In a direct comparison, Teflon washers cause significantly less wear to the metal surfaces they contact than phosphor bronze washers. Because Teflon is a soft polymer, it acts as a protective, low-friction barrier, preserving the steel of a knife blade or pivot. Phosphor bronze, being a metal alloy, is harder and can gradually wear away the steel surfaces it rotates against over time.

The choice between Teflon and phosphor bronze is not about which is universally "better," but about which component you prefer to be the sacrificial part. Teflon washers sacrifice themselves to protect the steel, while phosphor bronze washers provide rigidity at the cost of slowly wearing the blade and liners.

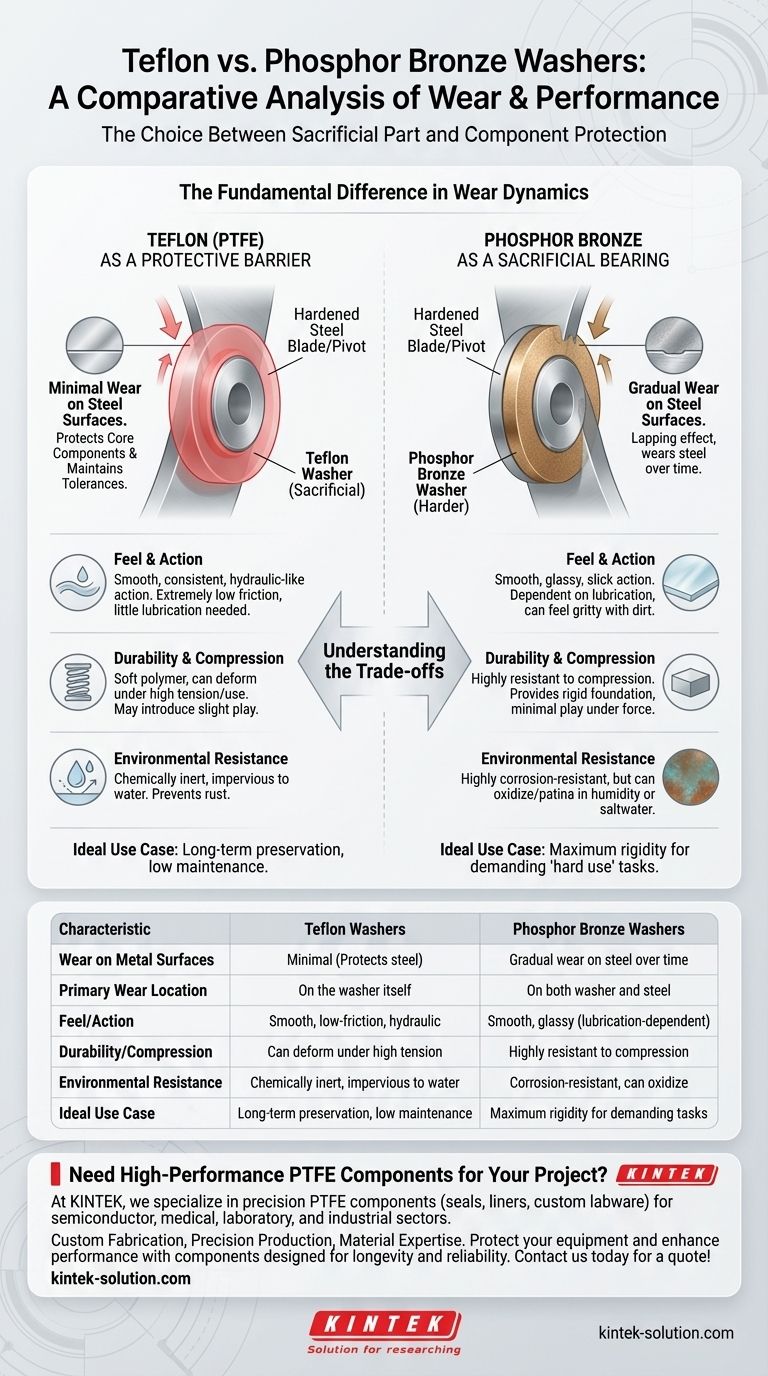

The Fundamental Difference in Wear Dynamics

To understand the long-term impact of these materials, you must see them not just as washers, but as two distinct types of bearing systems with different philosophies.

Teflon as a Protective Barrier

Teflon, or Polytetrafluoroethylene (PTFE), is a soft plastic. When placed in a pivot, any wear that occurs primarily happens to the Teflon washer itself.

This design preserves the more expensive and critical components of the assembly, such as a hardened steel blade tang or the frame liners. Because the steel parts are not abraded, the knife's original manufacturing tolerances are maintained for much longer.

Phosphor Bronze as a Sacrificial Bearing

Phosphor bronze is a hard, durable copper alloy. While it is softer than the hardened steel of a knife blade, it is still a metal rubbing against metal.

This contact, especially when contaminated with fine dust or debris, creates a lapping effect that slowly wears away the steel surfaces. The washer is acting as a durable, load-bearing surface that will eventually require replacement, but it also causes permanent wear to the knife itself.

Beyond Wear: Key Performance Characteristics

The material choice impacts more than just wear; it defines the feel, durability, and maintenance requirements of the entire mechanism.

Feel and Action

Teflon has an extremely low coefficient of friction. This results in a uniquely smooth, consistent, and almost "hydraulic" opening action that requires little to no lubrication.

Phosphor bronze also provides a very smooth action, often described as feeling "glassy" or "slick." However, its performance is more dependent on lubrication and can feel gritty if dirt enters the pivot.

Durability and Compression

This is the primary advantage of phosphor bronze. As a metal, it is highly resistant to compression and deformation. Under high pivot tension or lateral force on the blade, it provides a solid, rigid foundation with minimal blade play.

Teflon is soft and can be "squished" or deformed under excessive pivot tension or during heavy use. This deformation can introduce slight blade play over time that wasn't present from the factory.

Environmental Resistance

Teflon is chemically inert and impervious to water. This makes it an excellent choice for environments where corrosion is a concern, as it completely prevents rust from forming within the pivot.

Phosphor bronze is highly corrosion-resistant but can still oxidize or develop a patina over time, especially in humid or saltwater environments.

Understanding the Trade-offs

Neither material is perfect; the optimal choice depends entirely on your priority.

The Argument for Teflon: Investment Protection

If you view a tool like a folding knife as a long-term investment, Teflon is the superior choice for preservation. It ensures that after years of use, the blade and frame remain in their original condition. Any wear is isolated to the cheap, easily replaceable washers.

The Argument for Phosphor Bronze: Maximum Rigidity

If your primary need is maximum stability for "hard use" applications, phosphor bronze is often preferred. Its resistance to compression provides a more robust and solid-feeling pivot that can better withstand strong lateral forces without introducing play. This rigidity comes at the known cost of slowly consuming the steel.

Making the Right Choice for Your Goal

Ultimately, you must align your material choice with your intended use case.

- If your primary focus is long-term preservation and maintenance-free smoothness: Choose Teflon, as it protects the core components of your tool from wear.

- If your primary focus is maximum pivot rigidity for demanding tasks: Choose phosphor bronze, accepting that it is a wear item that also causes wear to the knife.

Choosing the right washer material is about deciding what you want to protect and what performance characteristic you value most.

Summary Table:

| Characteristic | Teflon Washers | Phosphor Bronze Washers |

|---|---|---|

| Wear on Metal Surfaces | Minimal (Protects steel) | Gradual wear on steel over time |

| Primary Wear Location | On the washer itself | On both the washer and the steel components |

| Feel/Action | Smooth, low-friction, hydraulic | Smooth, glassy (lubrication-dependent) |

| Durability/Compression | Can deform under high tension | Highly resistant to compression and deformation |

| Environmental Resistance | Chemically inert, impervious to water | Corrosion-resistant, but can oxidize |

| Ideal Use Case | Long-term preservation, low maintenance | Maximum rigidity for demanding tasks |

Need High-Performance PTFE Components for Your Project?

At KINTEK, we specialize in manufacturing precision PTFE components (including seals, liners, and custom labware) for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a protective Teflon washer or a custom-fabricated part, our expertise ensures superior performance and durability.

We offer:

- Custom Fabrication: From prototypes to high-volume orders.

- Precision Production: Ensuring exact tolerances for optimal performance.

- Material Expertise: Leveraging PTFE's unique properties for your specific application.

Protect your equipment and enhance performance with components designed for longevity and reliability.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications