At their core, Polytetrafluoroethylene (PTFE) oil scraper rings are specialized seals installed on the pistons of air compressors. Their primary function is to meticulously control lubrication by scraping excess oil from the cylinder walls on the piston's downstroke. This action prevents oil from contaminating the compressed air while simultaneously leaving a microscopic film of oil to ensure moving parts remain lubricated.

The essential role of a PTFE oil scraper ring is a balancing act: it must ensure air purity by preventing oil carryover into the compression chamber, while also guaranteeing the compressor's longevity by maintaining just enough lubrication to minimize friction and wear.

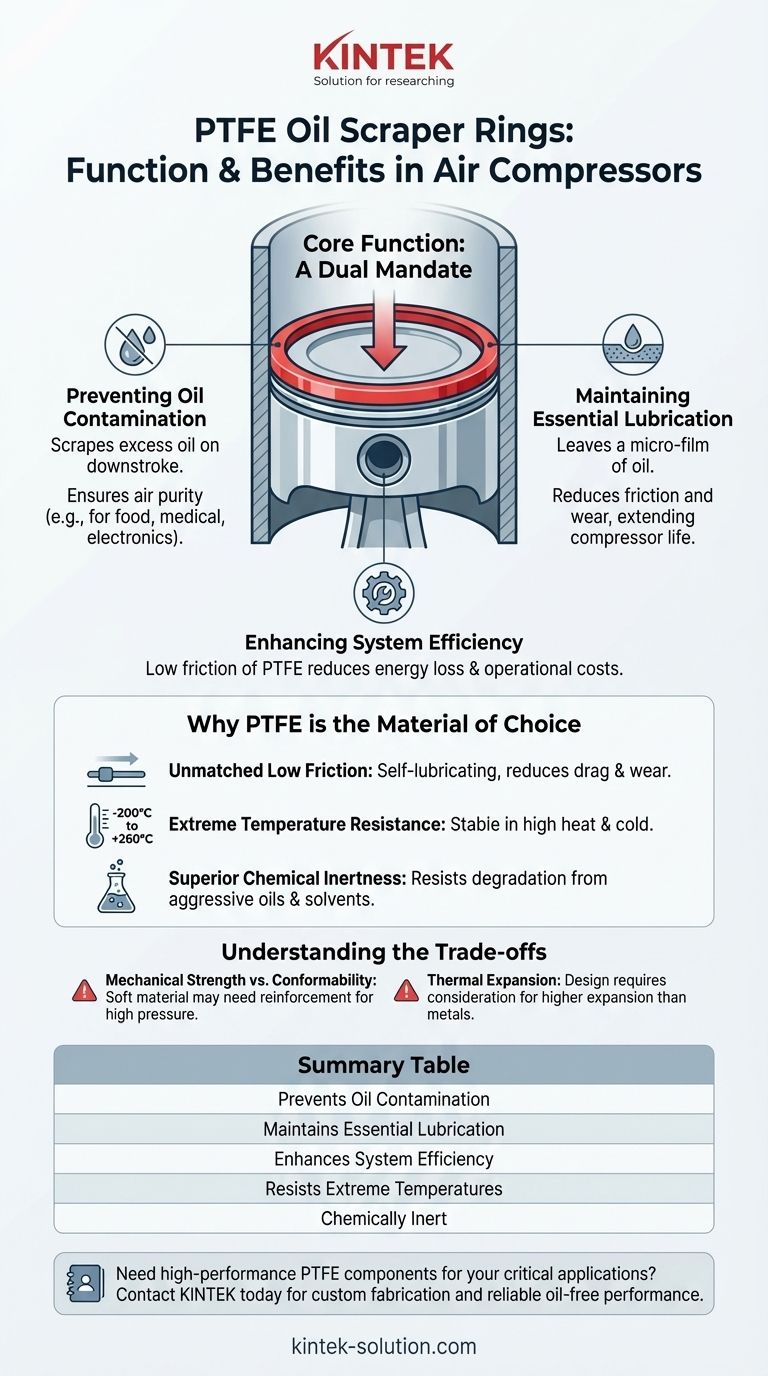

The Core Function: A Dual Mandate

The scraper ring is not just a simple barrier; it is an active component engineered to perform two critical, opposing tasks simultaneously. Its success defines the compressor's efficiency and the quality of the air it delivers.

Preventing Oil Contamination

The most crucial function is to prevent lubricating oil from the crankcase from entering the compression chamber. This is often called "oil carryover."

By scraping the vast majority of oil off the cylinder wall, the ring ensures the final compressed air is free from oil aerosols. This is paramount in applications like food processing, medical systems, and electronics manufacturing, where oil-free air is a strict requirement.

Maintaining Essential Lubrication

While removing excess oil, the ring's design is precisely calibrated to leave a very thin, uniform film of oil on the cylinder wall.

This micro-film is vital. It reduces the friction between the piston rings and the cylinder, preventing the "stick-slip" effect, minimizing wear, and dissipating heat. Without this film, the compressor would suffer from increased energy consumption and premature failure.

Enhancing System Efficiency

The inherently low friction of PTFE significantly reduces the energy lost to overcoming the resistance between the piston and the cylinder.

This translates directly to lower operational costs and improved overall compressor efficiency. The smooth, non-adhesive surface ensures consistent performance over millions of cycles.

Why PTFE is the Material of Choice

The unique challenges of this role—constant motion, high temperatures, and chemical exposure—demand a material with a specific set of properties. PTFE, a high-performance fluoropolymer, is exceptionally well-suited for this task.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is its most significant advantage, allowing it to glide effortlessly along the cylinder wall.

This characteristic is what enables the ring to function effectively even with a minimal lubricating film, reducing drag and a major source of wear.

Extreme Temperature Resistance

Air compressors generate significant heat. PTFE maintains its integrity and properties across an exceptionally wide thermal range, typically from –200°C to +260°C (–328°F to +500°F).

This stability ensures the ring does not become brittle at low temperatures or soften and degrade at the peak operating temperatures of the compressor, providing consistent sealing performance.

Superior Chemical Inertness

Compressor oils, additives, and potential environmental contaminants can be chemically aggressive. PTFE is virtually inert, meaning it resists degradation from almost all industrial chemicals and solvents.

This chemical resistance prevents the ring from swelling, hardening, or breaking down over time, guaranteeing a longer service life and system reliability.

Understanding the Trade-offs

While PTFE is a superior material, no engineering choice is without its considerations. Understanding these trade-offs is key to proper application and design.

Mechanical Strength vs. Conformability

PTFE is a relatively soft and formable material. This high elongation allows it to conform perfectly to the cylinder wall for an excellent seal and makes installation easier.

However, its lower mechanical strength compared to metal rings means it may be less suitable for extremely high-pressure differentials without reinforcement or specialized design. Often, PTFE is blended with fillers (like carbon, glass, or bronze) to enhance its strength and wear resistance for more demanding jobs.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. Engineers must account for this in the design of the piston groove.

The groove must provide enough clearance to allow the ring to expand as it heats up without binding, while still maintaining a proper seal when the compressor is cold. Improper design can lead to either leaks or catastrophic failure.

Where PTFE Scraper Rings are Essential

The decision to use PTFE rings is driven by the demands of the application. They are considered indispensable in a wide range of compressor systems.

- If your primary focus is air purity: PTFE rings are the standard for oil-free compressors used in medical, food and beverage, and electronics industries.

- If your primary focus is efficiency and long-term reliability: The low friction and high durability of PTFE reduce energy consumption and extend maintenance intervals in demanding industrial plants.

- If your primary focus is operating in harsh environments: PTFE's chemical and thermal resistance makes it the ideal choice for compressors in chemical plants or high-pressure petrochemical applications.

Ultimately, selecting the right ring material is a foundational decision that directly impacts the performance, efficiency, and longevity of the entire compressor system.

Summary Table:

| Function | Benefit |

|---|---|

| Prevents Oil Contamination | Ensures clean, oil-free air for sensitive applications (medical, food, electronics). |

| Maintains Essential Lubrication | Reduces friction and wear, extending compressor lifespan. |

| Enhances System Efficiency | Low-friction PTFE reduces energy consumption and operational costs. |

| Resists Extreme Temperatures | Stable performance from -200°C to +260°C. |

| Chemically Inert | Withstands aggressive oils and solvents for long-term reliability. |

Need high-performance PTFE components for your critical applications?

KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require standard parts or custom fabrication—from prototypes to high-volume orders—we deliver the reliability and oil-free performance your systems demand.

Contact KINTEK today to discuss your specific requirements and ensure your compressors operate at peak efficiency and purity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are PTFE fasteners used in applications requiring electrical insulation? Ensure Reliable, Non-Conductive Performance

- Why does the spring PTFE sealing ring maintain effective sealing across its working pressure range? Discover the Engineering Secret

- What are some specific uses of PTFE in chemical handling? Enhance Safety and Reliability in Your Process

- Why are PTFE-free bushings considered environmentally friendly? Reduce PFAS Risk & Enhance Sustainability

- What are the future trends for PTFE sheets in industrial innovation? From Commodity to Custom-Engineered Solutions

- How do Teflon washers compare to phosphor bronze washers in terms of wear? Choose the Right Washer for Your Application

- What advantages does PTFE's low coefficient of friction provide in bellows applications? Achieve Long-Lasting, Maintenance-Free Performance

- What are the main applications of PTFE lined ball valves? Control Corrosive & High-Purity Fluids Safely