In any automated process, flow regulation is the primary mechanism for maintaining stability, efficiency, and safety. It ensures that a fluid or gas moves through a system at a precise, intended rate, preventing the chaotic and often dangerous outcomes that result from uncontrolled conditions. Without it, achieving a desired temperature, pressure, or chemical reaction becomes nearly impossible.

Flow is a fundamental process variable that directly influences almost every other variable in a system. Regulating it is not just about controlling movement; it is about establishing the predictable foundation required to control an entire process from start to finish.

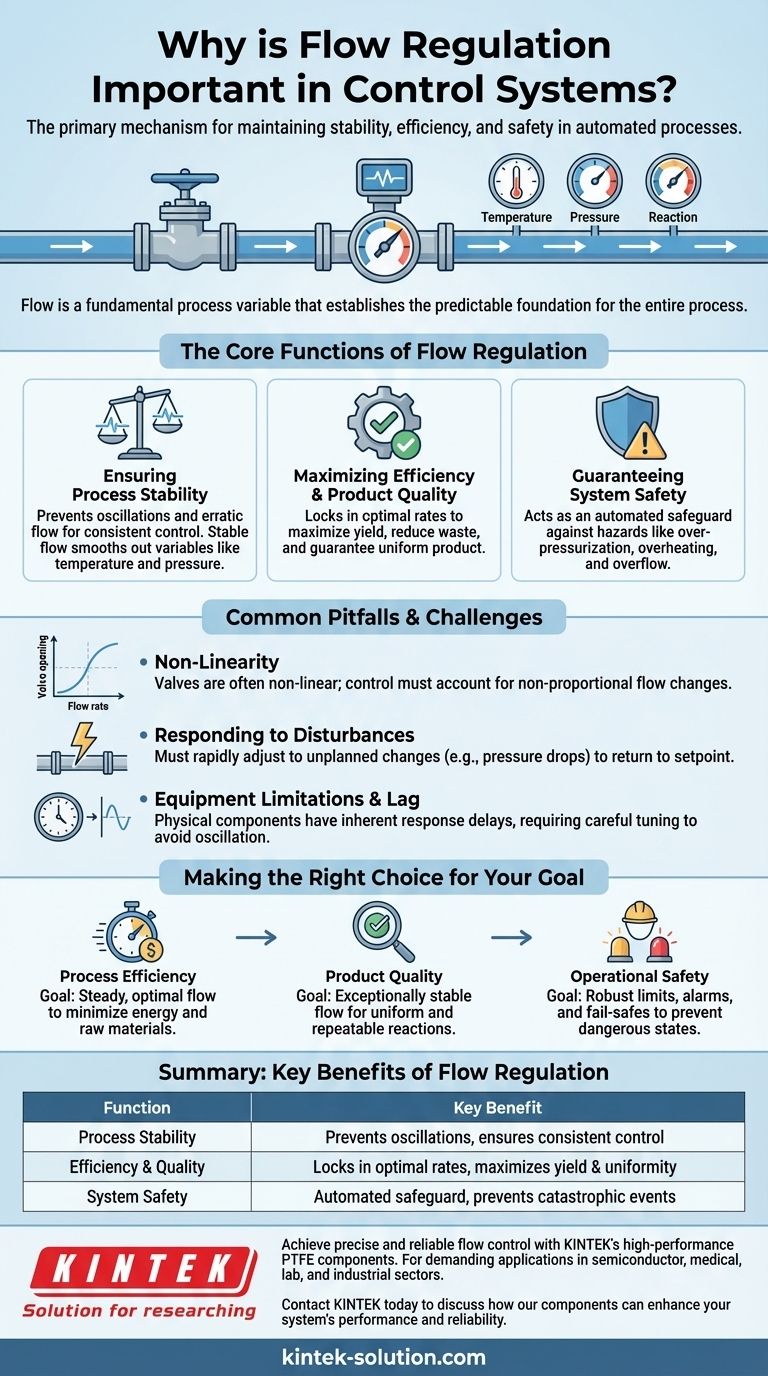

The Core Functions of Flow Regulation

At its heart, a control system's job is to keep a process variable (like temperature or pressure) as close as possible to a desired setpoint. Flow is often the tool used to achieve this, making its precise regulation essential.

Ensuring Process Stability

Erratic or unregulated flow is a direct cause of instability. Imagine trying to maintain a specific water temperature in a tank by adding hot water from a hose that sputters unpredictably. The tank's temperature would constantly overshoot and undershoot your target.

In an industrial context, this oscillation can disrupt chemical reactions, lead to inconsistent product quality, and cause other control loops in the system (like pressure or level controllers) to become unstable as they try to compensate. Stable flow smooths out these variables.

Maximizing Efficiency and Product Quality

Every process is designed to run at an optimal point for peak efficiency. For example, a chemical reactor may produce the highest yield of a product only when reactants are introduced at a very specific, constant rate.

Deviations from this rate—even small ones—can waste expensive raw materials, consume excess energy (e.g., pumps working harder than necessary), and result in a final product that fails to meet quality specifications. Precise flow regulation locks in the process at its most productive and cost-effective state.

Guaranteeing System Safety

This is the most critical function of flow regulation. Uncontrolled flow can lead directly to hazardous conditions, such as the over-pressurization of a vessel, the overheating of a reactor, or the overflow of a tank.

Control systems use flow regulation to enforce safety limits. If a pressure sensor detects a dangerous increase, the flow control loop can immediately reduce or stop the inflow of material, acting as an automated safeguard to prevent equipment failure or a catastrophic event.

Common Pitfalls and Challenges

Achieving perfect flow regulation is not a simple task. The physical realities of equipment and processes introduce challenges that a control system must be designed to overcome.

The Problem of Non-Linearity

Many control elements, especially valves, are non-linear. This means that opening a valve by 50% does not necessarily result in 50% of the maximum flow. The actual flow rate might change very little at the beginning of the valve's travel and then change dramatically near the end.

A robust control strategy must account for this non-linear behavior to avoid over- or under-reacting as it adjusts the flow rate.

Responding to System Disturbances

A disturbance is any unplanned event that pushes a process away from its setpoint. This could be a sudden change in upstream pressure, a fluctuation in ambient temperature, or a change in demand downstream.

A key purpose of a flow control loop is to detect these disturbances and rapidly adjust the flow to counteract their effect, bringing the process variable back to its setpoint with minimal deviation. Failure to do so negates the purpose of the control system.

Equipment Limitations and Lag

Physical components do not respond instantly. A valve takes time to move, and a sensor takes time to register a change. This inherent process lag can make control difficult.

If a control system is not tuned correctly to account for this lag, it can lead to oscillation, where the controller is constantly chasing a setpoint it can never quite catch.

Making the Right Choice for Your Goal

The way you approach flow regulation depends on your highest priority for the system.

- If your primary focus is process efficiency: Your goal is to maintain a steady, optimal flow rate that minimizes the use of energy and raw materials.

- If your primary focus is product quality: You must prioritize exceptionally stable flow to ensure all reactions and processes are uniform and repeatable.

- If your primary focus is operational safety: Your system must include robust flow limits, alarms, and automated fail-safes to prevent conditions from ever reaching a dangerous state.

Ultimately, mastering flow regulation is the key to transforming an unpredictable process into a controlled, reliable, and safe operation.

Summary Table:

| Function | Key Benefit |

|---|---|

| Process Stability | Prevents oscillations and ensures consistent control of temperature, pressure, and reactions. |

| Efficiency & Quality | Locks in optimal rates to maximize yield, reduce waste, and guarantee product uniformity. |

| System Safety | Acts as an automated safeguard to prevent over-pressurization, overheating, and catastrophic events. |

Achieve precise and reliable flow control in your systems with KINTEK's high-performance PTFE components.

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, consistent flow is non-negotiable. KINTEK specializes in manufacturing custom PTFE seals, liners, and labware that offer exceptional chemical resistance and durability, ensuring long-term reliability in your most critical control loops.

Whether you need prototypes or high-volume orders, our precision manufacturing and custom fabrication services help you maintain the stable flows required for peak efficiency, superior product quality, and uncompromising safety.

Contact KINTEK today to discuss how our components can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the advantages of hydrophobic PTFE membrane filters? Achieve Unmatched Chemical Resistance & Purity

- How do graphite fillers enhance PTFE? Achieve Superior Self-Lubrication and Wear Resistance

- What is PTFE's resistance to hydrochloric acid at different concentrations? Discover Unmatched Chemical Inertness

- What are the two common forms in which PTFE is available? Raw Resins vs. Semi-Finished Shapes

- What are the key properties of PTFE material? A Guide to Extreme Performance

- What are the key features of PTFE laminated membrane filters? Hydrophobic, Chemically Inert, and Durable

- What is the thermal stability range of PTFE? From -200°C to 260°C, but understand the critical limits.

- What is virgin (unfilled) grade PTFE used for? Essential Applications for Ultimate Purity