The primary service offered is expert consultancy to guide you through the design and production stages of applying PTFE coatings. This guidance is specifically tailored to ensure the unique attributes of PTFE—such as low friction, chemical inertness, and non-stick properties—are fully maximized for your specific application.

The core challenge isn't just applying a PTFE coating; it's engineering a complete surface solution. Expert consultancy bridges the gap between the material's potential and its actual performance on your component.

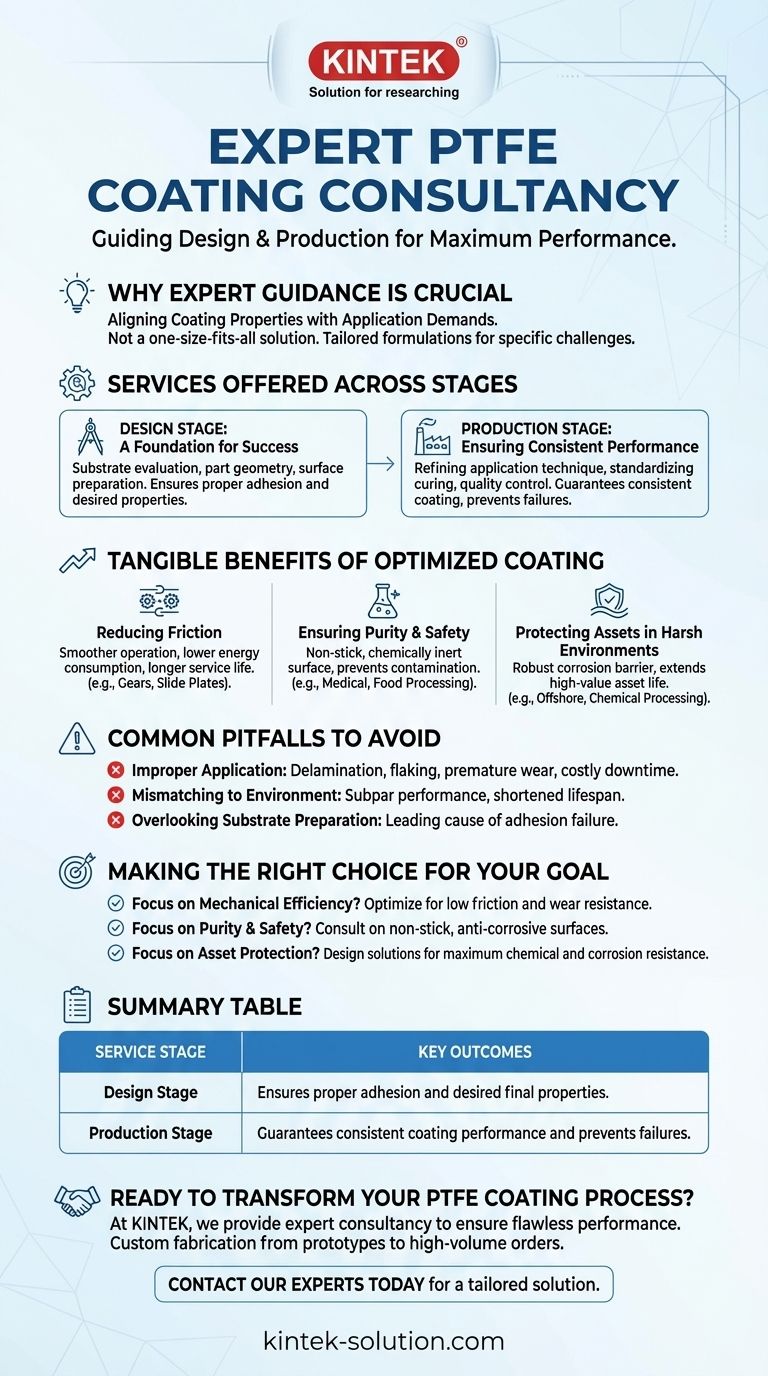

Why Expert Guidance is Crucial for PTFE Coatings

Polytetrafluoroethylene (PTFE) is a high-performance material, but its effectiveness is entirely dependent on how it's integrated into a product's design and manufacturing process.

Aligning Coating Properties with Application Demands

PTFE coatings are not a one-size-fits-all solution. The optimal formulation and application process for a non-stick surface in the food industry is vastly different from one designed for corrosion resistance in a chemical processing plant.

Expert guidance ensures the chosen coating system directly addresses the specific challenges of your environment, whether it's reducing friction in automotive gears or preventing contamination in medical tubing.

The Design Stage: A Foundation for Success

Consultancy during the design phase focuses on critical factors beyond simple material selection. This includes evaluating the substrate material, the geometry of the part, and the required surface preparation.

Making the right decisions at this stage is essential for ensuring proper adhesion and achieving the desired final properties of the coating.

The Production Stage: Ensuring Consistent Performance

Guidance extends into the production workflow. This involves refining the application technique, standardizing curing protocols, and implementing quality control checks.

Proper production oversight guarantees that every component is coated consistently, delivering reliable performance and preventing premature failures.

The Tangible Benefits of an Optimized Coating

When design and production are guided by expertise, the attributes of PTFE translate into measurable advantages across industries.

Reducing Friction in Mechanical Systems

For components like gears and slide plates, an expertly applied coating dramatically reduces the coefficient of friction. This leads to smoother operation, lower energy consumption, and a longer service life for mechanical parts.

Ensuring Purity and Safety

In medical, laboratory, and food processing applications, the right PTFE coating provides a non-stick, chemically inert surface. This prevents microbial contamination and ensures fluids flow smoothly without residue, which is critical for safety and product integrity.

Protecting Assets in Harsh Environments

For equipment used in offshore operations or chemical processing, a properly engineered PTFE coating acts as a robust barrier against corrosion. This protection is vital for extending the life of high-value assets operating in challenging conditions.

Common Pitfalls to Avoid

Without specialized knowledge, companies often face challenges that undermine the value of the coating investment.

The Risk of Improper Application

A poorly applied PTFE coating can easily delaminate, flake, or wear away prematurely. This failure not only negates the benefit of the coating but can also lead to costly equipment downtime and product recalls.

Mismatching the Coating to the Environment

Choosing a standard PTFE formulation without considering the specific chemical, thermal, and mechanical stresses of the application is a frequent mistake. This results in subpar performance and a shortened component lifespan.

Overlooking Substrate Preparation

The success of any coating is highly dependent on the condition of the surface it is applied to. Insufficient or incorrect substrate preparation is a leading cause of coating adhesion failure, a problem that expert guidance helps prevent.

Making the Right Choice for Your Goal

Engaging with a consultancy service allows you to tailor the PTFE solution to your most critical performance indicator.

- If your primary focus is mechanical efficiency: Seek guidance to optimize for low friction and wear resistance on components like gears and slide plates.

- If your primary focus is product purity and safety: Consult on the correct material selection and application for non-stick, anti-corrosive surfaces in food, medical, or lab settings.

- If your primary focus is asset protection: Engage experts to design a coating solution that provides maximum chemical and corrosion resistance for industrial equipment.

Ultimately, partnering with technical experts transforms a simple coating process into a strategic enhancement of your product's performance and reliability.

Summary Table:

| Service Stage | Key Focus Areas | Key Outcomes |

|---|---|---|

| Design Stage | Substrate evaluation, part geometry, surface preparation | Ensures proper adhesion and desired final properties |

| Production Stage | Application technique, curing protocols, quality control | Guarantees consistent coating performance and prevents failures |

Ready to transform your PTFE coating process into a strategic advantage?

At KINTEK, we don't just supply high-quality PTFE components—we provide the expert consultancy to ensure they perform flawlessly. Our guidance bridges the gap between PTFE's potential and your product's real-world demands, whether you're in the semiconductor, medical, laboratory, or industrial sectors.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring precision and reliability. Let us help you maximize low friction, chemical resistance, and non-stick properties for your specific application.

Contact our experts today for a tailored solution that enhances performance, extends product life, and protects your assets.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability