At their core, PTFE laminated membrane filters are the go-to choice for applications involving aggressive chemicals, non-aqueous solvents, and gas or air filtration. Their suitability extends across many fields, including the clarification of solvents, sterile venting, phase separations, and environmental air sampling.

The defining features of PTFE are its extreme chemical inertness and inherent hydrophobicity. This combination makes it the default material for filtering aggressive liquids that would degrade other membranes or for applications where blocking water is essential.

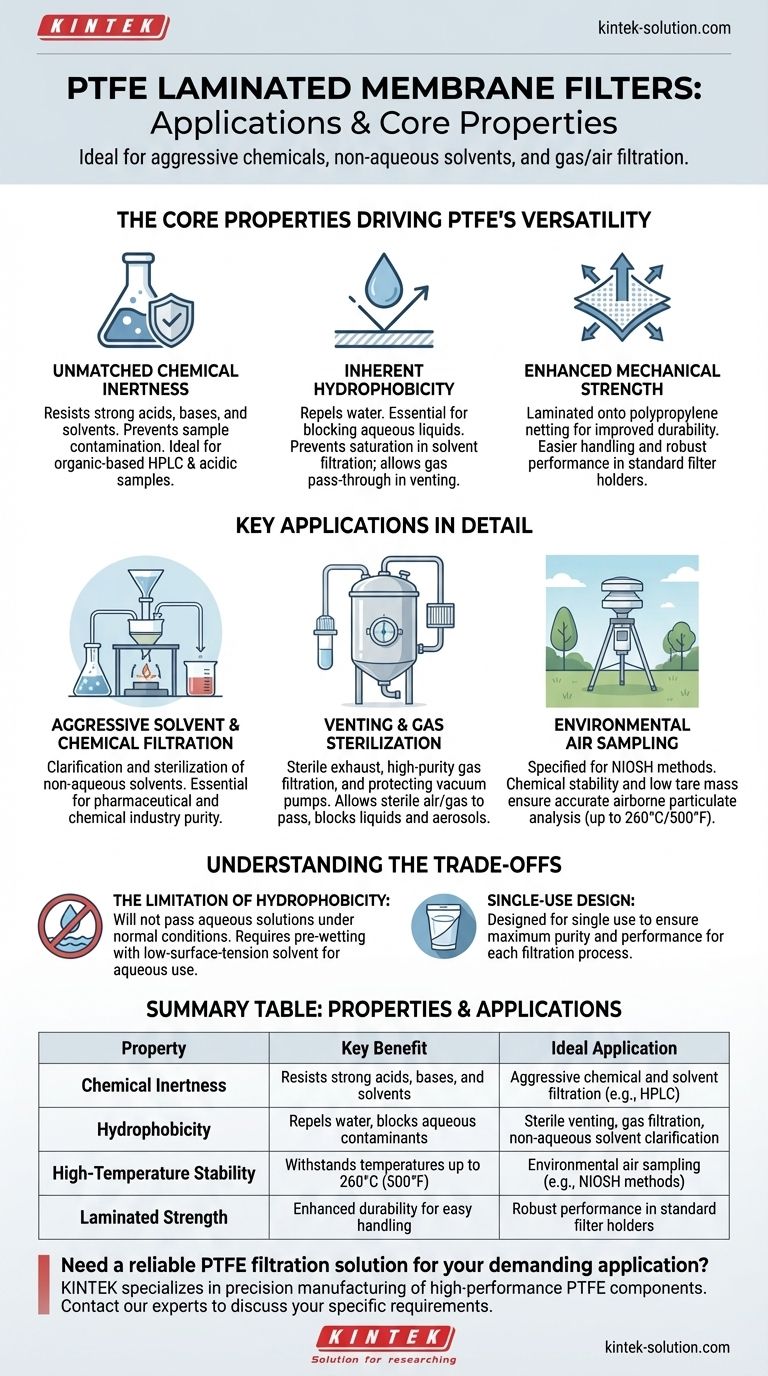

The Core Properties Driving PTFE's Versatility

To understand where PTFE filters excel, we must first look at their fundamental material characteristics. These properties directly translate into their most common and critical applications.

Unmatched Chemical Inertness

A key feature of PTFE is that it is chemically inert. This means it can withstand exposure to a vast range of aggressive chemicals, including strong acids, bases, and solvents, without degrading or corroding.

This inertness ensures that the filter itself does not contaminate the sample, making it ideal for high-purity applications like organic-based HPLC and the filtration of highly acidic samples.

Inherent Hydrophobicity

PTFE is naturally hydrophobic, meaning it repels water. This property is crucial for applications where the passage of water must be prevented.

When filtering non-aqueous solvents, this prevents the filter from becoming saturated with absorbed water from the air. In venting, it allows gas to pass through freely while blocking aqueous aerosols or droplets.

Enhanced Mechanical Strength

These filters are often laminated onto a polypropylene support netting. This lamination significantly improves the membrane's strength and handling characteristics.

The added durability makes the filters easier to work with and more robust for use in most standard disc filter holders without tearing or breaking.

Key Applications in Detail

The unique properties of PTFE make it highly effective for a specific set of demanding filtration tasks across scientific and industrial settings.

Aggressive Solvent and Chemical Filtration

Due to their broad chemical compatibility, PTFE filters are a primary choice for the clarification and sterilization of non-aqueous solvents. They are used extensively in chemical and pharmaceutical industries where sample purity is paramount.

Venting and Gas Sterilization

The hydrophobic nature of PTFE is ideal for venting applications. This includes sterile exhaust for fermentation tanks, high-purity gas filtration, and protecting vacuum pumps from moisture.

The membrane allows sterile air and gas to pass through while acting as a barrier to liquid and aerosolized contaminants.

Environmental Air Sampling

PTFE filters are specified for environmental air sampling, such as in NIOSH methods, for several reasons. Their chemical stability prevents interference with chemical determinations.

Furthermore, their low tare mass and ability to withstand high temperatures (up to 500°F / 260°C) ensure accurate and reliable analysis of airborne particulates.

Understanding the Trade-offs

While incredibly versatile, PTFE filters are not a universal solution. Understanding their primary limitation is critical for proper application.

The Limitation of Hydrophobicity

The single most important limitation is that PTFE filters will not allow aqueous solutions to pass through under normal conditions. Their water-repelling nature prevents water-based liquids from wetting the membrane pores.

To filter an aqueous solution with a PTFE membrane, it must first be pre-wetted with a low-surface-tension solvent like methanol or isopropanol. This is a critical extra step that is not required for hydrophilic membranes.

Single-Use Design

PTFE filters are typically designed for single use. This ensures maximum purity and performance for each filtration but should be factored into the cost and workflow of any process.

Making the Right Choice for Your Goal

Selecting the correct filter requires matching its properties to your specific objective.

- If your primary focus is filtering aggressive organic solvents, acids, or bases: PTFE's unmatched chemical inertness makes it the safest and most reliable choice to ensure sample purity.

- If your primary focus is sterile venting or gas filtration: PTFE's hydrophobicity is essential, as it allows gas to pass freely while effectively blocking moisture and aqueous contaminants.

- If your primary focus is high-purity air sampling: PTFE's combination of chemical stability and low tare mass provides the interference-free results needed for accurate analysis.

Understanding these core principles allows you to select PTFE filters with confidence for your most demanding applications.

Summary Table:

| Property | Key Benefit | Ideal Application |

|---|---|---|

| Chemical Inertness | Resists strong acids, bases, and solvents | Aggressive chemical and solvent filtration (e.g., HPLC) |

| Hydrophobicity | Repels water, blocks aqueous contaminants | Sterile venting, gas filtration, non-aqueous solvent clarification |

| High-Temperature Stability | Withstands temperatures up to 260°C (500°F) | Environmental air sampling (e.g., NIOSH methods) |

| Laminated Strength | Enhanced durability for easy handling | Robust performance in standard filter holders |

Need a reliable PTFE filtration solution for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including laminated membrane filters, seals, liners, and custom labware. Whether you're in the semiconductor, pharmaceutical, medical, or industrial sector, our expertise ensures your filters meet the highest standards of chemical resistance and purity.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact specifications your process requires.

Contact our experts today to discuss how our PTFE solutions can enhance your filtration processes and protect your critical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE with fillers over pure PTFE? Unlock Superior Mechanical Performance

- How do molybdenum disulfide fillers improve PTFE? Enhance Wear Resistance and Lubricity

- What is PTFE and what makes it versatile? The Ultimate High-Performance Polymer

- Why is flow regulation important in control systems? Ensure Stability, Safety, and Efficiency

- What is creep and how does it affect PTFE? Ensure Long-Term Reliability for Your Components

- How does PTFE contribute to semiconductor manufacturing? Ensure Purity and Prevent Contamination

- What services are offered to guide customers in the design and production stages of PTFE coatings? Get Expert Consultancy for Optimal Performance

- Which PTFE formulations are suitable for the energy sector? Achieve Superior Performance in Extreme Conditions