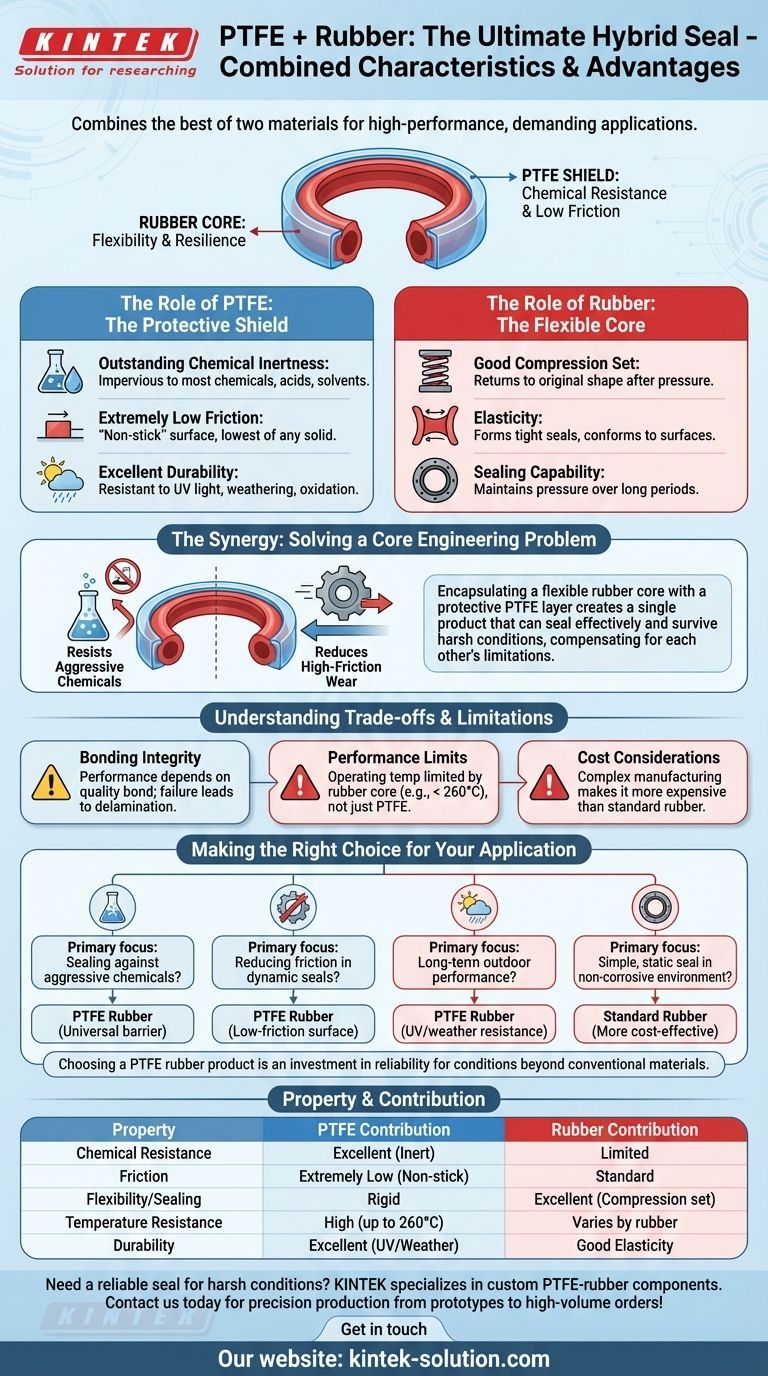

At their core, PTFE rubber products are hybrid materials designed to deliver the best properties of two distinct components. They combine the unparalleled chemical resistance and low-friction surface of PTFE with the flexibility and sealing capability of a rubber core, resulting in a high-performance material ideal for demanding applications.

The central advantage of a PTFE rubber product is its ability to create a resilient, flexible seal that is also protected from chemical attack, extreme temperatures, and friction by an inert PTFE layer.

How PTFE and Rubber Create a Superior Hybrid

To understand the combined characteristics, you must first appreciate the distinct role each material plays. The final product is not merely a mixture but a strategic combination where one material compensates for the other's limitations.

The Role of PTFE: The Protective Shield

PTFE (Polytetrafluoroethylene) acts as the external-facing armor for the product. Its contributions are primarily surface-level and environmental.

The molecular structure of PTFE, a linear polymer with high molecular weight, gives it a unique set of properties. It provides an extremely low coefficient of friction—the lowest of any known solid material.

This "non-stick" quality is paired with outstanding chemical inertness. PTFE is virtually impervious to attack from most chemicals, acids, and solvents.

Finally, PTFE is highly durable against weathering, showing excellent resistance to UV light, oxidation, and embrittlement, making it suitable for long-term outdoor use.

The Role of Rubber: The Flexible Core

While PTFE provides the robust shield, rubber provides the product's structural flexibility and resilience.

Rubber's primary contribution is its good compression set. This means it can be compressed to form a tight seal and will reliably return to its original shape once the pressure is released.

This elasticity is what allows the product to function effectively as a gasket or seal, conforming to surface imperfections and maintaining pressure over long periods.

The Synergy: Solving a Core Engineering Problem

Combining these materials solves a common failure point for seals and components. A standard rubber seal might offer flexibility but would quickly degrade when exposed to aggressive chemicals or high-friction movement.

Conversely, a solid PTFE component would be chemically resistant but too rigid to provide the reliable sealing pressure of an elastomer.

By encapsulating a flexible rubber core with a protective PTFE layer, you get a single product that can both seal effectively and survive harsh operating conditions.

Understanding the Trade-offs

While this hybrid approach offers significant advantages, it's essential to recognize the inherent trade-offs and potential limitations.

Manufacturing and Bonding Integrity

The performance of the final product is heavily dependent on the quality of the bond between the PTFE layer and the rubber core. Any failure in this bond can lead to delamination and a complete loss of function.

Performance Is Dictated by the Weakest Link

The combined product can only perform within the limits of its components. For example, while PTFE can withstand temperatures up to 260° C, the product's actual maximum operating temperature will be limited by the specific type of rubber used for the core.

Cost Considerations

Due to the more complex manufacturing process and the cost of raw materials (especially PTFE), these hybrid products are typically more expensive than standard, single-material rubber components. Their use is best justified in applications where standard materials would fail.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the demands of your specific environment.

- If your primary focus is sealing against aggressive chemicals: A PTFE rubber product is an excellent choice, as the PTFE layer provides a nearly universal chemical barrier.

- If your primary focus is reducing friction in a dynamic (moving) seal: The non-stick, low-friction surface of PTFE is a key advantage for improving efficiency and reducing wear.

- If your primary focus is long-term performance in an outdoor setting: The inherent UV and weather resistance of PTFE ensures longevity where other elastomers might degrade.

- If your primary focus is a simple, static seal in a non-corrosive environment: A standard, more cost-effective rubber product may be a more appropriate and economical choice.

Ultimately, choosing a PTFE rubber product is an investment in reliability for conditions that push beyond the limits of conventional materials.

Summary Table:

| Property | Contribution from PTFE | Contribution from Rubber |

|---|---|---|

| Chemical Resistance | Excellent, inert to most chemicals | Limited |

| Friction | Extremely low, non-stick surface | Standard |

| Flexibility/Sealing | Rigid | Excellent, good compression set |

| Temperature Resistance | High (up to 260°C) | Varies by rubber type |

| Durability | Excellent UV/weather resistance | Good elasticity |

Need a reliable seal for harsh conditions? KINTEK specializes in manufacturing high-performance PTFE components, including custom PTFE-rubber seals, liners, and labware. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a component that delivers unmatched chemical resistance, low friction, and long-term reliability for the semiconductor, medical, laboratory, and industrial sectors. Contact us today to discuss your specific application requirements! Get in touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs