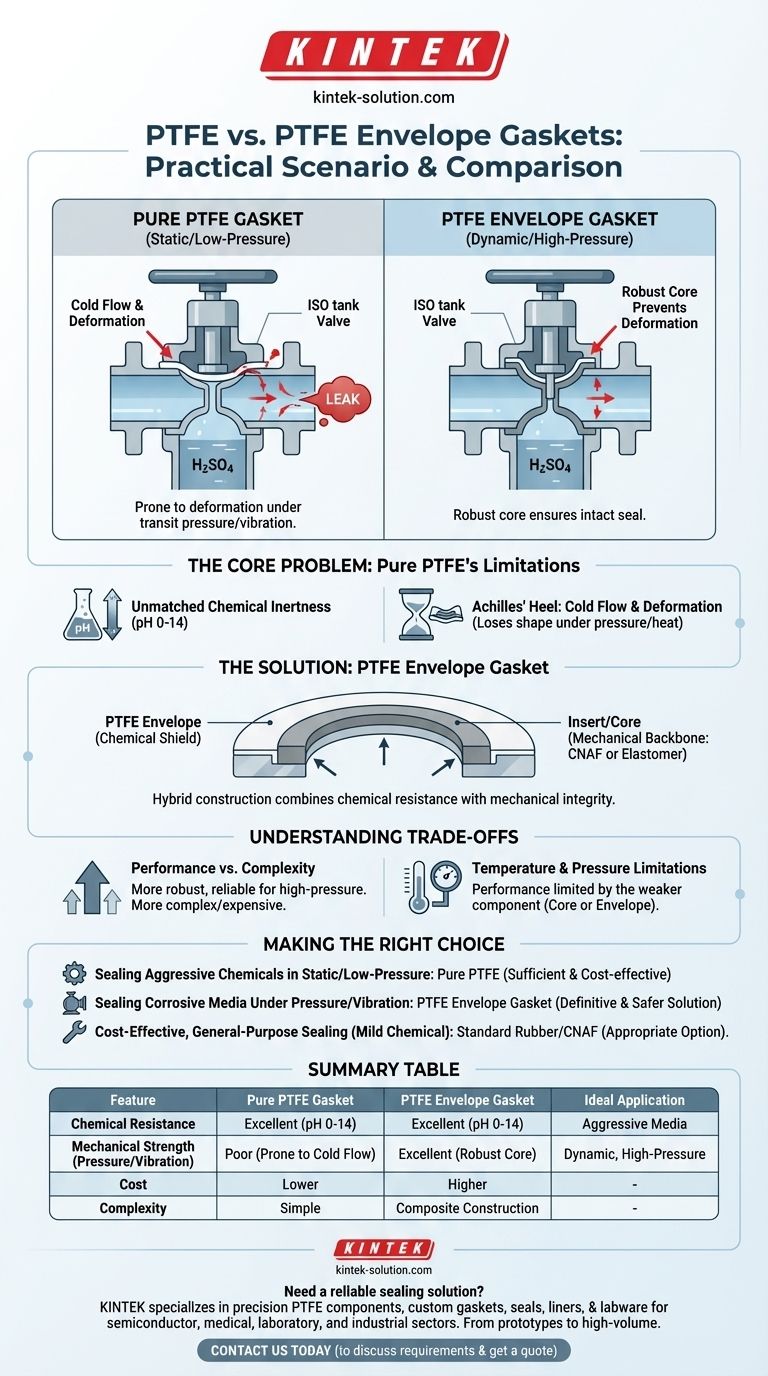

In a practical scenario like sealing an ISO tank transporting concentrated sulfuric acid, a pure PTFE gasket provides the necessary chemical resistance but is prone to deforming under the pressure and vibration of transit, which can lead to a critical leak. A PTFE envelope gasket is the superior choice here, as its robust inner core prevents deformation, ensuring the seal remains intact while the outer PTFE layer handles the chemical corrosion.

The fundamental difference lies in mechanical stability. While pure PTFE offers unmatched chemical resistance, it can fail under pressure. A PTFE envelope gasket solves this by adding a strong core material, combining PTFE's chemical inertness with the mechanical integrity needed for demanding industrial applications.

The Core Problem: Pure PTFE's Limitations

To understand why the envelope gasket exists, you must first understand the primary weakness of using PTFE on its own as a sealing material.

Unmatched Chemical Inertness

Polytetrafluoroethylene, or PTFE, is one of the most chemically resistant materials available. It can seal aggressive acids and caustic media across the entire pH range (0-14), making it invaluable in corrosive environments.

The Achilles' Heel: Cold Flow and Deformation

The major drawback of pure PTFE is its susceptibility to "cold flow," or creep. Under mechanical pressure and temperature fluctuations, the material slowly deforms and loses its original shape.

This deformation compromises the gasket's ability to maintain a tight seal. In a dynamic environment with vibration or pressure changes, a pure PTFE gasket can loosen over time, resulting in a dangerous leak.

The Solution: The PTFE Envelope Gasket

The PTFE envelope gasket was engineered specifically to overcome the mechanical failures of pure PTFE while retaining its signature chemical resistance.

A Hybrid Construction

This is a composite gasket. It consists of a thin outer "envelope" made of pure PTFE that encases a different, more resilient insert or core material.

The PTFE envelope is the only part that touches the corrosive media, providing a complete chemical shield.

The Role of the Core Material

The core is the gasket's mechanical backbone. It is typically made from materials like compressed non-asbestos fiber (CNAF) or various elastomers (rubber).

This core provides the strength, resilience, and resistance to pressure that pure PTFE lacks. It pushes back against the flange surfaces, maintaining a consistent, reliable seal even under stress.

Understanding the Trade-offs

Choosing between these gaskets requires acknowledging that the enhanced performance of an envelope gasket comes with specific considerations.

Performance vs. Complexity

The composite nature of the envelope gasket makes it a more robust and reliable sealing solution for high-pressure or dynamic systems.

However, this multi-material construction also makes it more complex to manufacture and typically more expensive than a simple, pure PTFE gasket.

Temperature and Pressure Limitations

While a PTFE envelope gasket dramatically improves on the mechanical weaknesses of pure PTFE, its ultimate performance is still limited by its components.

The core material has its own temperature and pressure ratings. The gasket's overall operational limits are determined by the weaker of its two components—the PTFE envelope or the inner core.

Making the Right Choice for Your Application

Your decision should be driven by a clear understanding of the mechanical and chemical demands of your specific environment.

- If your primary focus is sealing aggressive chemicals in a static, low-pressure system: A pure PTFE gasket may be a sufficient and cost-effective choice.

- If your primary focus is sealing corrosive media under pressure, vibration, or thermal cycling: The PTFE envelope gasket is the definitive and safer solution.

- If your primary focus is cost-effective, general-purpose sealing with only mild chemical exposure: A standard rubber or CNAF gasket may be a more appropriate option.

Ultimately, select the gasket that provides the necessary chemical resistance while ensuring the mechanical integrity required to maintain a safe and reliable seal.

Summary Table:

| Feature | Pure PTFE Gasket | PTFE Envelope Gasket |

|---|---|---|

| Chemical Resistance | Excellent (pH 0-14) | Excellent (pH 0-14) |

| Mechanical Strength (Pressure/Vibration) | Poor (Prone to Cold Flow) | Excellent (Robust Core) |

| Ideal Application | Static, Low-Pressure Systems | Dynamic, High-Pressure Systems |

| Cost | Lower | Higher |

| Complexity | Simple | Composite Construction |

Need a reliable sealing solution for corrosive or high-pressure environments?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom gaskets, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a cost-effective pure PTFE gasket for static applications or a robust PTFE envelope gasket for demanding conditions, our team can provide the perfect custom fabrication—from prototypes to high-volume orders.

Let us help you ensure safety and prevent costly downtime. Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications