In short, Polytetrafluoroethylene (PTFE) washers are commonly used in plumbing for sealing, electronics for insulation, mechanical assemblies for distributing loads, and the food industry for their non-contaminating properties. Their value comes from a unique combination of chemical inertness, temperature resistance, and an incredibly low coefficient of friction.

The true purpose of a PTFE washer is not just to be a spacer; it's to provide a reliable, non-reactive, and low-friction interface in demanding environments where most other materials would quickly corrode, melt, or seize.

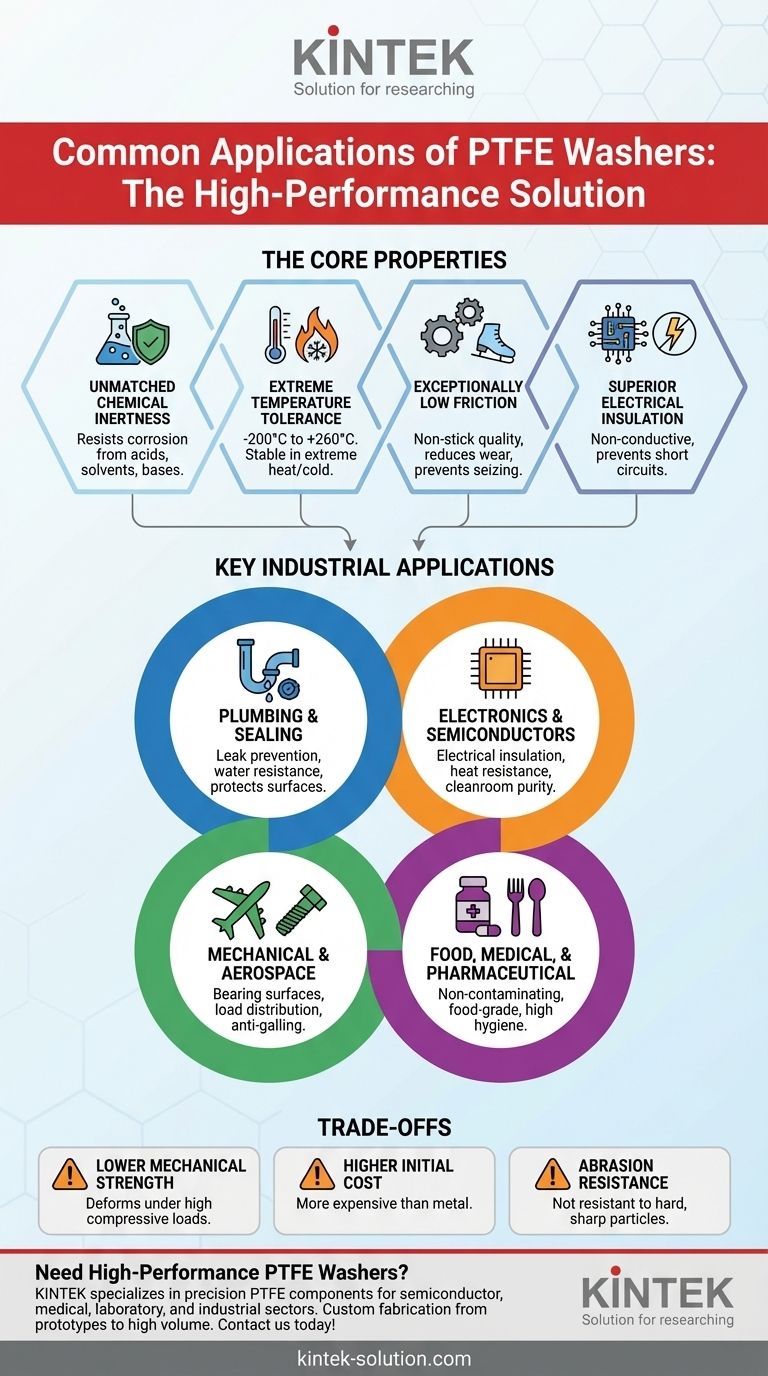

The Core Properties Driving PTFE's Versatility

To understand where PTFE washers are used, you must first understand the fundamental material properties that make them so effective. These characteristics allow them to solve problems that simple metal or rubber washers cannot.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It resists nearly all industrial chemicals, solvents, acids, and bases, preventing corrosion and contamination.

This property makes it indispensable in chemical processing, pharmaceutical production, and any application involving aggressive substances.

Extreme Temperature Tolerance

PTFE washers perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Unlike plastics that become brittle in the cold or metals that can deform under heat, PTFE maintains its integrity in environments like aerospace systems and high-power electronics.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a distinct "non-stick" quality.

This is critical in mechanical assemblies with moving parts, as it reduces wear and prevents galling between surfaces under pressure.

Superior Electrical Insulation

PTFE is an excellent electrical insulator, meaning it does not conduct electricity.

This makes it a primary choice for mounting and isolating components in electronics and semiconductor manufacturing, where it prevents short circuits and protects sensitive parts.

A Breakdown of Key Industrial Applications

The unique properties of PTFE directly translate into its use across a wide array of demanding industries. Each application leverages a specific combination of its strengths.

In Plumbing and Sealing

In plumbing, PTFE washers are used to create a durable seal under bolts and fittings. Their water resistance and ability to conform to surfaces prevent leaks.

They also protect delicate surfaces like porcelain or chrome from being scratched or cracked by metal fasteners.

In Electronics and Semiconductors

Here, the primary roles are electrical insulation and heat resistance. PTFE washers isolate circuit boards from metal chassis and protect components from heat damage.

Their purity and non-contaminating nature are also vital in the cleanroom environments required for semiconductor production.

In Mechanical and Aerospace Assemblies

PTFE washers act as bearing surfaces and load distributors. Placing one under the head of a screw ensures that the clamping force is spread evenly without damaging the underlying material.

Its low-friction surface reduces the torque needed to tighten a fastener and prevents parts from seizing up due to vibration or thermal expansion, a critical factor in aerospace.

In Food, Medical, and Pharmaceutical Industries

PTFE is often available in food-grade and biocompatible formulations. Its non-contaminating surface will not react with or impart any taste to products.

Furthermore, its high resistance to aggressive cleaning chemicals and high-temperature sterilization processes makes it durable and long-lasting in sanitary environments.

Understanding the Trade-offs

While incredibly versatile, PTFE is not the solution for every problem. Understanding its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to steel or other metal washers, PTFE is a relatively soft material. Under extremely high compressive loads, it can deform or "creep" over time.

Higher Initial Cost

A PTFE washer is generally more expensive than a standard zinc-plated steel washer. Its cost-effectiveness comes from its longevity and performance in harsh environments where a cheaper alternative would fail, leading to more costly system damage or downtime.

Abrasion Resistance

While PTFE has low friction, it is not as resistant to direct abrasion from sharp or hard particles as materials like ceramic or hardened steel.

Making the Right Choice for Your Application

Selecting the correct washer depends entirely on the specific demands of your environment and the problem you need to solve.

- If your primary focus is sealing against harsh chemicals or extreme temperatures: PTFE is almost certainly the correct choice due to its inertness and thermal stability.

- If your primary focus is electrical insulation for sensitive components: PTFE's dielectric properties make it a premier solution.

- If your primary focus is reducing friction between fastened moving parts: A PTFE washer is an excellent option to serve as a low-wear slip surface.

- If your primary focus is high-strength load distribution in a stable environment: A standard metal washer will likely provide the necessary strength more cost-effectively.

Ultimately, a PTFE washer is a specialized component engineered to succeed where conventional materials fail.

Summary Table:

| Property | Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists corrosion from acids, solvents | Chemical processing, pharmaceuticals |

| Temperature Resistance | Stable from -200°C to +260°C | Aerospace, high-power electronics |

| Low Friction | Reduces wear, prevents seizing | Mechanical assemblies with moving parts |

| Electrical Insulation | Prevents short circuits | Electronics, semiconductor manufacturing |

| Non-Contaminating | Safe for sensitive environments | Food, medical, and pharmaceutical industries |

Need a high-performance PTFE washer for your specific application? KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your demanding environment. Contact us today to discuss your project and experience the KINTEK difference in quality and reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications