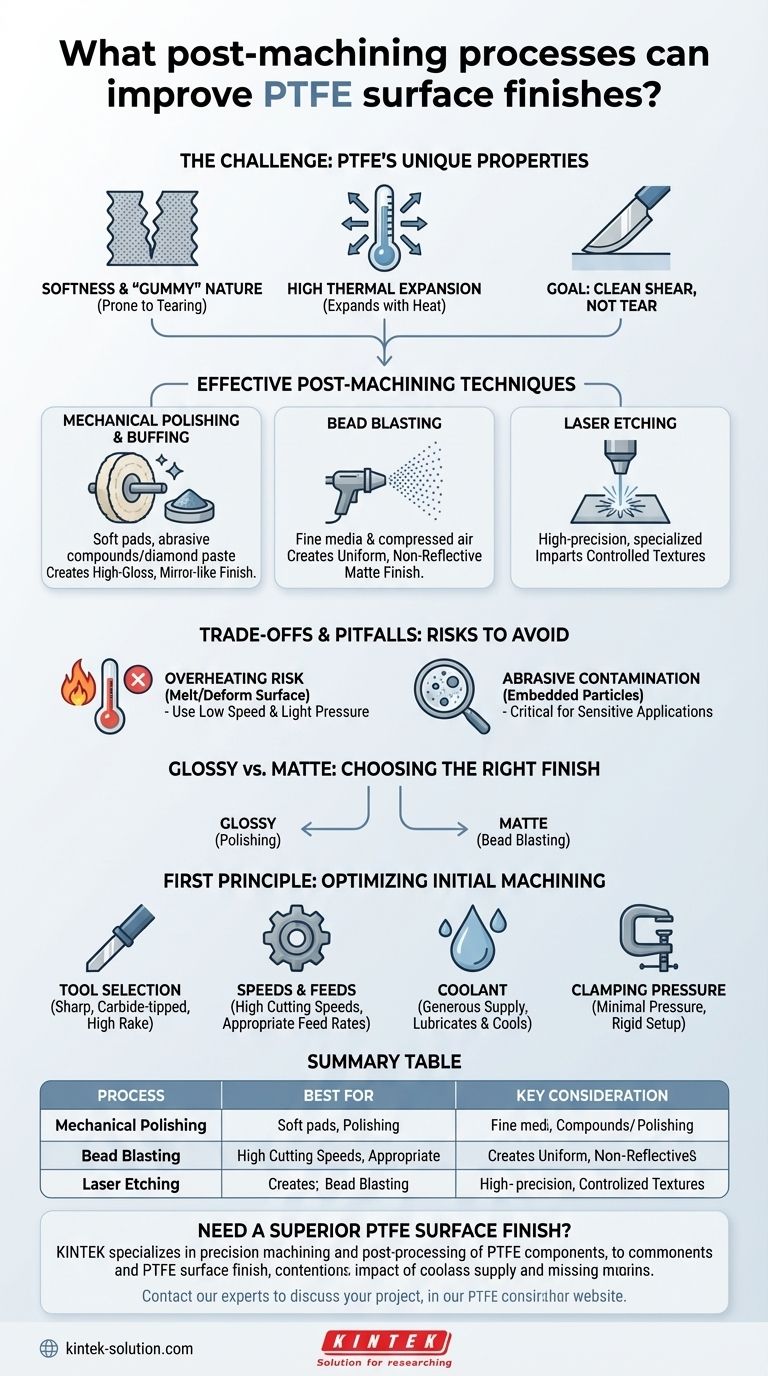

To improve the surface finish of a machined PTFE part, the most effective post-processing methods are mechanical polishing, buffing with fine abrasive compounds, and bead blasting. These techniques are used to refine the rough or torn surfaces that can result from the initial cutting process, significantly enhancing the final quality and appearance of the component.

PTFE’s inherent softness makes it prone to tearing and burring during machining. The key to a superior finish lies not just in post-processing, but in optimizing the initial machining to minimize surface defects before any polishing or blasting begins.

Why PTFE Surface Finishing is a Unique Challenge

Understanding the material's properties is the first step to achieving a high-quality finish. PTFE does not behave like metal or even harder plastics during machining.

The Softness and "Gummy" Nature of PTFE

PTFE is an exceptionally soft material. Instead of producing a clean chip when cut, it has a tendency to tear, smear, or create burrs. This is the primary reason why achieving a smooth, defect-free surface directly from the machine is difficult.

High Thermal Expansion

The material has a high coefficient of thermal expansion and low thermal conductivity. Friction from cutting tools generates heat that can't dissipate quickly, causing the material to expand during machining and contract as it cools, which can ruin dimensional accuracy and surface quality.

The Goal: A Clean Shear, Not a Rough Tear

Effective PTFE machining and finishing aims to shear the material cleanly. This requires extremely sharp tooling and carefully controlled parameters to slice through the material rather than pushing and deforming it.

Effective Post-Machining Finishing Techniques

Once the initial machining is complete, several methods can be employed to refine the surface.

Mechanical Polishing & Buffing

This is the most common method for creating a smooth, often glossy finish. It involves using soft felt pads or buffing wheels in combination with a polishing medium.

Ultra-fine abrasive compounds or diamond paste are highly effective for refining the surface to a high standard.

Bead Blasting

This process uses fine media, such as glass beads, propelled by compressed air to impact the surface. It does not create a glossy finish.

Instead, bead blasting produces a uniform, non-reflective matte texture. This is ideal for applications where consistency is more important than shine and for removing minor machining marks across the entire part.

Laser Etching

While less common for general smoothing, laser etching can be used to impart a specific, controlled texture onto the surface of a PTFE part. This is a high-precision method typically reserved for specialized applications.

Understanding the Trade-offs and Pitfalls

Post-processing PTFE is not without risks. An incorrect approach can easily damage the part.

The Critical Risk of Overheating

This is the single most important factor to control. The friction from aggressive polishing or buffing can quickly generate enough heat to melt or deform the PTFE surface. This permanently damages the part and its material properties.

Always use low speeds and light pressure during any mechanical polishing process.

Abrasive Contamination

Because PTFE is so soft, particles from abrasive compounds or polishing pads can become embedded in the surface. This can be a major issue for components used in medical, semiconductor, or food-grade applications where purity is critical.

Glossy vs. Matte Finishes

It's essential to match the technique to the desired outcome. Polishing creates a glossy finish by smoothing the surface at a microscopic level. Bead blasting creates a matte finish by creating a uniform pattern of microscopic craters. Choose the method that aligns with your component's requirements.

First Principle: Optimizing the Initial Machining

The best way to ensure a great surface finish is to produce one during the primary machining operation. This minimizes the need for aggressive and risky post-processing.

Tool Selection is Critical

Use only extremely sharp, carbide-tipped tools with a high rake angle and significant relief. A dull or improperly ground tool will tear the material, guaranteeing a poor finish.

Balancing Speeds and Feeds

The goal is to cut the material cleanly without generating excess heat. This typically involves high cutting speeds (200-500 surface feet per minute) and appropriate feed rates (0.002-0.010 inches per revolution) to ensure the tool is constantly moving into fresh material.

The Role of Coolant

Using a generous supply of coolant is non-negotiable. It serves two purposes: it lubricates the cutting edge to prevent material from sticking to the tool, and it carries away heat to prevent thermal expansion and melting.

Clamping Pressure and Stability

Apply minimal clamping pressure to hold the workpiece. Excessive pressure will easily distort the soft PTFE, leading to dimensional inaccuracies. Ensure the setup is rigid to avoid any vibration, which contributes to a poor surface finish.

Making the Right Choice for Your Application

Your final goal determines the best finishing strategy.

- If your primary focus is achieving a high-gloss, mirror-like surface: Mechanical polishing with diamond paste is your best method, but you must control heat meticulously with low speeds and light pressure.

- If your primary focus is a uniform, non-reflective matte finish: Bead blasting is the most effective and repeatable process.

- If your primary focus is preventing surface defects in the first place: Prioritize optimizing your machining parameters with sharp tools and effective cooling, as this will drastically reduce the need for any post-processing.

By treating the machining and finishing of PTFE as a single, connected process, you gain full control over the final quality and performance of your component.

Summary Table:

| Post-Machining Process | Best For | Key Consideration |

|---|---|---|

| Mechanical Polishing & Buffing | High-gloss, mirror-like finishes | Risk of overheating; use low speed/light pressure |

| Bead Blasting | Uniform, non-reflective matte finishes | Ideal for consistency and removing minor marks |

| Laser Etching | Imparting specific, controlled textures | High-precision; for specialized applications |

Need a Superior PTFE Surface Finish for Your Application?

Achieving a flawless finish on PTFE components is critical for performance in demanding industries like semiconductor, medical, and laboratory equipment. KINTEK specializes in the precision machining and post-processing of PTFE components—including seals, liners, and custom labware. We understand the unique challenges of working with PTFE and employ optimized techniques to deliver the exact surface quality your application requires, from prototypes to high-volume orders.

Contact our experts today to discuss your project and discover how we can enhance the quality and performance of your PTFE parts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments