In bellows applications, PTFE's low coefficient of friction is a critical advantage because it allows the component to endure millions of compression and extension cycles without suffering material degradation. This inherent slipperiness directly translates to superior durability, a more reliable seal, and significantly reduced maintenance over the lifespan of the equipment.

The core advantage is not just reduced friction, but the elimination of wear-related failures. By acting as its own lubricant, PTFE ensures bellows maintain their structural integrity and sealing capability in demanding, repetitive-motion environments, ultimately lowering the total cost of ownership.

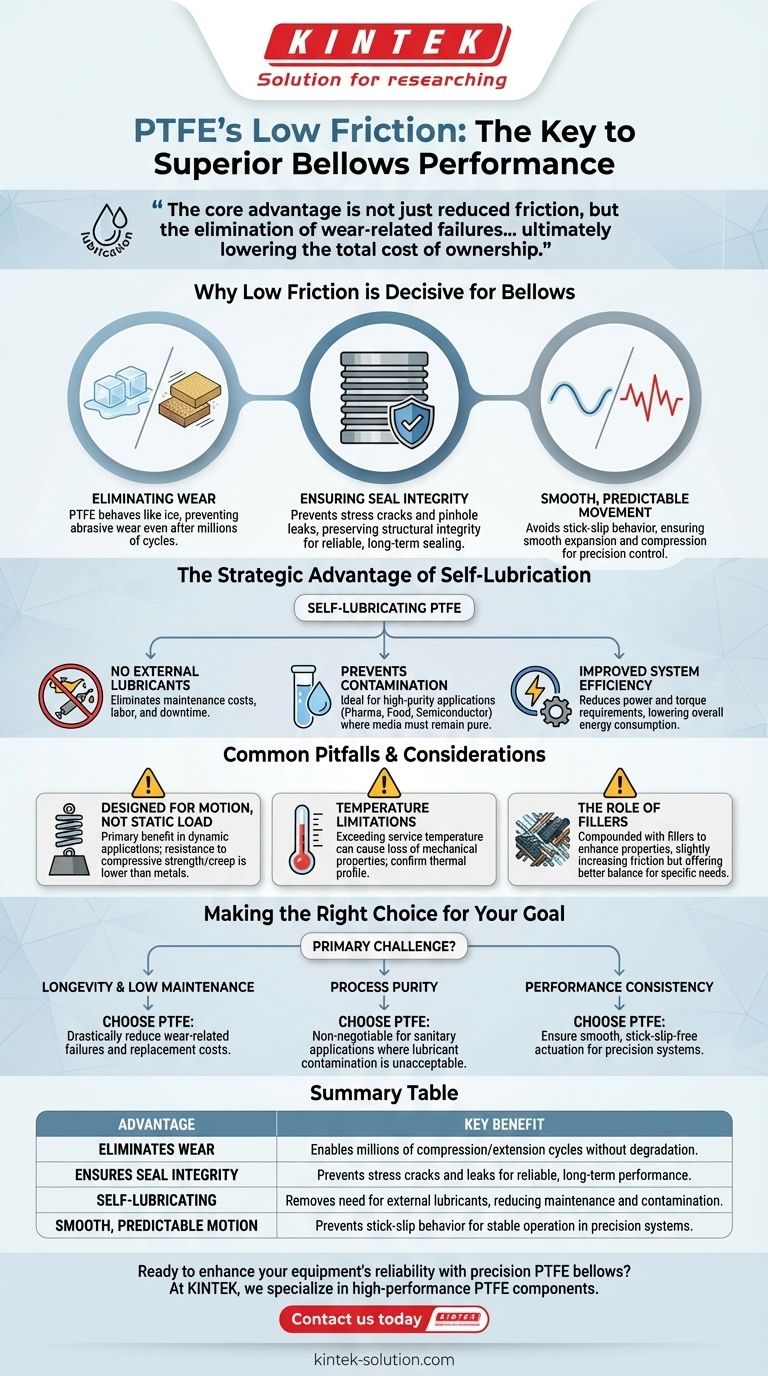

Why Low Friction is a Decisive Factor for Bellows

Bellows are dynamic components, constantly moving to accommodate thermal expansion, vibration, or misalignment. The material's ability to handle this movement without self-destructing is paramount.

Eliminating Wear from Repetitive Cycles

A bellow's primary function involves its walls folding and sliding against themselves. For most materials, this repeated contact would be like rubbing two pieces of sandpaper together, causing abrasion, thinning, and eventual failure.

PTFE, with the lowest coefficient of friction of any known solid, behaves more like two ice cubes sliding past one another. This self-lubricating property means there is virtually no abrasive wear, even after millions of cycles.

Ensuring Seal Integrity and Preventing Leaks

The most common failure mode for a bellow is a stress crack or pinhole leak caused by material fatigue and wear. By preventing the underlying cause of wear, PTFE's low friction directly preserves the structural integrity of the bellow walls.

This ensures a reliable, long-term seal, which is critical in applications handling corrosive chemicals or requiring vacuum-tight performance.

Achieving Smooth, Predictable Movement

Materials with higher friction can exhibit stick-slip behavior, where they resist initial movement before suddenly releasing. This creates jerky, unpredictable motion and places undue stress on the entire system.

PTFE's consistently low friction ensures the bellows compress and expand smoothly and predictably in response to pressure or mechanical changes. This is vital for the stability of precision instruments and control systems.

The Strategic Advantage of Self-Lubrication

The fact that PTFE is inherently slippery, requiring no external aid, unlocks several key operational benefits that go beyond simple durability.

Removing the Need for External Lubricants

In many mechanical systems, friction is managed with oils and greases. This is not a viable option for the internal surfaces of a bellow, making a self-lubricating material essential.

By choosing PTFE, you eliminate the cost, labor, and downtime associated with a lubrication maintenance schedule. The part simply works without intervention.

Preventing Process Contamination

PTFE’s self-lubricating nature makes it the default choice for high-purity applications. Industries like pharmaceuticals, food and beverage, and semiconductors cannot tolerate contamination from lubricants.

Because PTFE requires no oil or grease, it guarantees that the media flowing through the system remains pure and unadulterated.

Improving Overall System Efficiency

Friction is a force that resists motion and consumes energy. While the effect may be small for a single component, it adds up across a complex piece of equipment.

Systems using PTFE components require less power and torque to operate, contributing to greater overall energy efficiency and potentially allowing for the use of smaller, less costly motors or actuators.

Common Pitfalls and Considerations

While its low friction is a powerful advantage, it's important to understand the context in which PTFE excels.

Designed for Motion, Not Static Load

PTFE's primary benefit is in dynamic applications involving sliding or flexing. While strong, its resistance to deformation (compressive strength) and creep is lower than that of metals. For this reason, PTFE bellows are often designed with external reinforcement for high-pressure applications.

Temperature Limitations

Standard PTFE performs exceptionally well across a wide range of temperatures, but it has upper limits. Exceeding its service temperature can cause it to lose its mechanical properties, so confirming the application's thermal profile is a critical step.

The Role of Fillers

To enhance properties like compressive strength and wear resistance for even more demanding scenarios, PTFE is often compounded with fillers like glass, carbon, or bronze. While this can slightly increase the coefficient of friction, the resulting composite material offers a superior balance of properties for a specific challenge.

Making the Right Choice for Your Goal

The decision to use PTFE bellows should be based on the primary challenge you are trying to solve.

- If your primary focus is longevity and low maintenance: Choose PTFE to drastically reduce wear-related failures and eliminate the costs associated with component replacement and lubrication.

- If your primary focus is process purity: PTFE is non-negotiable for sanitary, food-grade, or semiconductor applications where lubricant contamination is unacceptable.

- If your primary focus is performance consistency: Use PTFE to ensure smooth, stick-slip-free actuation, which is critical for precision control systems and delicate instrumentation.

Ultimately, leveraging PTFE's low friction is a strategic engineering decision that prioritizes long-term reliability and operational excellence.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Eliminates Wear | Enables millions of compression/extension cycles without degradation. |

| Ensures Seal Integrity | Prevents stress cracks and leaks for reliable, long-term performance. |

| Self-Lubricating | Removes need for external lubricants, reducing maintenance and contamination. |

| Smooth, Predictable Motion | Prevents stick-slip behavior for stable operation in precision systems. |

Ready to enhance your equipment's reliability with precision PTFE bellows?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver the durability, purity, and efficiency your applications demand.

Contact us today to discuss your specific requirements for prototypes or high-volume orders and discover the KINTEK difference in precision fabrication.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- In what applications is PTFE commonly used due to its chemical resistance? Essential for Chemical, Pharma, and Oil & Gas

- What is the advantage of PTFE's self-lubricating properties in shaft seals? Achieve Reliable, Maintenance-Free Performance

- What are the advantages of ceramic fillers over glass reinforcements? Superior Thermal & High-Frequency Performance

- How does PEEK compare to PTFE for ball valve seats? Choose the Right Material for Your Application

- What should be considered when bonding PTFE sheets? A Guide to Achieving a Reliable, Permanent Bond

- What are the media resistance properties of PTFE with fillers? Retains Chemical Inertness While Boosting Durability

- What medical applications benefit from extruded PTFE rods? Precision Components for Surgical & Diagnostic Devices

- What are the key advantages of PTFE lined pipes? Superior Corrosion Resistance & Cost-Effective Flow