For applications in the energy sector, the most suitable Polytetrafluoroethylene (PTFE) formulations are those filled with carbon or graphite. These specific grades enhance the material's inherent properties, offering superior thermal conductivity and improved friction characteristics essential for resilience in high-temperature and high-wear environments.

The energy industry demands materials that can withstand extreme operational stress without failure. While standard PTFE offers excellent chemical resistance and low friction, incorporating carbon or graphite fillers transforms it into a high-performance material with the enhanced thermal stability and wear resistance required for critical applications.

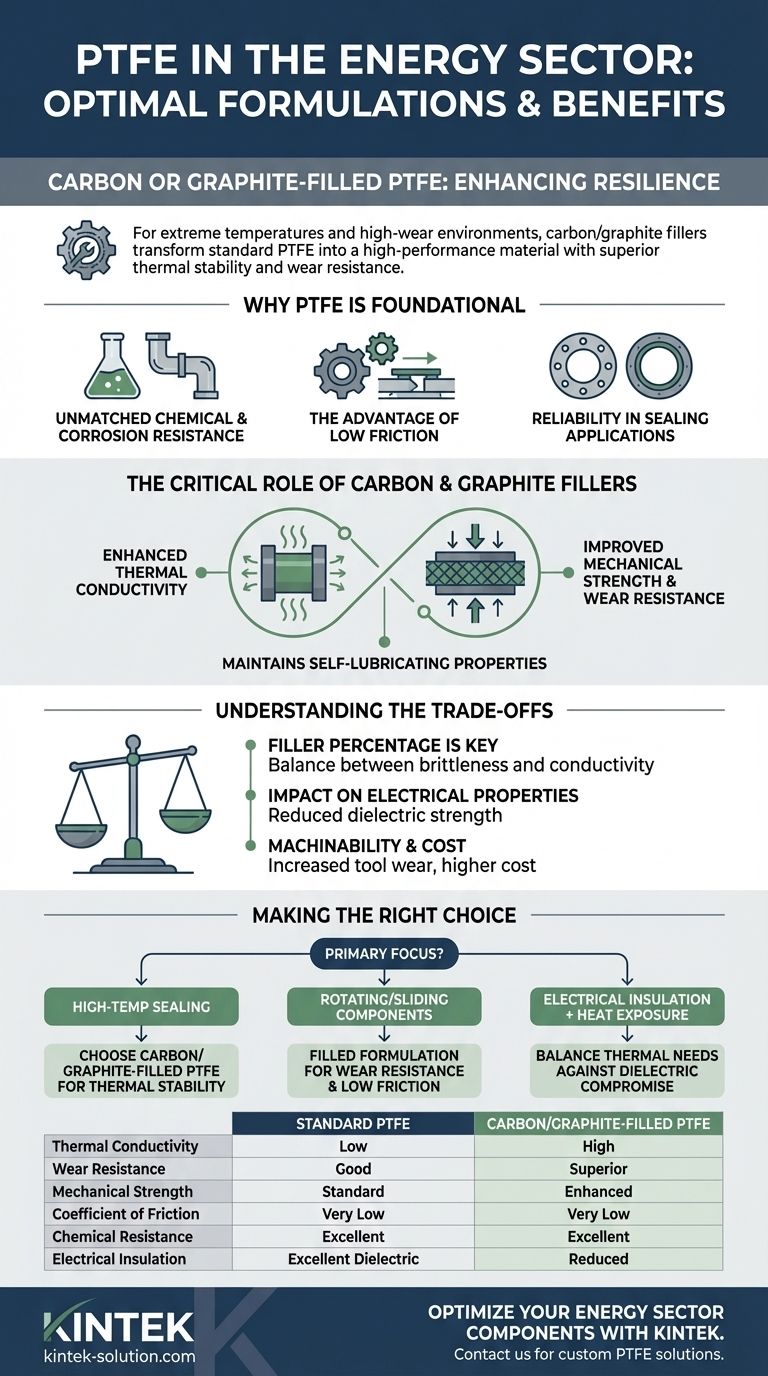

Why PTFE is a Foundational Material in Energy

Before examining specific formulations, it's crucial to understand why PTFE is so widely used in demanding industrial environments. Its fundamental properties provide a powerful baseline for performance.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert to most industrial chemicals and corrosive agents. This makes it an ideal choice for seals, gaskets, and linings in equipment that handles aggressive fluids, a common scenario in oil and gas extraction and processing.

The Advantage of Low Friction

The material possesses one of the lowest coefficients of friction of any solid. In mechanisms with rotating or sliding parts, such as bearings or valve seats, this property dramatically reduces wear and tear, lowers energy consumption, and extends the operational life of components.

Reliability in Sealing Applications

PTFE's conformability and resilience make it an exceptional sealing material. It prevents leaks under high pressure and across a wide temperature range, ensuring both operational efficiency and safety.

The Critical Role of Carbon and Graphite Fillers

While virgin PTFE is highly capable, its performance under high mechanical loads and temperatures is limited. Fillers are added to overcome these limitations.

Enhancing Thermal Conductivity

Pure PTFE is an excellent thermal insulator, which can be a disadvantage as it can trap heat and degrade in high-temperature applications. Carbon and graphite fillers significantly improve thermal conductivity, allowing the material to dissipate heat away from critical surfaces.

Improving Mechanical Strength and Wear Resistance

The addition of these fillers increases the material's hardness, compressive strength, and overall durability. This reinforcement is vital for components subjected to significant mechanical stress, preventing deformation and premature failure.

Maintaining Self-Lubricating Properties

Crucially, adding carbon or graphite does not compromise the low-friction nature of PTFE. The resulting composite material retains its self-lubricating qualities while gaining the mechanical and thermal benefits of the filler.

Understanding the Trade-offs and Considerations

Selecting a filled PTFE is not without its nuances. An objective assessment requires acknowledging the trade-offs involved.

Filler Percentage is Key

The concentration of the filler directly impacts the final properties. A higher percentage of carbon might maximize thermal conductivity but could also increase brittleness. This balance must be tailored to the specific application's demands.

Impact on Electrical Properties

Virgin PTFE is an outstanding electrical insulator (a dielectric). Because carbon and graphite are electrically conductive, adding them as a filler will reduce the material's dielectric strength. This is a critical consideration for any application requiring electrical insulation.

Machinability and Cost

While PTFE is known for being easy to machine, filled grades are more abrasive than their unfilled counterparts. This can lead to increased tool wear during fabrication. Filled grades are also typically more expensive, reflecting the cost of the additives and processing.

Making the Right Choice for Your Application

Your choice of PTFE formulation should be dictated by the specific operational demands of the component.

- If your primary focus is high-temperature sealing: Choose a carbon or graphite-filled PTFE to ensure superior thermal stability and prevent material degradation under heat.

- If your primary focus is on rotating or sliding components: A filled formulation is critical for its superior wear resistance and low friction, which extends the service life of bearings, rings, and seals.

- If your primary focus is electrical insulation with some heat exposure: You must carefully balance the need for thermal conductivity from fillers against the potential compromise of the material's insulating properties.

Ultimately, selecting the correct filled PTFE formulation is a strategic engineering decision that directly enhances operational reliability and longevity in the demanding energy sector.

Summary Table:

| Property | Standard PTFE | Carbon/Graphite-Filled PTFE |

|---|---|---|

| Thermal Conductivity | Low (Insulator) | High (Improved Heat Dissipation) |

| Wear Resistance | Good | Superior |

| Mechanical Strength | Standard | Enhanced (Harder, Higher Compressive Strength) |

| Coefficient of Friction | Very Low | Very Low (Self-Lubricating) |

| Chemical Resistance | Excellent | Excellent |

| Electrical Insulation | Excellent Dielectric | Reduced (Conductive Fillers) |

Optimize your energy sector components with high-performance PTFE from KINTEK.

Facing extreme temperatures, high wear, or corrosive environments? KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact carbon or graphite-filled PTFE formulation your application demands for maximum reliability and longevity.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems