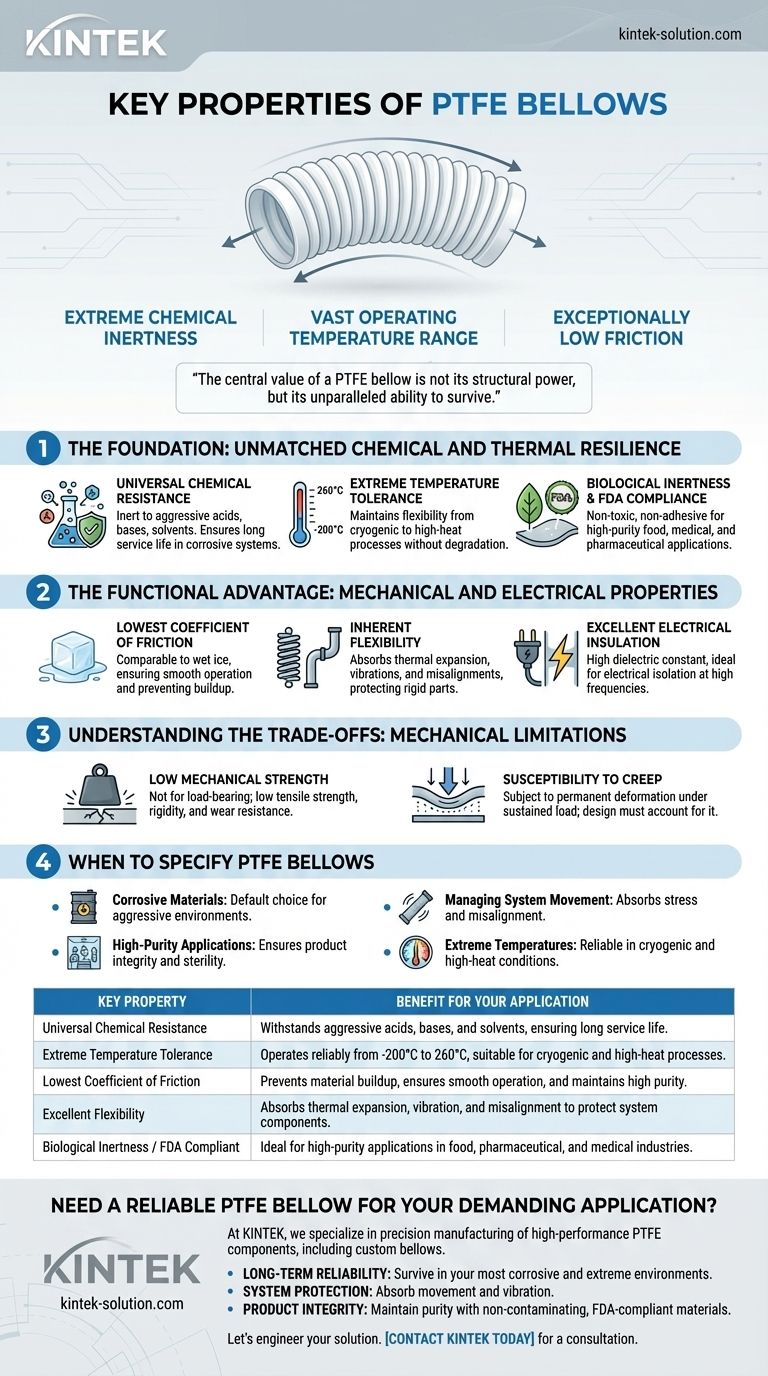

At their core, PTFE bellows are defined by a unique combination of extreme chemical inertness, a vast operating temperature range, and an exceptionally low coefficient of friction. These properties allow them to serve as flexible connectors in demanding industrial environments where most other materials would quickly degrade and fail. They are engineered for resilience, not for mechanical strength.

The central value of a PTFE bellow is not its structural power, but its unparalleled ability to survive. It provides a flexible, non-contaminating, and frictionless seal in systems exposed to corrosive chemicals, extreme temperatures, and high-purity requirements.

The Foundation: Unmatched Chemical and Thermal Resilience

The primary reason engineers specify PTFE is its ability to withstand conditions that would destroy metals, elastomers, and other plastics. This resilience stems from its fundamental material properties.

Universal Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, including the most aggressive acids, bases, and solvents. This makes it a default choice for systems in chemical processing, manufacturing, and laboratory settings.

This inertness ensures the bellow will not corrode or degrade, providing a long service life and reducing maintenance costs and downtime.

Extreme Temperature Tolerance

PTFE bellows maintain their integrity and flexibility across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This allows them to be used in cryogenic applications without becoming brittle and in high-heat processes without melting or losing their essential properties.

Biological Inertness and FDA Compliance

The material is inherently non-toxic and biologically inert, making it compliant with FDA standards for food and medical applications.

Its surface is also non-adhesive, meaning materials do not stick to it. This "non-stick" property is critical in food, pharmaceutical, and biotech industries, as it prevents deposit buildup, reduces blockages, and allows for easy sterilization.

The Functional Advantage: Mechanical and Electrical Properties

Beyond simple survival, PTFE bellows perform critical functions within a system, enabled by their unique mechanical and electrical characteristics.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This ensures extremely smooth operation and prevents material from sticking or building up on its surface.

This property is crucial for maintaining efficient fluid flow and preventing contamination or blockages within a pipeline.

Inherent Flexibility

The bellow design leverages PTFE's flexibility to absorb movement within a system. This includes thermal expansion and contraction of pipelines, mechanical vibrations, and minor misalignments between components.

By absorbing this movement, the bellow protects more rigid and expensive parts of the system from stress, fatigue, and premature failure.

Excellent Electrical Insulation

PTFE is an exceptional electrical insulator with a very low dielectric constant, even at high radio frequencies. This makes it an ideal material for applications where components must be electrically isolated from one another.

Non-Flammability

As a final safety benefit, PTFE is non-flammable and will not contribute to the spread of a fire, a critical feature in many industrial plant environments.

Understanding the Trade-offs: The Mechanical Limitations of PTFE

Trusting a material requires understanding not just its strengths, but also its limitations. While its chemical and thermal properties are elite, PTFE is not a high-strength structural material.

Low Mechanical Strength

Compared to metals or even other engineering plastics, PTFE has relatively low tensile strength, rigidity, and wear resistance. It is not designed for load-bearing applications.

Its purpose is to act as a flexible, resilient seal, not a structural support. External reinforcement is sometimes required in high-pressure applications.

Susceptibility to Creep

Under a constant, sustained load, PTFE can be subject to "creep," which is a tendency to slowly and permanently deform over time. System design must account for this behavior to ensure long-term sealing integrity.

When to Specify PTFE Bellows

Choosing the right material is about matching its properties to your primary goal. Use this guide to determine if PTFE bellows are the correct solution for your application.

- If your primary focus is handling corrosive materials: PTFE's universal chemical inertness makes it the default choice for aggressive acids, bases, and solvents.

- If your primary focus is high-purity applications: Its FDA compliance, biological inertness, and non-stick surface ensure product integrity in food, medical, and pharmaceutical systems.

- If your primary focus is managing system movement: The bellow's flexibility absorbs thermal expansion, vibration, and minor misalignment, protecting the entire pipeline from stress.

- If your primary focus is operating in extreme temperatures: PTFE maintains its properties in both cryogenic and high-heat environments where other elastomers or plastics would fail.

Ultimately, choosing PTFE bellows is a strategic decision for achieving reliability and longevity in your most demanding operational environments.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Universal Chemical Resistance | Withstands aggressive acids, bases, and solvents, ensuring long service life. |

| Extreme Temperature Tolerance | Operates reliably from -200°C to 260°C, suitable for cryogenic and high-heat processes. |

| Lowest Coefficient of Friction | Prevents material buildup, ensures smooth operation, and maintains high purity. |

| Excellent Flexibility | Absorbs thermal expansion, vibration, and misalignment to protect system components. |

| Biological Inertness / FDA Compliant | Ideal for high-purity applications in food, pharmaceutical, and medical industries. |

Need a Reliable PTFE Bellow for Your Demanding Application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom bellows. Our expertise ensures you get a solution that delivers:

- Long-Term Reliability: Survive in your most corrosive and extreme temperature environments.

- System Protection: Absorb movement and vibration to prevent stress on critical equipment.

- Product Integrity: Maintain purity in sensitive processes with our non-contaminating, FDA-compliant materials.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Let's engineer your solution. Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability