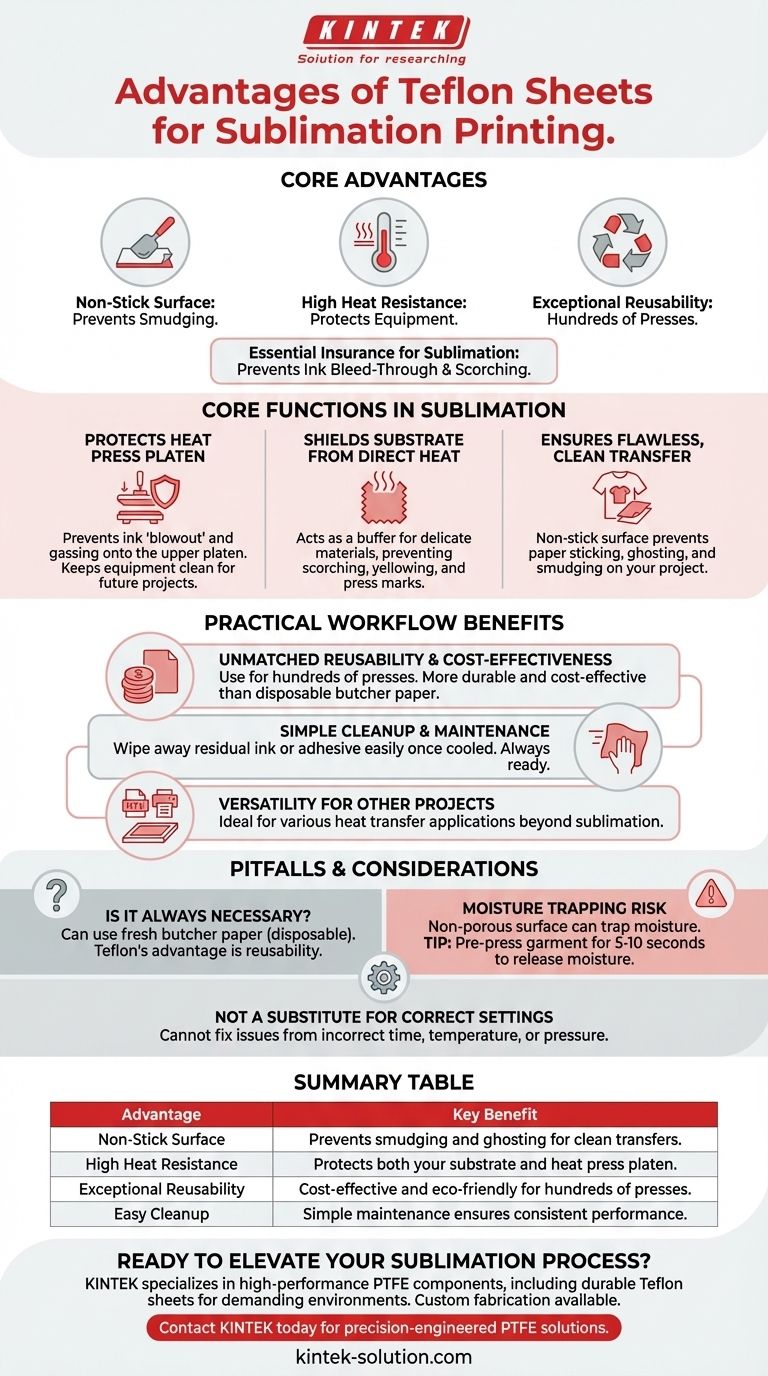

At its core, a Teflon sheet provides three critical advantages for sublimation printing: a non-stick surface, high heat resistance, and exceptional reusability. These features work together to protect both your heat press and your product, ensuring clean, consistent, and professional-quality transfers every time.

A Teflon sheet acts as an essential insurance policy for your sublimation process. It creates a protective barrier that prevents ink bleed-through and scorching, safeguarding your equipment and ensuring your final prints are vibrant and free of defects.

The Core Functions of a Teflon Sheet in Sublimation

A Teflon sheet is more than just a protective cover; it plays an active role in the quality of the final transfer. Understanding its function reveals why it is a staple for both hobbyists and professionals.

It Protects Your Heat Press Platen

The upper platen of your heat press is a critical component. A Teflon sheet placed on top of your sublimation paper prevents any ink "blowout" from gassing through the paper and permanently staining the platen.

This keeps your equipment clean and prevents old ink from accidentally transferring onto future projects, which would ruin them.

It Shields Your Substrate from Direct Heat

Many materials, especially delicate polyester fabrics, are susceptible to scorching or yellowing under the high heat required for sublimation.

The Teflon sheet acts as a buffer, distributing the heat more gently and protecting the material from direct contact with the metal platen, which can leave press marks or cause discoloration.

It Ensures a Flawless, Clean Transfer

The non-stick surface is perhaps its most well-known quality. This property prevents the sublimation paper from sticking to your garment or substrate.

More importantly, it ensures that if any part of the design shifts or bleeds, the mess stays on the sheet, not on your project, preventing smudges and "ghosting."

Understanding the Practical Advantages

Beyond the technical process, using a Teflon sheet introduces tangible benefits to your workflow, saving you time, money, and frustration.

Unmatched Reusability and Cost-Effectiveness

Unlike disposable alternatives like butcher paper, a single Teflon sheet can be used for hundreds or even thousands of presses.

This durability makes it an extremely cost-effective tool in the long run and reduces waste, making it a more environmentally friendly option.

Simple Cleanup and Maintenance

Any residual ink or adhesive that gets on the sheet can be wiped away easily once it has cooled. This simple maintenance ensures it's always ready for the next job without any fuss.

Versatility for Other Projects

The properties that make Teflon sheets great for sublimation also make them ideal for other heat transfer applications, such as heat transfer vinyl (HTV), screen print transfers, and other crafting projects.

Common Pitfalls and Considerations

While highly beneficial, it's important to understand the context of using a Teflon sheet to avoid common mistakes. It is a tool, not a replacement for proper technique.

Is It Always Necessary?

You can perform sublimation without a Teflon sheet by using a fresh sheet of uncoated butcher paper for every press. Butcher paper serves a similar protective function but is a single-use, disposable item.

The primary advantage of Teflon is its reusability and superior durability. It is considered an essential tool for anyone doing sublimation regularly.

Potential for Moisture Trapping

One key consideration is that a Teflon sheet's non-porous surface can sometimes trap moisture steaming out of a garment during pressing. This trapped moisture can cause blotchy or faded spots in your transfer.

To prevent this, always pre-press your garment for 5-10 seconds before adding your design. This releases any ambient moisture and ensures a dry surface for a perfect sublimation.

Not a Substitute for Correct Settings

A Teflon sheet cannot fix problems caused by incorrect time, temperature, or pressure. It protects and facilitates the process, but the quality of your print still depends on using the right settings for your specific substrate and equipment.

Making the Right Choice for Your Goal

Your choice of protective cover should align with your priorities for quality, efficiency, and budget.

- If your primary focus is maximum protection and long-term value: A Teflon sheet is the superior choice for its unmatched reusability and durability.

- If your primary focus is avoiding any risk of moisture issues with garments: Use a fresh sheet of high-quality, uncoated butcher paper for each press as a foolproof, disposable alternative.

- If you work with multiple heat transfer methods (like HTV and sublimation): A Teflon sheet offers the most versatility and is an indispensable tool for your workflow.

Ultimately, incorporating the right protective layer into your process gives you the confidence to press perfectly every time.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Non-Stick Surface | Prevents smudging and ghosting for clean transfers. |

| High Heat Resistance | Protects both your substrate and heat press platen. |

| Exceptional Reusability | Cost-effective and eco-friendly for hundreds of presses. |

| Easy Cleanup | Simple maintenance ensures consistent performance. |

Ready to elevate your sublimation process with precision-engineered PTFE sheets?

KINTEK specializes in manufacturing high-performance PTFE components, including durable Teflon sheets ideal for the demanding environments of sublimation printing, industrial applications, and specialized laboratories. Our sheets are designed for superior heat resistance and non-stick performance, ensuring your equipment is protected and your results are consistently professional.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions to your exact specifications.

Contact KINTEK today to discuss your needs and discover how our PTFE solutions can bring reliability and value to your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How are PTFE lip seals used in the automotive industry? Ensure Leak-Proof Performance in High-Speed, High-Temp Applications

- What are the tolerances for PTFE balls? Achieve Precision in Your Application

- What industries commonly use custom Teflon parts? Critical Applications in Aerospace, Medical & More

- What benefits do PTFE expansion bellows offer in water treatment facilities? Enhance System Reliability & Reduce Costs

- In which industries are PTFE ball valves commonly used? Essential for Chemical Resistance & Purity

- What is PTFE and how does it compare to elastomer rotary seals? Unlock Superior Sealing Performance

- What standards are referenced for PTFE O-rings? Ensure Interchangeability & Superior Performance

- What are the key benefits of using PTFE in seals? Achieve Unmatched Reliability in Extreme Conditions