Machined Teflon, or PTFE, is ubiquitous in demanding industries where other materials fail. Its most common applications are components that require extreme chemical resistance, very low friction, or high electrical insulation, including parts like seals, gaskets, bearings, bushings, and valve components for the aerospace, medical, and chemical processing sectors.

The core reason PTFE is so widely machined for critical parts is not a single property, but its unique combination of capabilities. It is one of the most chemically inert, lowest-friction, and best electrical insulating materials available, making it a powerful problem-solver for complex engineering challenges.

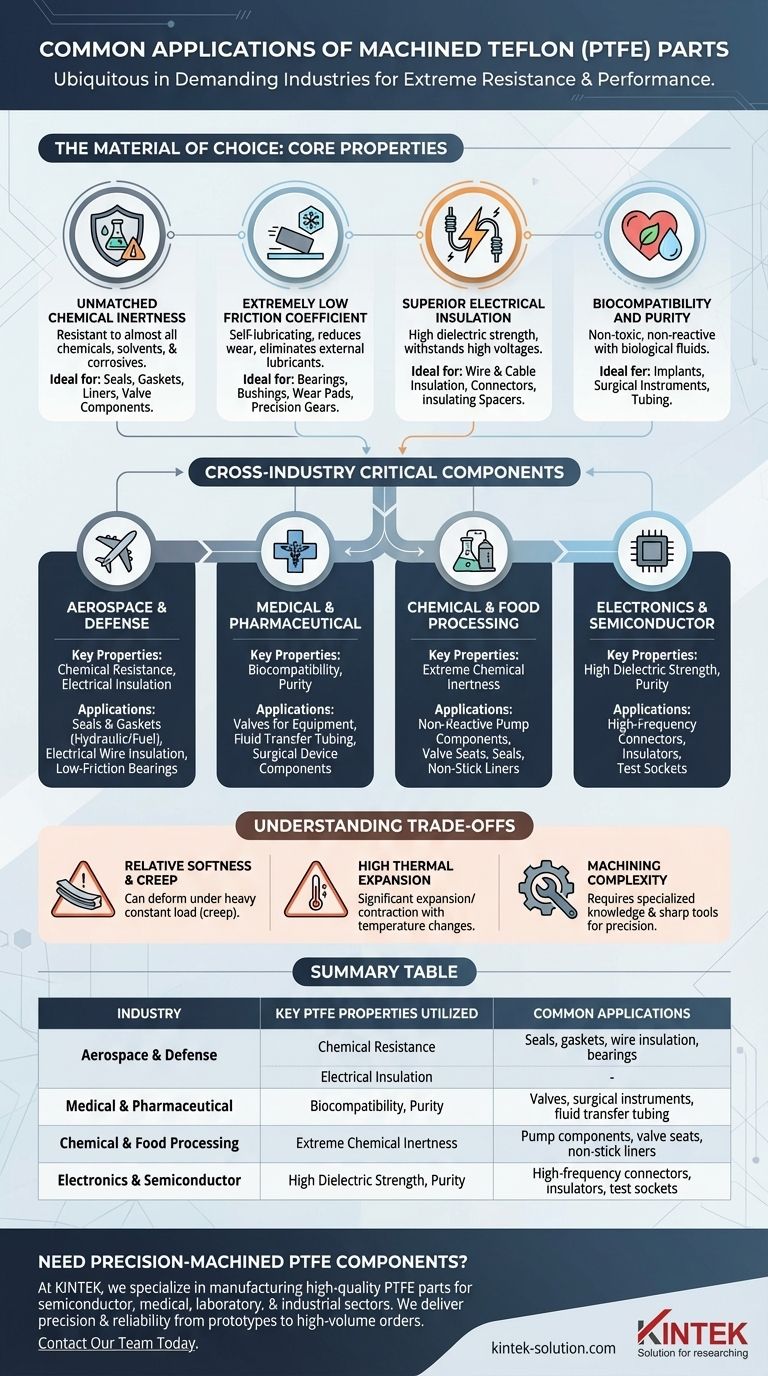

Why PTFE is the Material of Choice: The Core Properties

To understand its applications, you must first understand the fundamental properties that make machined PTFE so valuable. These characteristics directly dictate where and why it is used.

Unmatched Chemical Inertness

PTFE is virtually immune to attack by almost all chemicals, solvents, and corrosive agents. This non-reactivity is critical in harsh environments.

This property makes it the gold standard for seals, gaskets, liners, and valve components in the chemical and food processing industries, where material purity and resistance to degradation are paramount.

Extremely Low Friction Coefficient

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This allows it to function as a self-lubricating surface.

This is why it's extensively used for bearings, bushings, wear pads, and precision gears in automotive and general mechanical applications, reducing wear and eliminating the need for external lubricants.

Superior Electrical Insulation

With exceptionally high dielectric strength, PTFE is an outstanding electrical insulator. It does not conduct electricity and can withstand high voltages.

This makes it indispensable in the aerospace and electronics industries for wire and cable insulation, connectors, and insulating spacers in high-performance electrical systems.

Biocompatibility and Purity

PTFE is non-toxic and biocompatible, meaning it does not react with biological fluids and is not harmful to living tissue.

This purity is essential for the medical field, where it is machined into implants, surgical instruments, and tubing for sterile fluid handling systems.

A Cross-Industry Look at Common Applications

The properties of PTFE translate into critical components across several key industries.

In Aerospace and Defense

In this sector, reliability under extreme conditions is non-negotiable. PTFE is used for seals and gaskets in hydraulic and fuel systems, electrical wire insulation, and low-friction bearings in control linkages.

In Medical and Pharmaceutical

Biocompatibility and sterilizability are the driving factors here. Common parts include valves for medical equipment, tubing for fluid transfer, and components for surgical devices that must not react with the human body.

In Chemical and Food Processing

The primary need is preventing contamination and resisting corrosion. PTFE is machined into non-reactive pump components, valve seats, seals, and non-stick liners for processing equipment.

In Electronics and Semiconductor

High purity and excellent insulating properties are essential. Machined PTFE is used for insulators in high-frequency connectors, test sockets, and components for semiconductor manufacturing equipment where chemical resistance is also vital.

Understanding the Trade-offs of Machined PTFE

No material is perfect. Being a trusted advisor means acknowledging a material's limitations to ensure it is used correctly.

Relative Softness and Creep

PTFE is a relatively soft material. Under a constant, heavy load, it can slowly deform over time in a process known as "creep." This makes it unsuitable for high-load structural applications without reinforcement.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals. This high coefficient of thermal expansion must be accounted for in designs where tight tolerances are critical across a range of temperatures.

Machining Complexity

While machinable, PTFE's softness requires specialized knowledge to achieve precision. Sharp tools, specific cutting speeds, and proper support are necessary to prevent deformation and ensure accurate dimensions.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the primary problem you need to solve.

- If your primary focus is extreme chemical resistance: PTFE is an industry-standard choice for seals, liners, and fluid-handling components in corrosive environments.

- If your primary focus is low friction without lubrication: It is a top-tier material for self-lubricating bearings, bushings, and sliding components.

- If your primary focus is high-performance electrical insulation: Its high dielectric strength makes it ideal for connectors and insulators, especially at high frequencies.

- If your primary focus is biocompatibility and purity: Its inert nature is critical for components used in medical devices and food processing machinery.

By understanding its unique profile of strengths and limitations, you can confidently leverage machined PTFE for the most demanding applications.

Summary Table:

| Industry | Key PTFE Properties Utilized | Common Applications |

|---|---|---|

| Aerospace & Defense | Chemical Resistance, Electrical Insulation | Seals, gaskets, wire insulation, bearings |

| Medical & Pharmaceutical | Biocompatibility, Purity | Valves, surgical instruments, fluid transfer tubing |

| Chemical & Food Processing | Extreme Chemical Inertness | Pump components, valve seats, non-stick liners |

| Electronics & Semiconductor | High Dielectric Strength, Purity | High-frequency connectors, insulators, test sockets |

Need precision-machined PTFE components for your critical application?

At KINTEK, we specialize in manufacturing high-quality PTFE parts—including seals, liners, labware, and custom components—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts meet the highest standards for chemical resistance, low friction, and electrical insulation.

From prototypes to high-volume orders, we deliver precision and reliability. Contact our team today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What role do Teflon rods play in the electrical and electronics industry? Ensure Superior Insulation and Reliability

- What makes PTFE plugs durable? Unmatched Chemical and Temperature Resistance

- What are the advantages of PTFE bushings? Achieve Maintenance-Free, High-Performance Operation

- What are the temperature limitations of Teflon packing? Ensure Sealing Integrity from -200°C to 260°C

- What are the common challenges in machining intricate PTFE components? Overcome Material Instability & Burrs

- How do PTFE-lined valves benefit the environment? Prevent Pollution and Reduce Waste

- What are some common applications of PTFE washers? Ideal for Sealing, Insulation, and Low-Friction Needs

- Why are PTFE envelope gaskets suitable for high temperature-pressure conditions? Superior Sealing for Extreme Applications