performance valve solution for demanding conditions?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals and custom valve seats, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution perfectly matched to your application's pressure, temperature, and chemical resistance requirements.

Let us help you select or engineer the right component for your system.

Contact our experts today to discuss your specific needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs