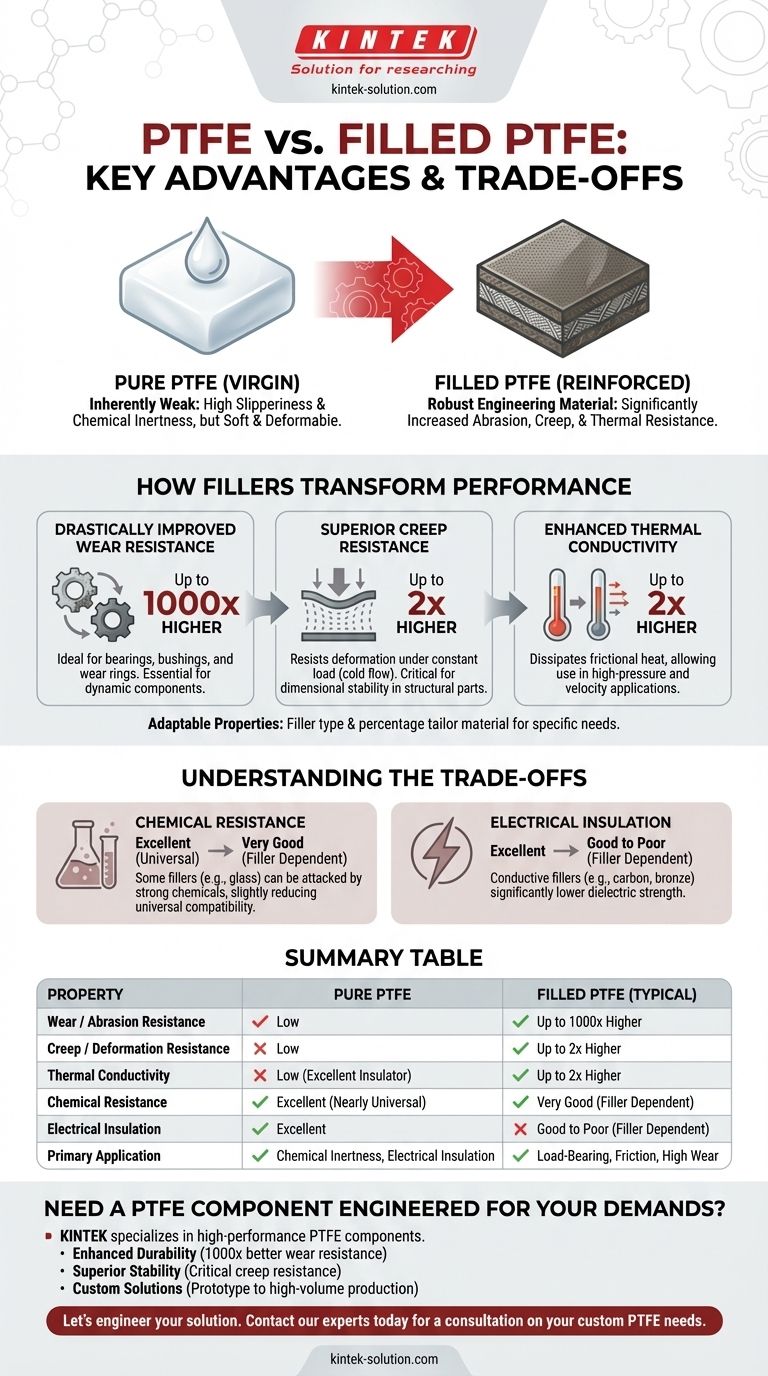

The primary advantage of adding fillers to Polytetrafluoroethylene (PTFE) is to dramatically improve its mechanical properties where the pure material is inherently weak. While pure PTFE is exceptionally slick and chemically resistant, it is also mechanically soft. Fillers transform it into a robust engineering material by significantly increasing its resistance to abrasion and deformation under load (creep).

While pure PTFE offers unmatched slipperiness and chemical inertness, it often fails in demanding mechanical roles. Adding fillers is the essential engineering step that elevates PTFE from a versatile polymer to a high-performance material capable of withstanding significant physical stress, friction, and heat.

The Core Weaknesses of Pure PTFE

To understand the value of fillers, we must first recognize the inherent limitations of pure, or "virgin," PTFE. Its unique qualities come with significant mechanical drawbacks.

Insufficient Abrasion Resistance

Pure PTFE is relatively soft and can wear away quickly in applications involving friction or abrasive contact. This limits its lifespan in dynamic components like seals or bearings.

High Deformation Under Load (Creep)

When subjected to a constant load, especially at elevated temperatures, pure PTFE will slowly deform or "cold flow." This phenomenon, known as creep, makes it unsuitable for structural or load-bearing parts where dimensional stability is critical.

Poor Thermal Conductivity

PTFE is an excellent thermal insulator. In high-speed, high-friction applications, this prevents heat from dissipating, which can lead to premature failure of the component.

How Fillers Transform PTFE's Performance

Fillers are not just additives; they are a reinforcing matrix within the PTFE, fundamentally changing its behavior under stress and creating what is often called Reinforced PTFE (RPTFE).

Drastically Improved Wear Resistance

The most significant enhancement is in wear and abrasion resistance. Adding fillers can make the resulting compound up to 1000 times more resistant to abrasion than pure PTFE, making it ideal for bearings, bushings, and wear rings.

Superior Creep Resistance

Fillers provide a rigid structure that helps the material resist deformation. Filled PTFE can offer up to twice the creep resistance of its pure counterpart, enabling its use in valves, gaskets, and components under constant compression.

Enhanced Thermal Conductivity

Certain fillers, like bronze or carbon, improve the material's ability to transfer heat. A filled compound can have twice the thermal conductivity, allowing it to dissipate frictional heat and maintain its integrity at higher pressures and velocities (PV).

Adaptable Properties

The type and percentage of filler can be precisely selected to tailor the material's characteristics. This allows for an adaptable coefficient of friction, versatile electrical properties, and other custom features for specific applications.

Understanding the Trade-offs

Introducing fillers is an engineering compromise. While you gain significant mechanical strength, you may alter some of PTFE's other well-known properties.

Impact on Chemical Resistance

Pure PTFE is famously inert to nearly all chemicals. Some fillers, particularly glass, can be attacked by strong alkalis or hydrofluoric acid, slightly reducing the compound's universal chemical compatibility.

Effect on Electrical Insulation

Pure PTFE is an outstanding electrical insulator. However, adding conductive fillers like carbon or bronze will dramatically lower its dielectric strength, making it unsuitable for high-voltage insulating applications.

Modification of Friction

While the coefficient of friction for filled PTFE remains very low, it is generally slightly higher than that of pure PTFE. The filler material directly influences the final frictional characteristics.

Making the Right Choice for Your Application

Selecting between pure and filled PTFE depends entirely on the operational demands of the component.

- If your primary focus is maximum chemical inertness or electrical insulation: Pure PTFE is the superior choice, provided mechanical loads and frictional wear are minimal.

- If your application involves load-bearing, friction, or high speeds: A filled PTFE compound is almost always necessary to prevent premature failure from wear or creep.

- If you need to dissipate heat from a contact surface: Select a filled PTFE with a thermally conductive filler like bronze, carbon, or graphite.

By understanding the role of fillers, you can specify a material precisely engineered to meet your specific mechanical and thermal demands.

Summary Table:

| Property | Pure PTFE | Filled PTFE (Typical) |

|---|---|---|

| Wear / Abrasion Resistance | Low | Up to 1000x Higher |

| Creep / Deformation Resistance | Low | Up to 2x Higher |

| Thermal Conductivity | Low (Excellent Insulator) | Up to 2x Higher |

| Chemical Resistance | Excellent (Nearly Universal) | Very Good (Filler Dependent) |

| Electrical Insulation | Excellent | Good to Poor (Filler Dependent) |

| Primary Application | Chemical Inertness, Electrical Insulation | Load-Bearing, Friction, High Wear |

Need a PTFE Component Engineered for Your Demands?

KINTEK specializes in manufacturing high-performance PTFE components—from custom seals and liners to specialized labware—precisely engineered with the right filler compounds to solve your specific challenges.

We serve the semiconductor, medical, laboratory, and industrial sectors by delivering:

- Enhanced Durability: Components with up to 1000x better wear resistance for longer service life.

- Superior Stability: Critical creep resistance to maintain dimensional integrity under load.

- Custom Solutions: Prototype to high-volume production tailored to your mechanical, thermal, and chemical requirements.

Let's engineer your solution. Contact our experts today for a consultation on your custom PTFE needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F