In short, PTFE ball valves are specified for industries that handle aggressive or highly pure fluids. They are most commonly used in chemical processing, petrochemicals, pharmaceuticals, food and beverage, and pulp and paper manufacturing due to PTFE's exceptional chemical resistance and non-contaminating properties.

The decision to use a PTFE ball valve is almost always driven by a single, critical need: to ensure absolute fluid integrity. This means preventing both the valve from being destroyed by a corrosive fluid and the fluid from being contaminated by the valve itself.

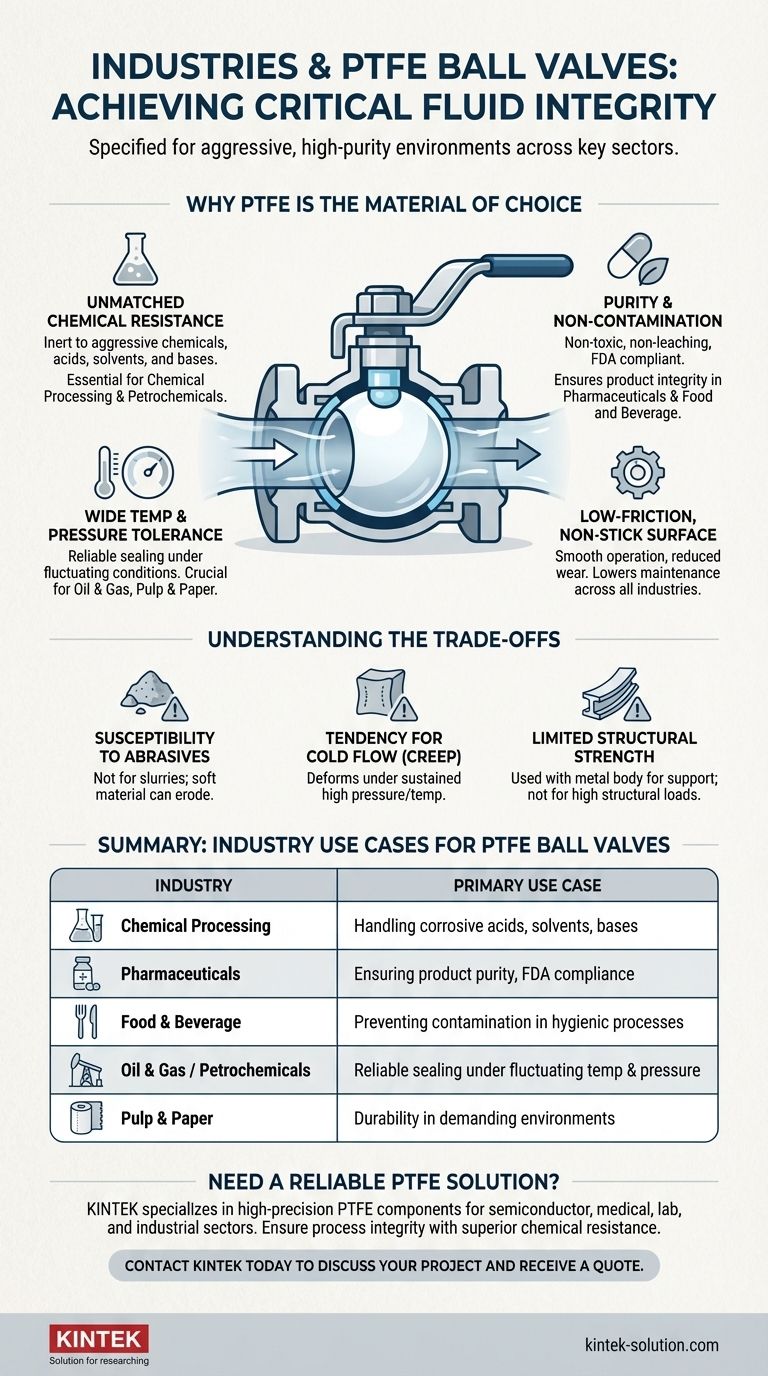

Why PTFE is the Material of Choice

The widespread use of Polytetrafluoroethylene (PTFE) in valve construction is not accidental. It stems from a unique combination of properties that make it an ideal solution for some of the most demanding industrial environments.

Unmatched Chemical Resistance

The primary reason for selecting PTFE is its remarkable inertness. It can withstand a vast range of corrosive and aggressive chemicals that would quickly degrade metals and other polymers.

This makes PTFE valves essential in the chemical processing, petrochemical, and fertilizer industries, where they are used to control the flow of harsh acids, solvents, and bases without failing.

Purity and Non-Contamination

PTFE is a highly pure, non-toxic material that does not leach chemicals or contaminate the media passing through it. This is a non-negotiable requirement in highly regulated sectors.

In the pharmaceutical and food and beverage industries, PTFE's hygienic properties and compliance with FDA standards ensure product purity, preventing any alteration of the final product's taste, color, or composition.

Wide Temperature and Pressure Tolerance

While not the strongest material, PTFE maintains its integrity across a broad spectrum of temperatures and pressures, making it highly reliable for demanding processes.

This stability is crucial in oil and gas, pulp and paper, and other manufacturing settings where processes involve fluctuating temperatures and pressures. PTFE seals and linings prevent leaks under these harsh operating conditions.

Low-Friction, Non-Stick Surface

PTFE's famously low coefficient of friction (the reason it's used for non-stick cookware) provides a practical benefit in valves. It ensures smooth, low-torque operation and prevents media from sticking to and fouling the valve's internal components.

This self-lubricating property reduces wear and tear, extends the valve's service life, and lowers maintenance requirements across all industries.

Understanding the Trade-offs

While its benefits are significant, PTFE is not a universal solution. Understanding its limitations is key to using it correctly and avoiding premature failure.

Susceptibility to Abrasives

PTFE is a relatively soft material. It is not well-suited for applications involving abrasive slurries or fluids containing hard particulates, as these can quickly erode the PTFE seats and seals, leading to leaks.

Tendency for Cold Flow (Creep)

Under sustained high pressure and temperature, PTFE can be prone to "cold flow" or creep, where the material slowly deforms over time. This can compromise the seal's integrity and is a critical design consideration for high-pressure applications.

Limited Structural Strength

Because it is a polymer, PTFE does not have the inherent structural strength of metal. This is why it is most often used as a liner or for the internal "soft parts" (seats and seals) within a robust metal valve body.

Making the Right Choice for Your Application

Selecting the right valve material depends entirely on the demands of your specific process.

- If your primary focus is handling aggressive chemicals: A PTFE-lined valve is the industry standard for safely controlling corrosive media that would destroy most other materials.

- If your primary focus is product purity: PTFE's inert, non-contaminating surface makes it the definitive choice for pharmaceutical, medical, and food-grade applications.

- If your primary focus is general durability in a challenging environment: PTFE components provide excellent sealing and reliability in oil and gas, manufacturing, and water treatment where temperature and pressure fluctuate.

Ultimately, choosing a PTFE ball valve is an investment in process safety, purity, and long-term operational reliability.

Summary Table:

| Industry | Primary Use Case for PTFE Ball Valves |

|---|---|

| Chemical Processing | Handling corrosive acids, solvents, and bases |

| Pharmaceuticals | Ensuring product purity and compliance with FDA standards |

| Food & Beverage | Preventing contamination in hygienic processes |

| Oil & Gas / Petrochemicals | Reliable sealing under fluctuating temperatures and pressures |

| Pulp & Paper | Durability in demanding manufacturing environments |

Need a reliable PTFE solution for your critical application?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and custom labware, for the semiconductor, medical, laboratory, and industrial sectors. We ensure your process integrity with materials that offer superior chemical resistance and non-contaminating properties.

Whether you need a prototype or high-volume production, our custom fabrication services are designed to meet your exact specifications. Contact KINTEK today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing