In short, Teflon bearings are defined by an exceptional combination of performance characteristics. Their most notable attributes are an extremely low coefficient of friction, the ability to operate across a vast temperature range, and near-universal chemical resistance, making them a premier choice for specialized and demanding applications.

The core value of a Teflon bearing is not just one of its features, but its unique ability to deliver self-lubricating, maintenance-free performance in environments—from cryogenic freezers to corrosive chemical plants—where traditional lubricated metal bearings would quickly fail.

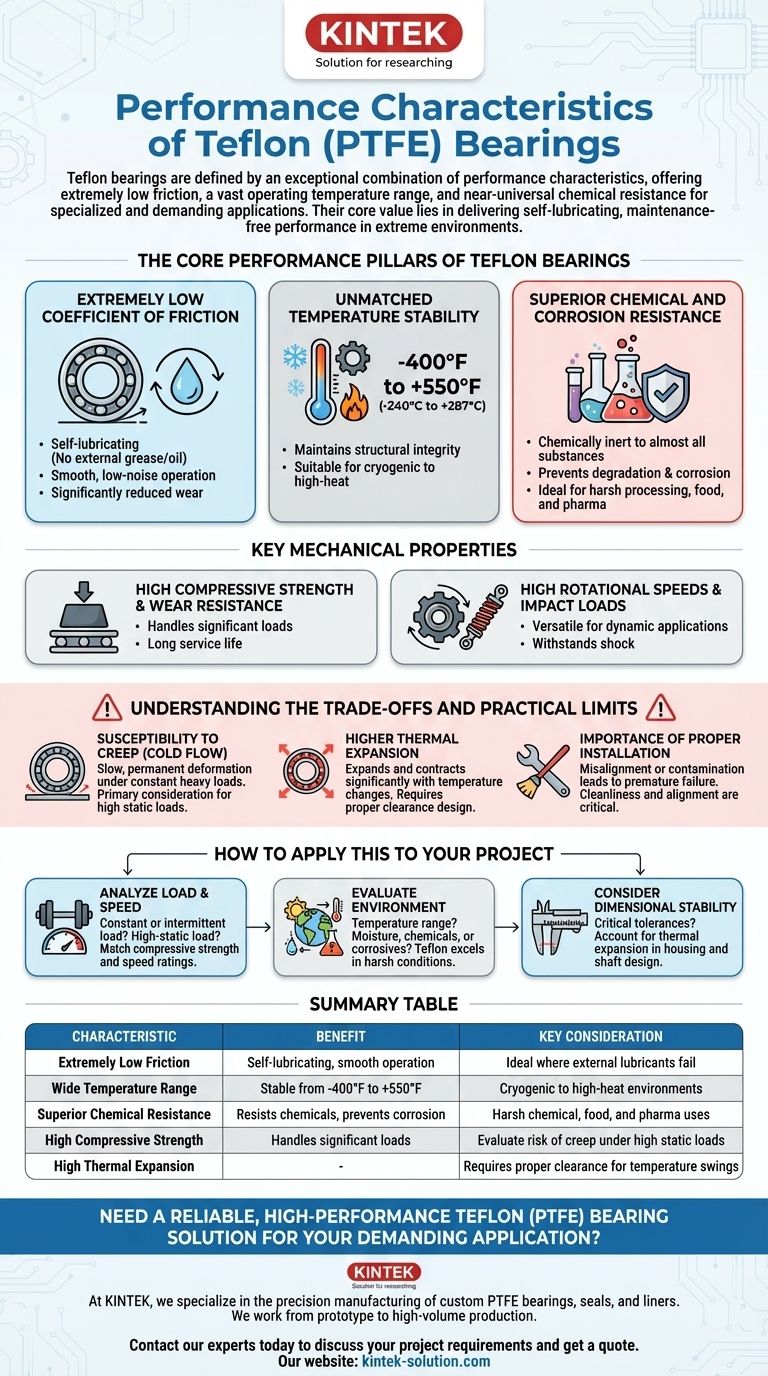

The Core Performance Pillars of Teflon Bearings

To properly evaluate if a Teflon bearing is right for your application, you must understand its primary operational strengths. These characteristics work in concert to create a robust and reliable component.

Extremely Low Coefficient of Friction

Teflon, or Polytetrafluoroethylene (PTFE), has one of the lowest coefficients of friction of any known solid material.

This inherent slipperiness means the bearings are self-lubricating. They do not require external grease or oil, which eliminates a common point of failure and maintenance.

The practical results are smooth, low-noise operation and significantly reduced wear over the component's lifespan.

Unmatched Temperature Stability

Teflon bearings exhibit remarkable performance in extreme thermal conditions.

They maintain their structural integrity and performance characteristics across a very wide temperature range, typically from -400°F to +550°F (-240°C to +287°C).

This makes them suitable for everything from cryogenic equipment to high-temperature industrial processing machinery.

Superior Chemical and Corrosion Resistance

PTFE is a chemically inert substance.

This means it is highly resistant to almost all industrial chemicals, solvents, and corrosive agents. This prevents degradation and corrosion that would destroy metallic bearings.

This inertness makes them indispensable in chemical processing, food and beverage, and pharmaceutical applications where contamination or material breakdown is unacceptable.

Key Mechanical Properties

Beyond the primary traits, Teflon bearings possess solid mechanical capabilities.

They offer high compressive strength, allowing them to handle significant loads without being crushed. They are also engineered for excellent wear resistance, ensuring a long service life.

Furthermore, they can be designed to withstand high rotational speeds and impact loads, providing versatility in dynamic applications.

Understanding the Trade-offs and Practical Limits

No material is perfect. While Teflon's advantages are significant, a trusted technical evaluation requires acknowledging its operational limitations. Understanding these trade-offs is critical to preventing misapplication.

Susceptibility to Creep (Cold Flow)

The most significant limitation of PTFE is its tendency to "creep" or cold flow.

Under a constant, heavy load—especially at elevated temperatures—the material can slowly and permanently deform. This must be a primary consideration in applications with high static loads.

Higher Thermal Expansion

Compared to metals, PTFE has a higher coefficient of thermal expansion.

This means it expands and contracts more significantly with temperature changes. Designers must account for this by engineering proper clearances to prevent binding or failure in applications with wide temperature swings.

The Importance of Proper Installation

The performance of a Teflon bearing is highly dependent on correct installation.

Misalignment or contamination with abrasive particles during installation can damage the relatively soft bearing surface, leading to premature wear and failure. Ensuring shafts and housings are clean and properly aligned is non-negotiable.

How to Apply This to Your Project

Selecting the right bearing involves matching these characteristics to the specific demands of your system. Ask these critical questions.

Analyze Your Load and Speed Requirements

First, define the operational forces. Is the load constant or intermittent? Is it a high-static load where creep could be an issue? Ensure the bearing's specified compressive strength and speed ratings meet your needs.

Evaluate the Operating Environment

What is the full temperature range the bearing will experience? Will it be exposed to moisture, chemicals, or other corrosive agents? The answers to these questions are where Teflon often proves its superiority.

Consider Dimensional Stability

How critical are tight tolerances in your design? If the system will undergo significant temperature fluctuations, you must account for Teflon's thermal expansion in your housing and shaft design to maintain optimal performance.

Making the Right Choice for Your Application

Use these guidelines to determine if a Teflon bearing is the optimal solution for your engineering goal.

- If your primary focus is maintenance-free operation in a harsh chemical or washdown environment: Teflon's self-lubricating and chemically inert properties make it the ideal choice.

- If your primary focus is supporting extremely high, static structural loads for long durations: You must carefully evaluate the risk of creep and may need to consider a bronze or other metallic bearing.

- If your primary focus is reliable performance across extreme temperature fluctuations: Teflon's exceptionally wide and stable operating temperature range makes it a leading contender.

Ultimately, understanding both the strengths and limitations of Teflon bearings empowers you to make a confident and effective design decision.

Summary Table:

| Characteristic | Benefit | Key Consideration |

|---|---|---|

| Extremely Low Friction | Self-lubricating, maintenance-free, smooth operation | Ideal for applications where external lubricants fail |

| Wide Temperature Range | Stable performance from -400°F to +550°F (-240°C to +287°C) | Suitable for cryogenic to high-heat environments |

| Superior Chemical Resistance | Resists almost all industrial chemicals, prevents corrosion | Perfect for harsh chemical, food, and pharmaceutical uses |

| High Compressive Strength | Handles significant loads without being crushed | Evaluate risk of creep (cold flow) under high static loads |

| High Thermal Expansion | - | Requires proper clearance design for temperature swings |

Need a reliable, high-performance Teflon (PTFE) bearing solution for your demanding application?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom bearings, seals, and liners. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you leverage the unique benefits of Teflon—like self-lubrication and chemical inertness—to create a maintenance-free, long-lasting solution.

We work with you from prototype to high-volume production to ensure your component meets exact specifications and performs reliably in even the harshest conditions.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do PTFE coatings prevent component failure? Control Friction and Corrosion for Reliable Performance

- What are the common plumbing applications of PTFE? Ensure Leak-Proof, Durable Seals

- What advantages do PTFE gaskets offer in terms of friction and wear? Achieve Low-Friction, Long-Lasting Seals

- What is Teflon Lined Carbon Steel Pipe, and what are its properties? A Cost-Effective Solution for Corrosive Fluids

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- Why is it important to consider PTFE lining standards when selecting a supplier? Avoid Costly Failures

- What are the benefits of using PTFE valves in the food processing industry? Ensure Safety, Purity, and Efficiency

- How are PTFE Teflon washers used in the automotive industry? Essential for High-Temp, Corrosive Seals