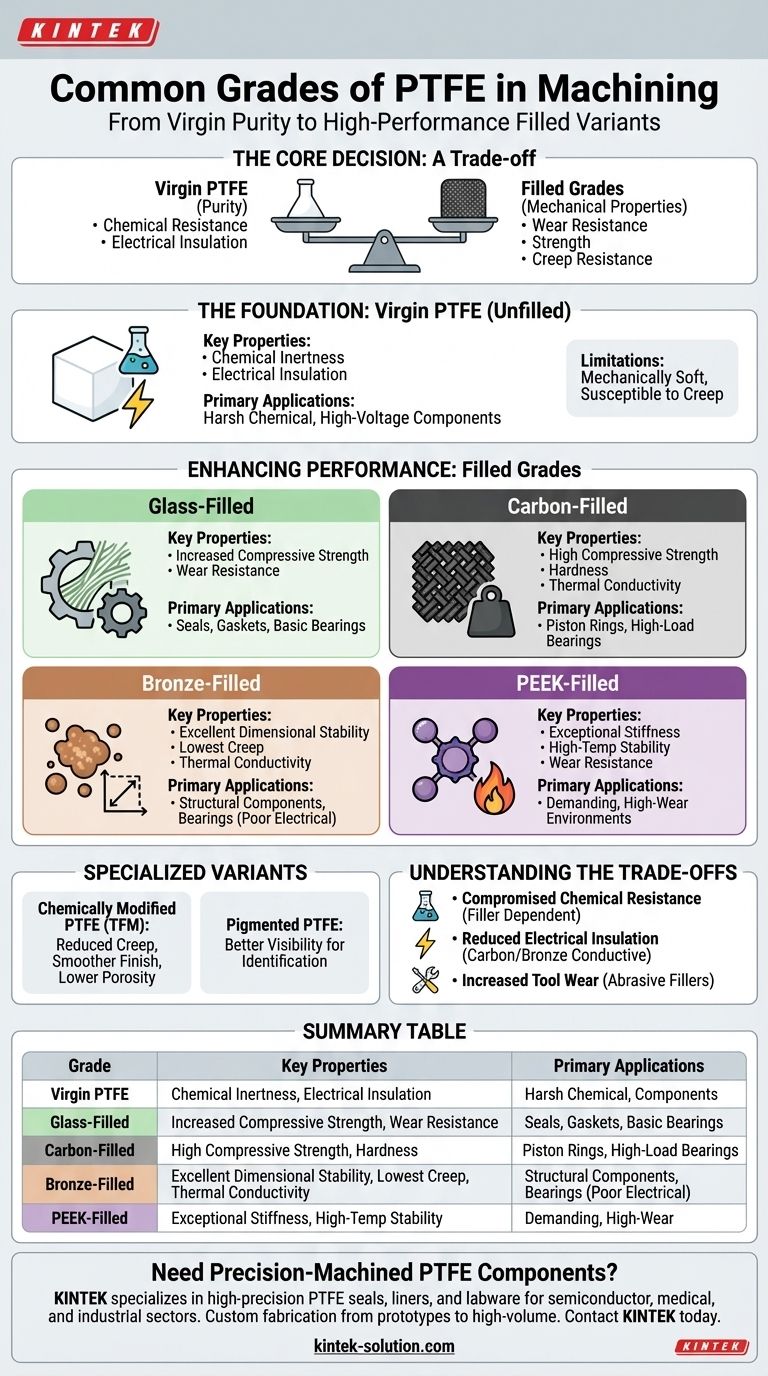

The most common grades of PTFE for machining are Virgin (unfilled) PTFE and several "filled" grades that enhance specific mechanical properties. These include Glass-filled for general-purpose wear resistance, Carbon-filled for compressive strength, Bronze-filled for dimensional stability, and PEEK-filled for high-performance applications where stiffness and durability are critical.

The core decision in selecting a PTFE grade for machining is a trade-off: Virgin PTFE offers the highest chemical resistance and electrical insulation, while filled grades sacrifice some of that purity to dramatically improve mechanical properties like wear resistance, strength, and resistance to deformation under load ("creep").

The Foundation: Virgin PTFE

Unmatched Chemical and Electrical Purity

Virgin Grade PTFE is pure, unmodified Polytetrafluoroethylene. Its defining characteristics are its near-total chemical inertness and exceptional performance as an electrical insulator.

It is the go-to material for components in harsh chemical environments or high-voltage applications where contamination cannot be tolerated.

The Mechanical Limitations

While chemically robust, Virgin PTFE is mechanically soft. It is susceptible to creep (also known as cold flow), where the material slowly deforms under sustained pressure.

Its relatively low wear resistance makes it less suitable for dynamic applications like high-load bearings or seals compared to filled grades.

Enhancing Performance with Filled Grades

Fillers are additives blended into the base PTFE resin before it is processed into stock shapes (rods, tubes, sheets). This fundamentally alters the material's mechanical behavior to suit specific engineering needs.

Glass-Filled PTFE

Reinforced with glass fibers (a common fill is 25%), this grade offers significantly increased compressive strength and wear resistance compared to virgin PTFE.

It's a very common and cost-effective choice for components like seals, gaskets, and basic bearings that need better durability and less deformation under load.

Carbon-Filled PTFE

Adding carbon fiber dramatically increases compressive strength, hardness, and wear resistance, often surpassing glass-filled variants.

Carbon also improves thermal conductivity, helping to dissipate heat in high-speed applications. This makes it ideal for piston rings, bearings, and seals in demanding conditions.

Bronze-Filled PTFE

Bronze filler provides excellent dimensional stability and the lowest creep of all filled PTFE grades. This makes it a superior choice for structural components and bearings.

It also has higher thermal conductivity than glass-filled PTFE, but its electrical properties are poor, making it unsuitable for insulating applications.

PEEK-Filled PTFE

This is a high-performance grade that combines PTFE with Polyetheretherketone (PEEK) filler. The result is a material with exceptional stiffness, high-temperature stability, and wear resistance.

PEEK-filled PTFE is specified for the most demanding environments where parts must withstand high loads and abrasive conditions without failure.

Specialized PTFE Variants

Chemically Modified PTFE (TFM)

This is a second-generation PTFE that modifies the polymer structure itself. The primary benefit is significantly reduced creep and lower porosity.

Machined parts made from TFM have a smoother surface finish and better resistance to permeation, making them ideal for high-purity sealing applications.

Pigmented PTFE

In this grade, pigments are added simply to color the material. This has no significant impact on performance but provides better visibility for part identification or inspection during assembly.

Understanding the Trade-offs

Choosing a filled PTFE grade is not a simple upgrade. Introducing a filler material requires accepting specific compromises.

Compromised Chemical Resistance

While still excellent, the chemical resistance of a filled PTFE is determined by the filler itself. An aggressive chemical that does not affect PTFE might attack the glass or bronze filler, compromising the component.

Reduced Electrical Insulation

Virgin PTFE is an outstanding electrical insulator. Adding conductive fillers like carbon or bronze dramatically reduces its dielectric strength, making these grades entirely unsuitable for electrical applications.

Increased Tool Wear

Filled PTFE grades are more abrasive than Virgin PTFE. Machining these materials will result in faster tool wear, which must be factored into the manufacturing process.

Selecting the Right PTFE for Your Application

Your choice must be driven by the most critical requirement of the final machined part.

- If your primary focus is electrical insulation or maximum chemical purity: Choose Virgin PTFE for its unmatched inertness and dielectric properties.

- If your primary focus is general-purpose wear resistance and strength: Glass-filled PTFE offers a balanced and cost-effective performance upgrade.

- If your primary focus is high compressive strength and thermal conductivity: Carbon-filled PTFE provides superior performance for high-load and high-speed dynamic parts.

- If your primary focus is dimensional stability for bearings or seals: Bronze-filled PTFE excels at resisting creep and maintaining its shape under sustained load.

- If your primary focus is the highest performance in demanding wear environments: PEEK-filled PTFE provides the ultimate stiffness and durability for critical applications.

By understanding the distinct advantages and inherent trade-offs of each grade, you can confidently select the precise material your project demands.

Summary Table:

| Grade | Key Properties | Primary Applications |

|---|---|---|

| Virgin PTFE | Chemical inertness, electrical insulation | Chemical processing, electrical components |

| Glass-Filled | Wear resistance, compressive strength | Seals, gaskets, basic bearings |

| Carbon-Filled | High compressive strength, thermal conductivity | Piston rings, high-load bearings |

| Bronze-Filled | Dimensional stability, low creep | Structural components, bearings |

| PEEK-Filled | Stiffness, high-temperature stability | Demanding, high-wear environments |

Need Precision-Machined PTFE Components?

Selecting the right PTFE grade is critical for performance and longevity. KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications. Let our expertise guide you to the optimal material solution.

Contact KINTEK today for a consultation and quote.

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the machining advantages of PTFE rod? Achieve Cost-Effective, Complex Parts

- What are PTFE rods and how are they manufactured? A Guide to Their Properties and Production

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems

- How are PTFE extruded rods applied in the food processing industry? Enhancing Hygiene and Efficiency

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.