In simple terms, creep is the tendency of a solid material to deform permanently over time when subjected to a constant load or stress. For Polytetrafluoroethylene (PTFE), this means that even under a steady force well below its breaking point, a component like a seal or washer will slowly flatten or change shape. This effect is significantly accelerated at higher temperatures.

The core issue with PTFE is that its molecular structure, which provides excellent low-friction and chemical resistance, lacks the "memory" to spring back from sustained pressure. To achieve mechanical stability in load-bearing applications, you must use either a filled grade of PTFE or a structurally reinforced design.

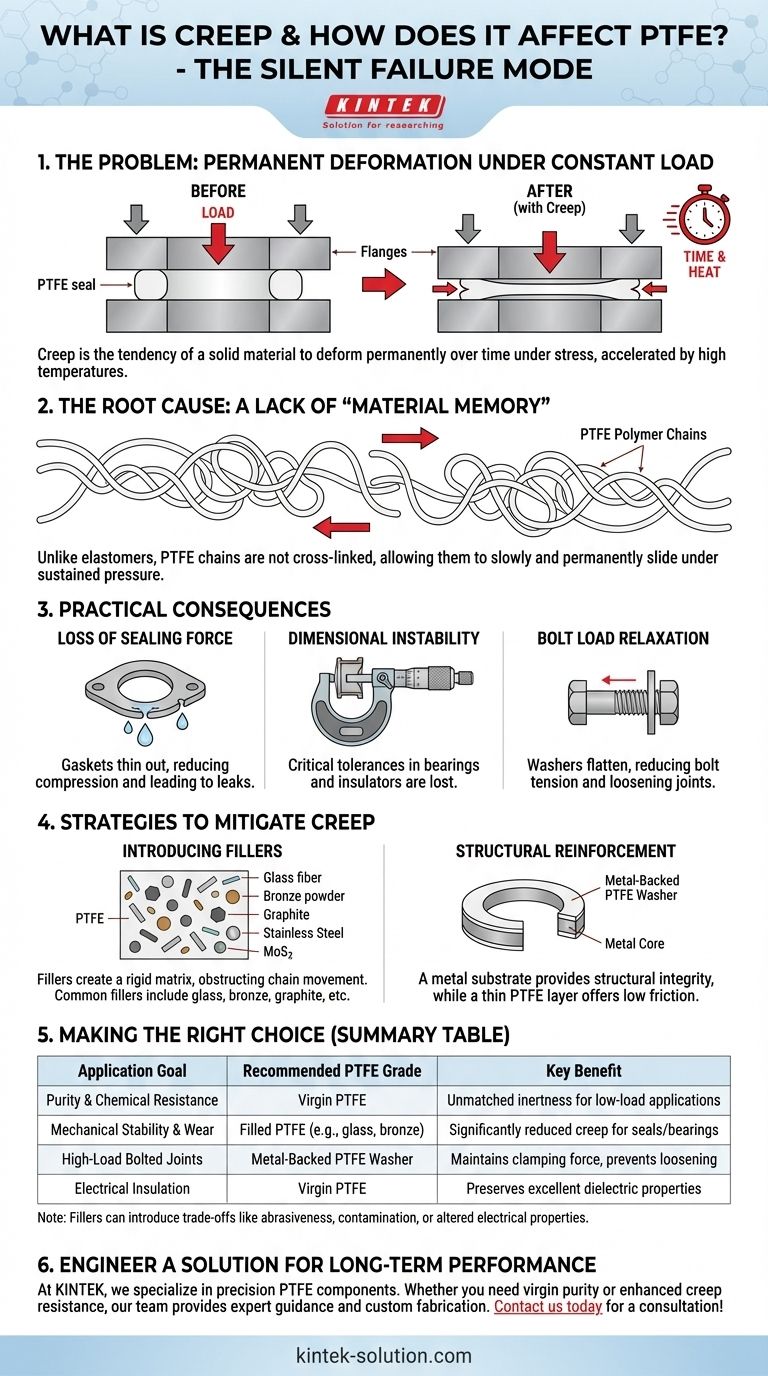

The Fundamental Cause of Creep in PTFE

A Lack of "Material Memory"

Unlike elastomers like rubber, which have cross-linked polymer chains that snap back into place after being compressed, PTFE's molecular structure is different. Its long polymer chains are not chemically bonded to each other.

Under sustained pressure, these chains can slowly and permanently slide past one another. This molecular slippage is the physical mechanism of creep. Because there are no cross-links to pull the chains back to their original position, the deformation is permanent.

The Influence of Temperature and Pressure

Heat provides energy to the polymer chains, making it easier for them to move and slide. Therefore, creep in PTFE becomes much more pronounced as temperatures rise, even if the pressure remains constant.

Constant pressure provides the steady, external force that drives this slow deformation over time.

Practical Consequences of PTFE Creep

Loss of Sealing Force

This is the most common failure mode in gasket and seal applications. A PTFE gasket compressed between two flanges will creep over time, reducing its thickness and the compressive sealing force. This can eventually lead to leaks.

Dimensional Instability

For precision components like bearings, bushings, or insulators, creep can cause a loss of critical tolerances. This change in dimension can negatively impact the performance and reliability of the entire assembly.

Bolt Load Relaxation

When a PTFE washer is used in a bolted joint, its tendency to creep will cause the washer to thin out. This reduces the tension in the bolt, potentially causing the entire connection to loosen over time.

Strategies to Mitigate PTFE Creep

Introducing Fillers

To combat creep, manufacturers blend virgin PTFE with various reinforcing fillers. These fillers create a rigid internal matrix that physically obstructs the movement of the PTFE polymer chains.

Common fillers include glass, bronze, graphite, stainless steel, and molybdenum disulfide. Each provides a different balance of properties, such as improved wear resistance or thermal conductivity, in addition to reducing creep.

Structural Reinforcement

For extremely high-load applications, the best solution is often structural reinforcement. A common example is a metal-backed PTFE washer.

In this design, a sturdy metal washer provides the structural integrity and load-bearing capability, while a thin layer of PTFE on the surface provides the desired low-friction or chemically-resistant interface.

Understanding the Trade-offs

The Downsides of Fillers

While fillers significantly improve creep resistance, they are not a universal solution. They introduce critical trade-offs that must be considered.

- Abrasiveness: Glass and bronze fillers can be abrasive to softer mating surfaces, such as aluminum or other plastics.

- Contamination: Graphite or MoS2 can shed particles, making them unsuitable for clean environments like food processing or semiconductor manufacturing.

- Altered Electrical Properties: Fillers like graphite, carbon, or bronze are conductive and will severely degrade PTFE's excellent dielectric strength, making them unusable for electrical insulation.

The Limits of Virgin PTFE

Virgin PTFE remains the best choice for its purity, chemical inertness, and electrical insulation properties. However, it should only be used in applications where static, compressive loads are low and predictable.

Making the Right Choice for Your Application

- If your primary focus is purity and chemical resistance: Use virgin PTFE, but only in applications where sustained mechanical loads are minimal.

- If your primary focus is mechanical stability and wear resistance: Choose a filled PTFE like glass- or bronze-filled, but ensure it is not abrasive to your mating components.

- If your primary focus is preventing bolt loosening in a high-load joint: A metal-backed PTFE washer is the most reliable choice to maintain clamping force.

- If your primary focus is high-performance electrical insulation: You must use virgin PTFE, as nearly all common fillers will compromise its dielectric properties.

By understanding the relationship between PTFE's structure and its tendency to creep, you can select the precise material grade that ensures long-term reliability for your design.

Summary Table:

| Application Goal | Recommended PTFE Grade | Key Benefit |

|---|---|---|

| Purity & Chemical Resistance | Virgin PTFE | Unmatched inertness, ideal for low-load applications |

| Mechanical Stability & Wear Resistance | Filled PTFE (e.g., glass, bronze) | Significantly reduced creep for seals and bearings |

| High-Load Bolted Joints | Metal-Backed PTFE Washer | Maintains clamping force, prevents loosening |

| Electrical Insulation | Virgin PTFE | Preserves excellent dielectric properties |

Need a PTFE component that won't fail under pressure?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand that creep resistance is critical for your application's reliability. Whether you need the purity of virgin PTFE or the enhanced mechanical properties of a filled grade, our team provides expert guidance and custom fabrication from prototypes to high-volume orders.

Let's engineer a solution that ensures long-term performance. Contact us today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are PTFE and Teflon, and why are they important? Unlock the Power of High-Performance Polymers

- How does PTFE perform when exposed to sulfuric acid? Unmatched Chemical Resistance for Demanding Applications

- What are the key applications enabled by PTFE's properties? Solve Extreme Mechanical, Chemical & Electrical Challenges

- What are the key characteristics of PTFE? A Guide to Its Extreme Performance

- What makes PTFE valuable for electrical applications? Unlocking Superior Insulation and Signal Integrity

- What is modified PTFE and how does it differ from standard PTFE? A Guide to Enhanced Performance

- What role does PTFE play in automotive manufacturing? Enhancing Vehicle Durability and Efficiency

- What industrial applications utilize expanded PTFE? Sealing, Filtration & Insulation Solutions