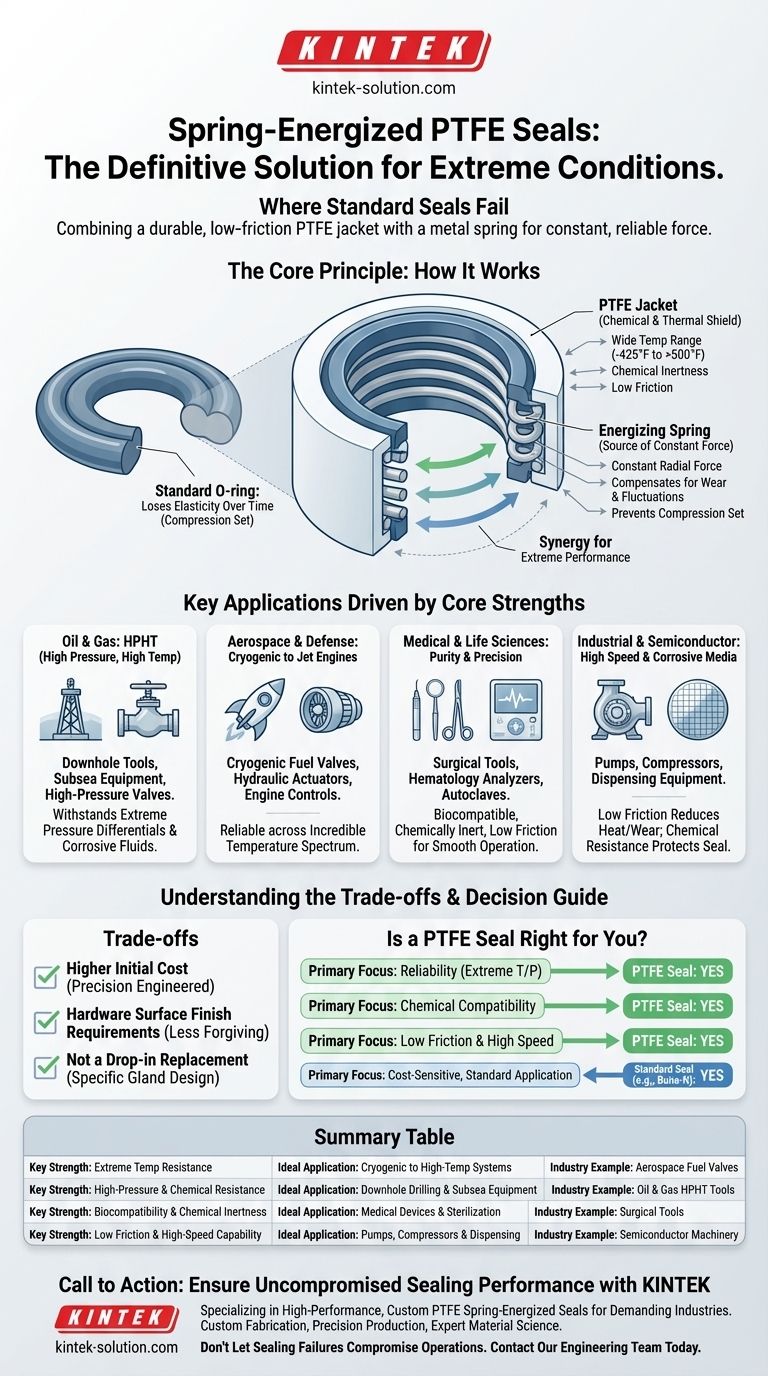

Spring-energized PTFE seals are the definitive solution for sealing challenges where conventional seals fail. They are specifically engineered for applications involving extreme conditions, such as cryogenic to high temperatures, high pressures, high speeds, and aggressive chemical environments. Their unique design provides a reliable seal in static, reciprocating, and rotary applications where standard elastomeric seals would quickly degrade or lose their sealing force.

The fundamental problem with many sealing applications is that standard seals lose their elasticity and sealing force over time, especially under thermal or chemical stress. Spring-energized seals solve this by combining a durable, low-friction PTFE jacket with a metal spring, which provides constant mechanical pressure to ensure a reliable seal for the life of the component.

The Core Principle: Why This Design Works

To understand the applications for these seals, you must first understand their fundamental design. It is a synergy between two distinct materials that creates a high-performance sealing system.

The PTFE Jacket: The Chemical and Thermal Shield

The outer seal jacket is made from Polytetrafluoroethylene (PTFE), a fluoropolymer more commonly known by the brand name Teflon™. This material provides the primary interface with the hardware and the sealed media.

PTFE is chosen for its exceptional properties, including a very low friction coefficient, near-universal chemical compatibility, and an extremely wide operating temperature range. It can resist almost all industrial chemicals, acids, and solvents.

The Energizing Spring: The Source of Constant Force

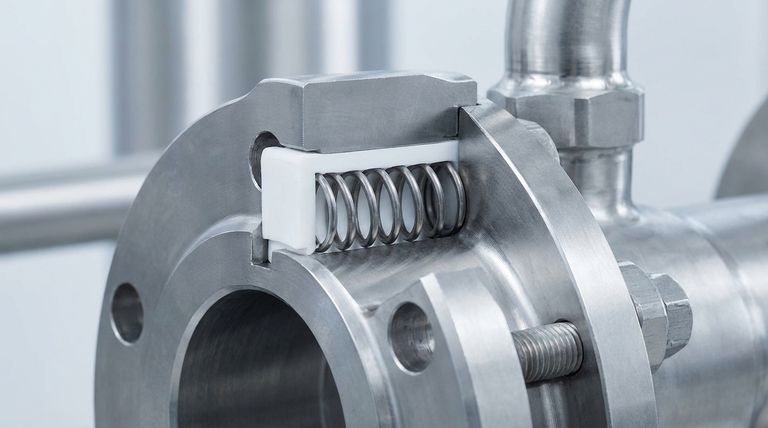

Unlike a standard O-ring, which relies on its own material elasticity to create a seal, a PTFE seal is relatively rigid. The sealing force comes from a high-quality metal spring embedded within the jacket.

This spring exerts a constant, consistent radial force on the PTFE lips, pushing them against the gland and the dynamic sealing surface. This mechanism compensates for material wear, temperature fluctuations, and hardware imperfections, ensuring a tight seal even at very low system pressures. Common spring types include V-springs and canted coil springs.

A Synergy for Extreme Performance

The combination is what makes the seal so effective. The PTFE jacket provides the robust chemical and thermal resistance, while the internal spring provides the permanent elasticity that prevents the seal from taking a compression set—a common failure mode for elastomers.

Key Applications Driven by Core Strengths

The unique capabilities of spring-energized PTFE seals make them essential in industries where failure is not an option.

Oil & Gas: High Pressure, High Temperature (HPHT)

In downhole drilling, subsea equipment, and high-pressure valves, seals must withstand enormous pressure differentials, corrosive fluids, and extreme temperature swings. Spring-energized seals maintain their integrity in these HPHT environments, preventing costly and dangerous leaks in tools, pumps, and valves.

Aerospace & Defense: Reliability from Cryogenics to Jet Engines

Aerospace applications demand performance across an incredible temperature spectrum. These seals are used in cryogenic fuel valves operating at -425°F (-260°C) and in high-temperature turbine engines and hydraulic actuators exceeding 500°F (260°C). They are critical components in landing gear, fuel systems, and engine controls.

Medical & Life Sciences: Purity and Precision

PTFE is biocompatible and chemically inert, making it ideal for medical devices. Spring-energized seals are used in surgical tools, hematology analyzers, and autoclaves where they will not react with bodily fluids or harsh sterilization chemicals. Their low friction is also vital for the smooth operation of precision dispensing equipment.

Industrial & Semiconductor: High Speeds and Corrosive Media

In pumps, compressors, and dispensing equipment, seals face a combination of high-speed movement and corrosive media. The low-friction nature of PTFE reduces heat buildup and wear in dynamic applications, while its chemical resistance protects the seal from degradation, ensuring long service life.

Understanding the Trade-offs

While incredibly capable, these seals are not a universal solution. Objectivity requires acknowledging their specific engineering context.

Higher Initial Cost

Spring-energized PTFE seals are precision-engineered components, not commodity items. Their manufacturing process is more complex than that of a simple molded O-ring, resulting in a higher upfront cost.

Hardware Surface Finish Requirements

Because PTFE is a harder material than rubber, it is less forgiving of imperfections in the mating hardware. Achieving a reliable, long-lasting seal requires a smooth and precise surface finish on the rod or bore to prevent leaks and premature wear.

Not a Drop-in Replacement

These seals cannot simply be swapped into a groove designed for a standard O-ring. They require specific gland and groove dimensions to function correctly. Proper implementation is an engineering task that must account for pressure, temperature, and hardware tolerances.

How to Determine if a PTFE Seal is Right for You

Choosing the correct seal comes down to balancing performance requirements with cost and design constraints.

- If your primary focus is reliability in extreme temperatures or pressures: Spring-energized PTFE seals offer unmatched performance where elastomers would fail or take a compression set.

- If your primary focus is chemical compatibility: The near-universal inertness of PTFE makes these seals the default choice for aggressive chemicals, solvents, and corrosive fluids.

- If your primary focus is low friction and high speed: The naturally low friction coefficient of the PTFE jacket minimizes wear and heat generation in dynamic rotary or reciprocating applications.

- If your primary focus is a cost-sensitive, standard application: A conventional elastomeric seal, like a Buna-N or Viton™ O-ring, is likely a more practical and economical choice for moderate conditions.

Ultimately, choosing a spring-energized PTFE seal is an engineering decision to ensure sealing integrity when performance cannot be compromised.

Summary Table:

| Key Strength | Ideal Application | Industry Example |

|---|---|---|

| Extreme Temperature Resistance | Cryogenic to High-Temperature Systems | Aerospace Fuel Valves & Engine Controls |

| High-Pressure & Chemical Resistance | Downhole Drilling & Subsea Equipment | Oil & Gas HPHT Tools & Valves |

| Biocompatibility & Chemical Inertness | Medical Devices & Sterilization Equipment | Surgical Tools & Analyzers |

| Low Friction & High-Speed Capability | Pumps, Compressors & Dispensing Systems | Semiconductor & Industrial Machinery |

Ensure Uncompromised Sealing Performance with KINTEK

When your application demands reliability in the face of extreme temperatures, aggressive chemicals, or high-speed dynamics, a standard seal is not enough. You need a precision-engineered solution.

KINTEK specializes in manufacturing high-performance PTFE components, including custom spring-energized seals. We serve demanding industries like semiconductor, medical, laboratory, and industrial sectors, where failure is not an option.

We partner with you to deliver:

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Precision Production: Ensuring every seal meets exact specifications for a perfect fit and long-lasting performance.

- Expert Material Science: Leveraging PTFE's superior properties to solve your unique sealing challenges.

Don't let sealing failures compromise your critical operations. Contact our engineering team today to discuss your application requirements and discover how our custom PTFE seals can provide the reliable, long-term solution you need.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- In which industries are PTFE bushes commonly used? A Guide to High-Performance Applications

- What makes machined PTFE suitable for industrial applications? Unmatched Performance in Extreme Conditions

- What post-machining processes can improve PTFE surface finishes? Achieve a Flawless Finish for Your Components

- How does the low friction property of PTFE benefit O-rings? Extend Seal Life and Boost Efficiency

- What are the common grades of PTFE used in machining? Choose the Right Grade for Your Application

- What are some common alternatives to Teflon sheets for heat press applications? Find the Right Protective Sheet

- How do PTFE O-rings function? A Guide to High-Performance Sealing in Demanding Environments

- What are the high temperature capabilities of PTFE seals? Maximize Performance Up to 600°F (316°C)