In the electrical and electronics industry, Teflon rods serve a critical role as a high-performance electrical insulator. Their primary function is to isolate conductive components, prevent current leakage, and ensure the operational integrity and safety of electrical systems, especially in demanding high-frequency or high-temperature environments.

The core value of Teflon in electronics is not just that it's an insulator, but that it maintains its exceptional insulating properties under thermal, chemical, and electrical stress where lesser materials would fail.

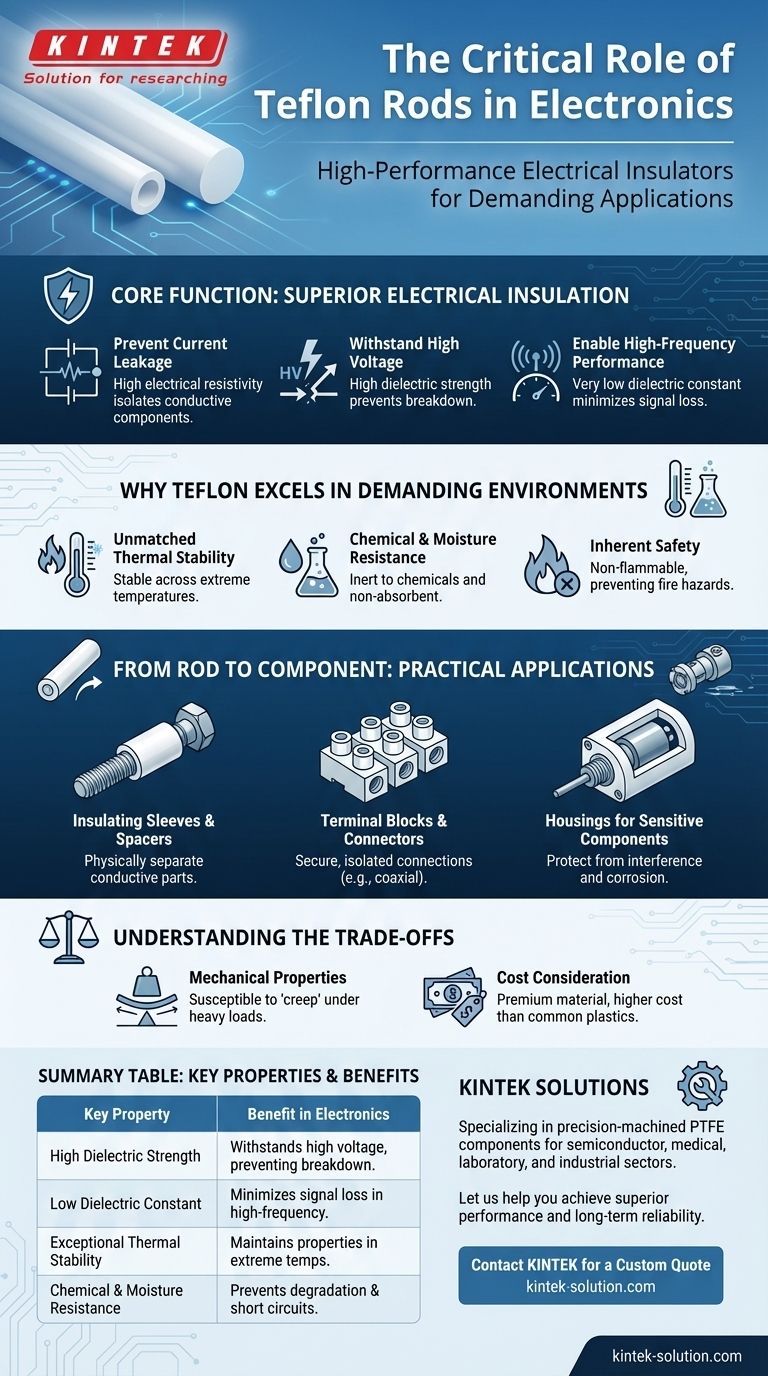

The Core Function: Superior Electrical Insulation

The fundamental purpose of an insulator is to resist the flow of electricity. Teflon, or Polytetrafluoroethylene (PTFE), accomplishes this with remarkable effectiveness due to a unique combination of electrical properties.

Preventing Current Leakage

Teflon possesses extremely high electrical resistivity. This means it strongly opposes the movement of electric current, making it ideal for physically separating and isolating wires, terminals, and circuits from one another.

Withstanding High Voltage

A key property is Teflon's high dielectric strength. This is a measure of how much voltage an insulating material can withstand before it breaks down and allows current to pass through. Teflon's strength in this area makes it essential for high-voltage applications.

Enabling High-Frequency Performance

Teflon has a very low dielectric constant. In simple terms, this means it stores very little electrical energy when exposed to an electric field. This is critical in high-frequency electronics (like radio or radar systems) because it minimizes signal loss and distortion, ensuring signal integrity.

Why Teflon Excels in Demanding Environments

Many plastics can insulate, but few can perform reliably under the harsh conditions common in advanced electronics. Teflon's resilience is what sets it apart.

Unmatched Thermal Stability

Electronic components generate heat, and the operating environment can be hot or cold. Teflon remains stable and retains its insulating properties across an exceptionally wide range of temperatures, preventing failure due to thermal stress.

Chemical and Moisture Resistance

Teflon is famously inert, meaning it does not react with most chemicals. It also does not absorb moisture, which can degrade the insulating capabilities of other materials and lead to short circuits.

Inherent Safety

Teflon is non-flammable, which is a crucial safety characteristic for any material used in electrical systems where there is a risk of overheating or sparks.

From Rod to Component: Practical Applications

Teflon rods are a raw material format that is machined into precise components for specific electronic assemblies.

Insulating Sleeves and Spacers

These are common components created from Teflon rods. They are used to physically separate conductive parts, such as screws, wires, or circuit board layers, ensuring no unintended electrical contact occurs.

Terminal Blocks and Connectors

Terminal blocks provide a secure point for connecting wires. Using Teflon ensures each terminal is perfectly isolated from its neighbors, even in compact, high-density designs. It's especially valued for high-frequency coaxial connectors.

Housings for Sensitive Components

In some cases, entire electronic sensors or components are housed in Teflon casings to protect them not only from electrical interference but also from corrosive chemicals or extreme temperatures.

Understanding the Trade-offs

While Teflon is a superior performer, it is not the universal solution for all applications. Objective technical assessment requires acknowledging its limitations.

Mechanical Properties

Teflon is a relatively soft material. Under a constant, heavy load, it can be susceptible to "creep," or slow deformation over time. This makes it less suitable for high-stress structural roles where mechanical rigidity is the primary requirement.

Cost Consideration

High performance comes at a price. Teflon is a premium material and is significantly more expensive than common insulating plastics like PVC or polyethylene. Its use is therefore justified in applications where its specific properties are mission-critical.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary engineering goal.

- If your primary focus is high-voltage insulation: Teflon's high dielectric strength provides a reliable safeguard against electrical breakdown.

- If you are designing high-frequency electronics: Its low dielectric constant is essential for maintaining signal integrity and minimizing power loss.

- If the component will operate in extreme temperatures or harsh chemical environments: Teflon's thermal stability and inertness offer durability that few other materials can match.

- If cost is the main driver for a standard, low-stress application: You may find that more common and less expensive insulating plastics are sufficient.

Ultimately, choosing Teflon is a decision to prioritize performance and long-term reliability where operating conditions are too demanding for conventional insulators.

Summary Table:

| Key Property | Benefit in Electronics |

|---|---|

| High Dielectric Strength | Withstands high voltage, preventing electrical breakdown. |

| Low Dielectric Constant | Minimizes signal loss in high-frequency applications. |

| Exceptional Thermal Stability | Maintains insulating properties in extreme temperatures. |

| Chemical & Moisture Resistance | Prevents degradation and short circuits in harsh environments. |

Need a reliable insulator for a demanding application?

KINTEK specializes in precision-machined PTFE (Teflon) components—from insulating sleeves and spacers to custom connectors and housings. We serve the semiconductor, medical, laboratory, and industrial sectors, providing solutions that ensure operational integrity under thermal, chemical, and electrical stress.

Let us help you achieve superior performance and long-term reliability. Contact KINTEK today for a custom quote or to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability