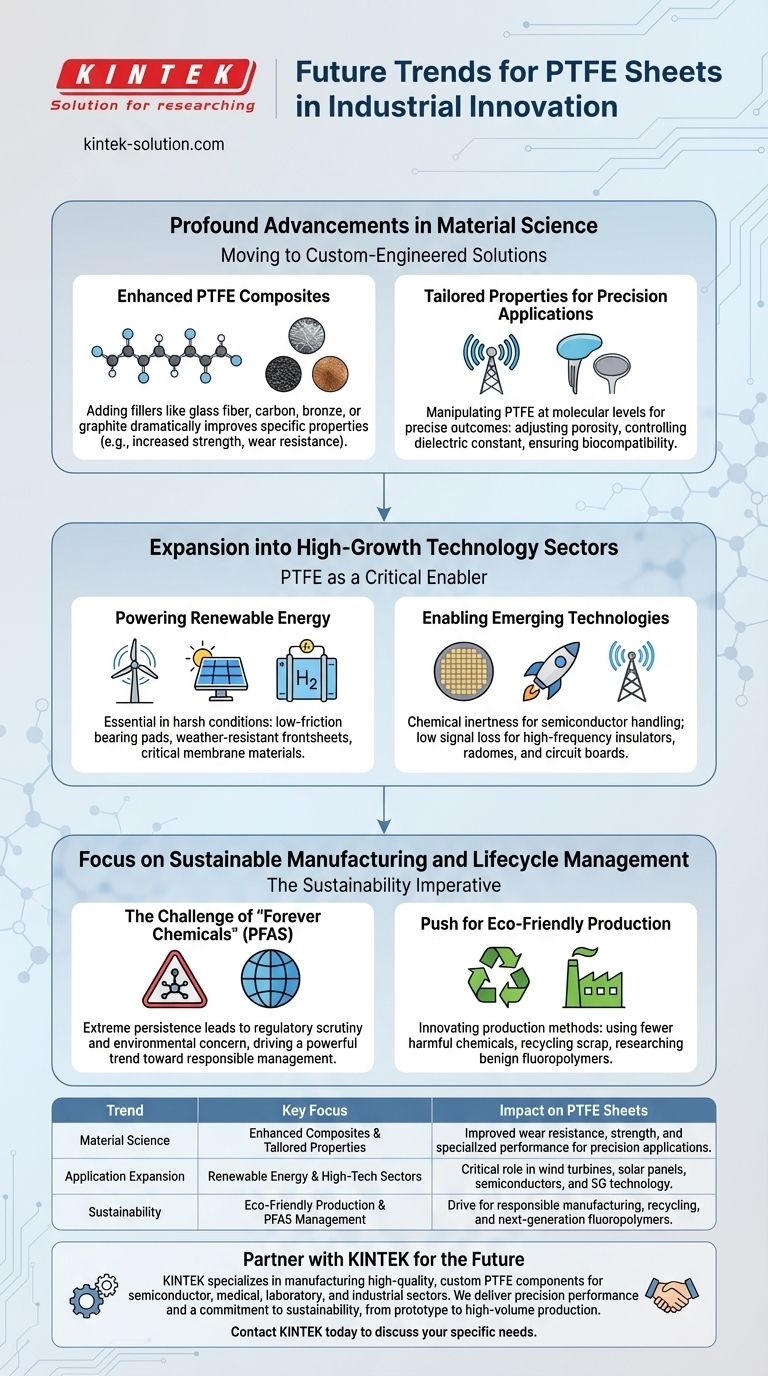

In the coming years, the future of Polytetrafluoroethylene (PTFE) sheets in industrial settings will be defined by three converging trends: profound advancements in material science, expansion into high-growth technology sectors, and an increasing focus on sustainable manufacturing and lifecycle management. These shifts are transforming PTFE from a reliable commodity into a highly specialized, engineered material.

The core trend is a move away from generic PTFE and toward custom-engineered solutions. The future isn't just about using PTFE in more places; it's about fundamentally redesigning the material itself to solve highly specific performance and environmental challenges.

The Evolution: From Commodity to Specialty Material

For decades, PTFE has been valued for a consistent set of properties: extreme chemical resistance, low friction, and high-temperature stability. The innovation trend is now focused on enhancing these properties and adding new ones to meet the demands of next-generation applications.

Enhanced PTFE Composites

Pure, or virgin, PTFE has limitations, such as low wear resistance and a tendency to deform under load (creep).

The most significant trend in material science is the development of enhanced PTFE composites. By adding fillers like glass fiber, carbon, bronze, or graphite, engineers can dramatically improve specific properties.

For example, adding carbon increases compressive strength and hardness, while glass fiber improves wear resistance. This allows for the creation of components that retain PTFE's core benefits while overcoming its inherent weaknesses.

Tailoring Properties for Precision Applications

The goal is no longer "one size fits all." Industries now require materials optimized for a single, critical function.

This trend involves manipulating PTFE at a molecular or structural level to achieve precise outcomes. This could mean adjusting porosity for advanced filtration systems, controlling dielectric constant for 5G communication antennas, or ensuring a specific level of biocompatibility for medical implants.

Expanding the Application Frontier

As PTFE becomes more adaptable, its use is expanding far beyond traditional seals and linings. It is becoming a critical enabler in some of the world's most innovative industries.

Powering Renewable Energy

The renewable energy sector operates in harsh conditions, requiring materials that offer extreme durability and efficiency.

PTFE sheets and components are now essential in wind turbines as low-friction bearing pads, in solar panels as protective, weather-resistant frontsheets, and in hydrogen fuel cells as critical membrane materials.

Enabling Emerging Technologies

The unique electrical and chemical properties of PTFE make it indispensable for high-tech manufacturing and communication.

In semiconductor manufacturing, its chemical inertness is vital for handling ultra-pure chemicals. In aerospace and 5G technology, its low signal loss at high frequencies makes it a superior material for insulators, radomes, and high-performance circuit boards.

Understanding the Trade-offs: The Sustainability Imperative

The remarkable stability of PTFE is both its greatest strength and its most significant challenge. This has placed sustainability at the forefront of future innovation.

The Challenge of "Forever Chemicals"

PTFE belongs to the family of per- and polyfluoroalkyl substances (PFAS), often called "forever chemicals" due to their extreme persistence in the environment.

Regulatory scrutiny and public concern over PFAS are driving a powerful trend toward responsible manufacturing and end-of-life management. This is the most critical headwind the industry faces.

The Push for Eco-Friendly Production

In response, leading manufacturers are innovating their production methods. This includes developing processes that use fewer harmful chemicals, recycling scrap material, and researching new fluoropolymers with a more benign environmental profile.

Choosing a supplier is no longer just about material specs; it's about vetting their environmental stewardship and commitment to sustainable practices.

How to Apply This to Your Project

Your approach to specifying PTFE must evolve with these trends. It is now less about selecting a material and more about defining a performance and sustainability target.

- If your primary focus is extreme mechanical performance: Investigate custom-filled PTFE composites to achieve the precise wear, load, or thermal properties your application demands.

- If your primary focus is high-tech electrical applications: Look to specialized PTFE grades engineered for a specific dielectric constant and low signal loss required by sectors like 5G and aerospace.

- If your primary focus is corporate responsibility and future-proofing: Prioritize suppliers who can provide transparent data on sustainable manufacturing and are actively investing in next-generation, environmentally conscious fluoropolymers.

Ultimately, leveraging the future of PTFE means treating it not as an off-the-shelf product, but as a platform for targeted innovation.

Summary Table:

| Trend | Key Focus | Impact on PTFE Sheets |

|---|---|---|

| Material Science | Enhanced Composites & Tailored Properties | Improved wear resistance, strength, and specialized performance for precision applications. |

| Application Expansion | Renewable Energy & High-Tech Sectors | Critical role in wind turbines, solar panels, semiconductors, and 5G technology. |

| Sustainability | Eco-Friendly Production & PFAS Management | Drive for responsible manufacturing, recycling, and next-generation fluoropolymers. |

Ready to leverage the future of PTFE for your project?

As these trends show, success now depends on partnering with a supplier who can deliver both precision performance and a commitment to sustainability. KINTEK specializes in manufacturing high-quality, custom PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We work with you from prototype to high-volume production to create the exact custom-engineered PTFE solution your application demands. Let's build the future, responsibly.

Contact KINTEK today to discuss your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is the conclusion about PTFE-coated O-rings? A Guide to Their Limited, Specific Use Cases

- How do the non-stick properties of PTFE oil seals contribute to their performance? Ensure Long-Term Reliability in Harsh Conditions

- What are the key properties of PTFE Bellows? Achieve Unmatched Chemical & Thermal Resilience

- What is the pH range for both PTFE and graphite packing? Selecting the Right Material for Extreme Conditions

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What are the performance characteristics of Teflon bearings? Superior Self-Lubricating Performance for Demanding Environments

- What are some industrial applications of PTFE coatings? Enhance Performance in Demanding Environments

- What are the combined characteristics of PTFE rubber products? The Ultimate Hybrid for Demanding Seals