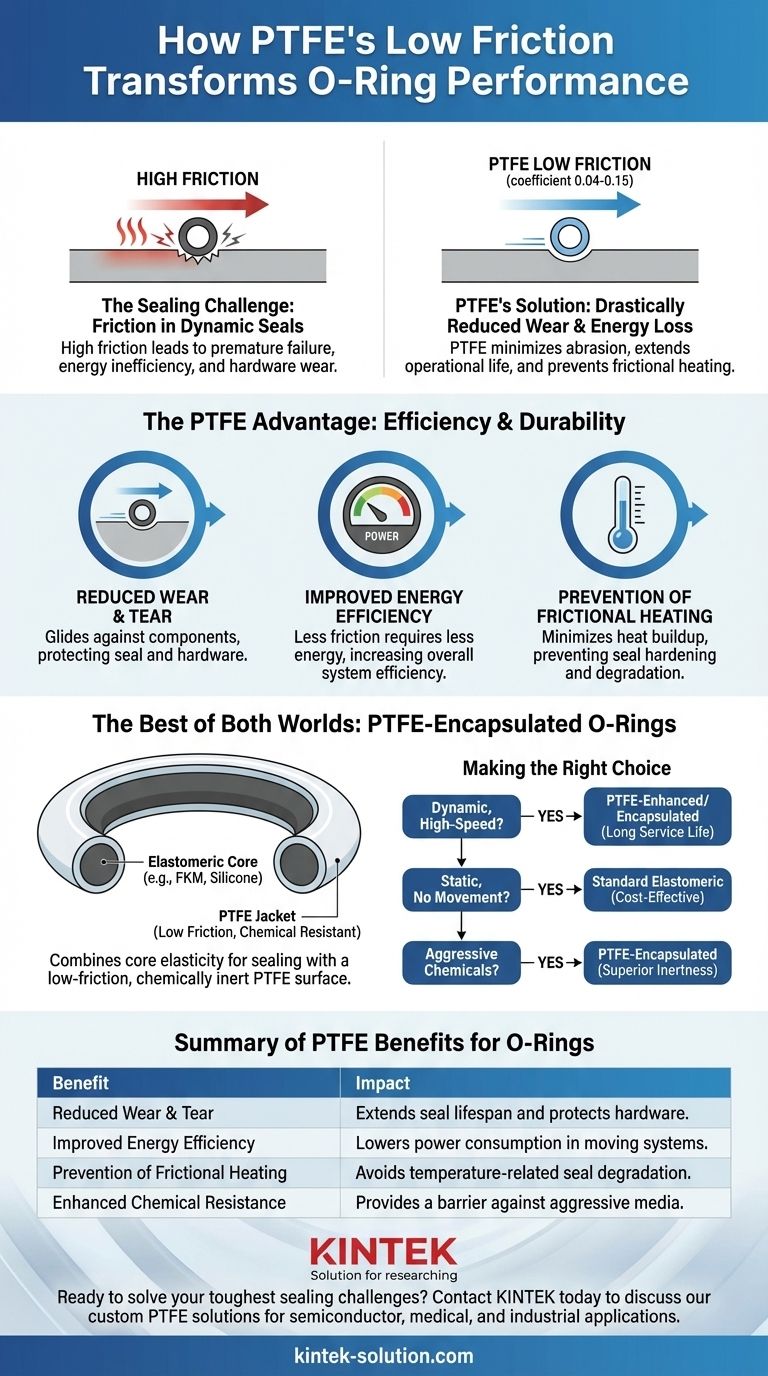

In short, the low-friction property of PTFE dramatically extends the life of O-rings by reducing wear and tear in moving systems. This characteristic also lowers energy consumption by minimizing resistance, making it essential for high-performance dynamic sealing applications.

The core benefit is not just about making a surface "slippery." It's about fundamentally changing the interaction between the seal and the moving parts, transforming a point of high wear and energy loss into a highly efficient and durable interface.

The Sealing Challenge: Pressure vs. Movement

An O-ring's primary job is to create a barrier. It achieves this by being compressed into a groove between two surfaces, physically blocking the path of fluids or gases.

The Problem with Dynamic Seals

In a static seal, the parts don't move relative to each other, and the O-ring simply sits compressed.

In a dynamic seal, one surface moves against the O-ring. This constant rubbing action introduces friction, which is the root cause of several critical engineering problems.

The Consequences of High Friction

High friction in a sealing application leads directly to premature failure and inefficiency. It generates excessive heat, which can degrade the seal material, and it causes abrasive wear on both the O-ring and the hardware it touches. This also wastes energy, as the system must work harder to overcome the frictional resistance.

How PTFE's Low Friction Provides the Solution

Polytetrafluoroethylene (PTFE) has one of the lowest coefficients of friction of any solid material, typically between 0.04 and 0.15. Introducing this property to an O-ring interface fundamentally solves the friction problem.

Drastically Reduced Wear and Tear

With a low-friction surface, the O-ring glides against moving components instead of dragging. This massive reduction in resistance minimizes abrasion, directly extending the operational lifespan of the seal and protecting expensive hardware from damage.

Improved Energy Efficiency

Less friction means less energy is required to move the components. In high-speed machinery like motors, pumps, and actuators, this translates into significant power savings and improved overall system efficiency.

Prevention of Frictional Heating

Friction generates heat. By minimizing friction, a PTFE surface prevents the temperature buildup that can cause traditional rubber O-rings to harden, crack, or otherwise fail, especially in high-velocity applications.

Understanding the Trade-offs: The PTFE-Encapsulated O-ring

While its low friction is a major advantage, a solid PTFE O-ring lacks the elasticity and memory of a traditional rubber seal. It doesn't spring back into shape well after being compressed, a property known as compression set.

The Best of Both Worlds

To overcome this, engineers use PTFE-encapsulated O-rings. These combine a flexible, elastomeric core (like FKM or Silicone) with a thin outer jacket of PTFE.

This design provides the ideal solution: the rubber core delivers the necessary elasticity to maintain a strong seal, while the PTFE jacket provides the low-friction surface and adds a barrier of exceptional chemical resistance.

When a Standard O-ring is Sufficient

For purely static applications or very low-speed dynamic uses where friction is not a primary concern, a standard elastomeric O-ring is often a more cost-effective and perfectly suitable choice.

Making the Right Choice for Your Goal

Selecting the right seal depends entirely on the demands of the application.

- If your primary focus is a high-speed or high-cycle dynamic seal: A PTFE-enhanced or encapsulated O-ring is essential for achieving long service life and system efficiency.

- If your primary focus is a static seal with no movement: A standard elastomeric O-ring provides the best sealing performance for the cost.

- If your primary focus is sealing against aggressive chemicals: A PTFE-encapsulated O-ring offers superior chemical inertness in addition to its low-friction benefits.

By leveraging the unique properties of PTFE, you can design mechanical systems that are not only sealed effectively but are also more durable and efficient.

Summary Table:

| Benefit | Impact on O-Ring Performance |

|---|---|

| Reduced Wear & Tear | Extends seal lifespan and protects hardware. |

| Improved Energy Efficiency | Lowers power consumption in moving systems. |

| Prevention of Frictional Heating | Avoids temperature-related seal degradation. |

| Enhanced Chemical Resistance | Provides a barrier against aggressive media. |

Ready to solve your toughest sealing challenges?

KINTEK specializes in manufacturing high-performance PTFE components, including custom O-rings and seals for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a durable, efficient seal tailored to your exact application needs.

Contact KINTEK today to discuss how our PTFE solutions can extend your equipment's life and improve its efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability