At its core, Polytetrafluoroethylene (PTFE) is used for electrical insulation because it is one of the best commercially available materials for resisting the flow of electricity. Fasteners made from PTFE, such as screws, washers, and gaskets, leverage this inherent property to create a non-conductive barrier, effectively isolating sensitive components and preventing dangerous electrical shorts.

The true value of PTFE fasteners is not just their ability to insulate, but their capacity to maintain this critical electrical protection reliably across a wide range of temperatures and in chemically aggressive environments where other materials would fail.

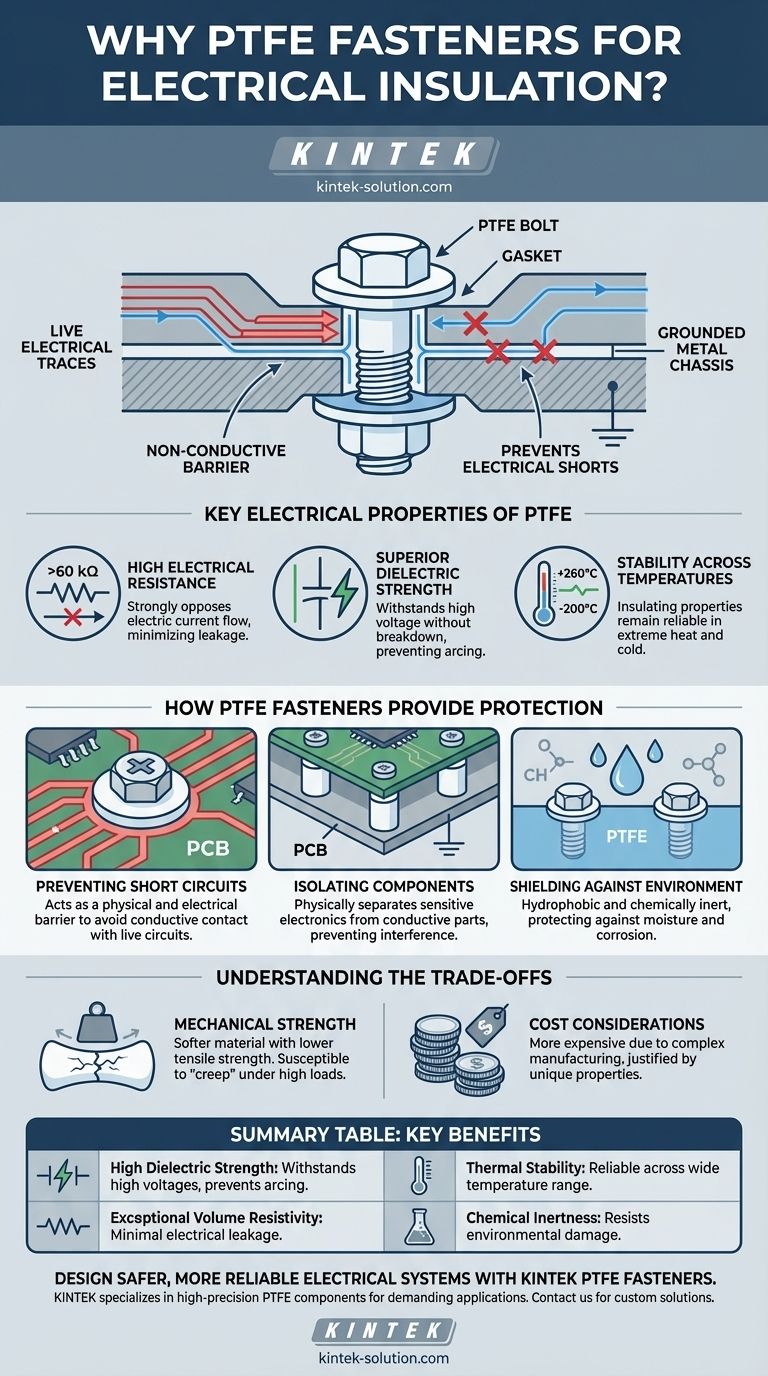

The Fundamental Electrical Properties of PTFE

The effectiveness of PTFE as an electrical insulator stems from its unique molecular structure, which results in several key electrical characteristics.

Exceptionally High Electrical Resistance

PTFE possesses an extremely high volume resistivity. This means it strongly opposes the flow of electric current through its material.

This property is fundamental to its role as an insulator, ensuring that electricity stays within its intended path rather than leaking to adjacent components.

Superior Dielectric Strength

Dielectric strength measures a material's ability to withstand a strong electric field without breaking down and becoming conductive.

PTFE has excellent dielectric strength, making it ideal for applications involving high voltages where preventing arcing or short-circuiting is a critical safety and operational requirement.

Stability Across Temperatures

Unlike many other polymers, PTFE's insulating properties remain remarkably stable across a very wide temperature range.

This consistency is crucial in electronic devices that generate heat, ensuring the fasteners continue to provide reliable insulation without degrading in performance.

How PTFE Fasteners Provide Electrical Protection

In practical applications, PTFE fasteners serve specific functions to ensure the safety and reliability of electrical and electronic systems.

Preventing Short Circuits

A common use for a PTFE washer or screw is to act as a physical and electrical barrier.

They can prevent a conductive metal screw from making contact with a live circuit trace on a printed circuit board (PCB), which would otherwise create a damaging short circuit.

Isolating Components and Assemblies

PTFE spacers and gaskets are widely used to physically separate electronic components or entire circuit boards from a metal chassis or other conductive parts.

This isolation is vital for protecting sensitive electronics and ensuring that stray currents do not interfere with the device's intended operation.

Shielding Against the Environment

PTFE is hydrophobic (repels water) and nearly chemically inert.

This means PTFE fasteners also help protect electrical connections from moisture, chemicals, and other contaminants that could otherwise corrode contacts or compromise insulation.

Understanding the Trade-offs

While its electrical properties are superior, PTFE is not the solution for every application. Its limitations must be considered for proper design.

Mechanical Strength

PTFE is a relatively soft material with lower tensile strength compared to metals or even other high-performance polymers.

It is not suitable for high-load, structural applications. Under sustained pressure, it can be susceptible to "creep," or slow deformation over time.

Cost Considerations

Due to the complex manufacturing process, PTFE fasteners are generally more expensive than their counterparts made from common materials like nylon or standard steel.

The cost is justified in applications where its unique combination of properties is a strict requirement.

Making the Right Choice for Your Goal

Selecting the correct fastener material requires balancing electrical needs with mechanical and environmental demands.

- If your primary focus is maximum electrical isolation in a demanding environment: PTFE is the superior choice for its high dielectric strength, chemical inertness, and thermal stability.

- If your application requires high mechanical strength with some insulation: Consider using a metal fastener in combination with a PTFE washer or sleeve to achieve both structural integrity and electrical isolation at the point of contact.

- If you need basic insulation for a low-voltage, cost-sensitive project: A polymer like Nylon may be a sufficient and more economical alternative, provided the chemical and temperature conditions are not extreme.

Ultimately, leveraging PTFE's properties correctly allows you to design safer, more durable, and more reliable electrical systems.

Summary Table:

| Key Property | Benefit for Electrical Insulation |

|---|---|

| High Dielectric Strength | Withstands high voltages without breakdown, preventing arcing and short circuits. |

| Exceptional Volume Resistivity | Strongly opposes current flow, ensuring minimal electrical leakage. |

| Thermal Stability | Maintains insulating properties across a wide temperature range (-200°C to +260°C). |

| Chemical Inertness | Resists moisture, chemicals, and contaminants that could compromise insulation. |

Design Safer, More Reliable Electrical Systems with KINTEK PTFE Fasteners

When your application demands uncompromising electrical insulation in harsh environments, the right material makes all the difference. KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, labware, and custom fasteners—for the semiconductor, medical, laboratory, and industrial sectors.

We understand that reliability is non-negotiable. Our PTFE fasteners provide the critical dielectric strength and chemical resistance needed to protect sensitive electronics, prevent short circuits, and ensure long-term performance.

Ready to enhance your design? Contact KINTEK today to discuss your project requirements. From prototypes to high-volume production, we deliver custom solutions that meet your exact specifications for performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability