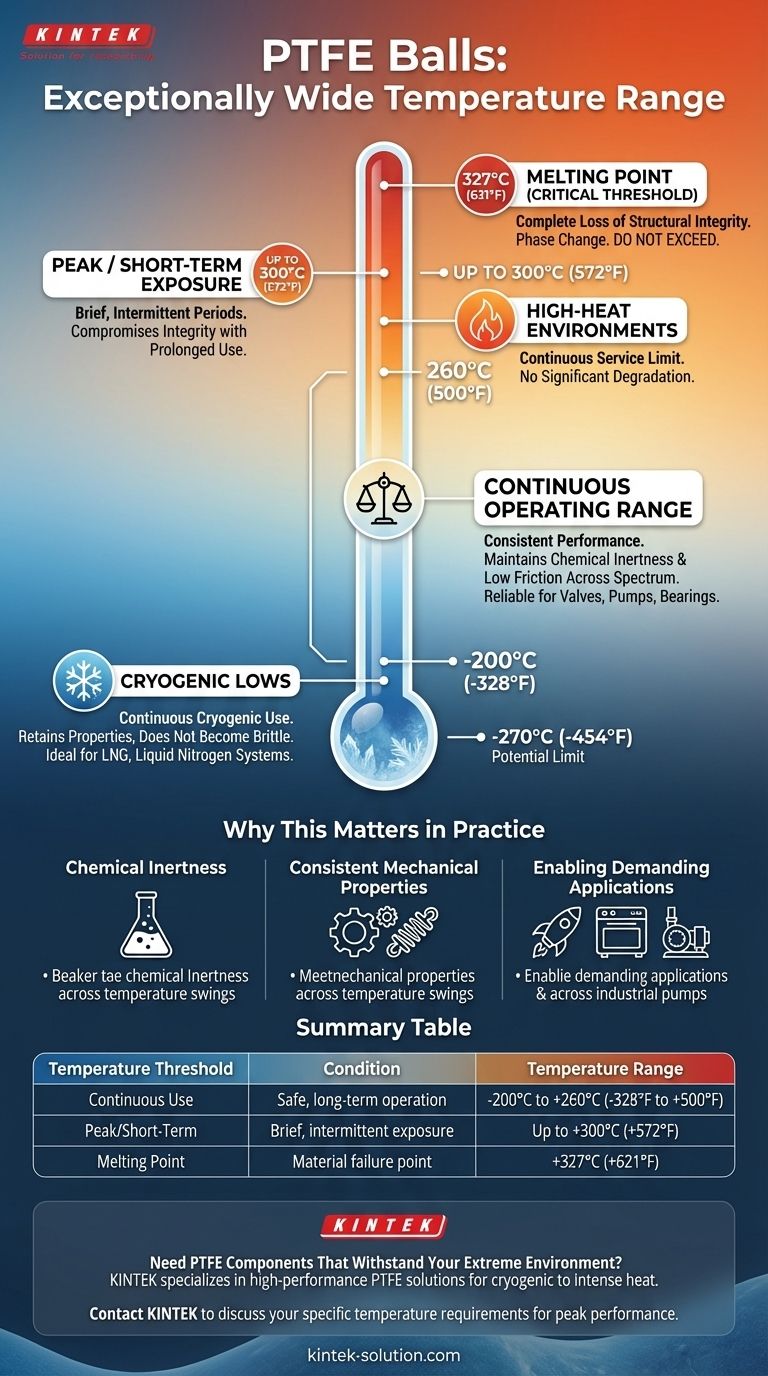

In short, PTFE balls operate within an exceptionally wide temperature range. They are renowned for their thermal stability, reliably performing in continuous service from cryogenic lows of -200°C (-328°F) up to high-heat environments of 260°C (500°F).

The key takeaway is not just the wide temperature range, but PTFE's ability to maintain its critical properties—such as chemical inertness and low friction—across that entire spectrum. This consistency makes it a uniquely reliable material for the most demanding applications.

Understanding the Full Thermal Spectrum

The performance of PTFE (Polytetrafluoroethylene) at temperature extremes is defined by several key thresholds. Understanding the difference between continuous use, short-term peaks, and the ultimate melting point is critical for any engineering application.

The Upper Limit: Continuous vs. Peak Temperature

The most cited and safest maximum operating temperature for PTFE is 260°C (500°F). At this temperature, it can perform continuously without significant degradation of its mechanical or chemical properties.

For brief, intermittent periods, some grades of PTFE can withstand temperatures up to 300°C (572°F). However, prolonged exposure above 260°C will begin to compromise the material's integrity.

The Lower Limit: Cryogenic Performance

PTFE excels in extreme cold. It maintains its properties and does not become brittle at temperatures as low as -200°C (-328°F).

Some data suggests usability in even colder environments, nearing -270°C (-454°F), making it a default choice for many cryogenic systems.

The Melting Point: A Critical Threshold

It is crucial not to confuse the operating temperature with the melting point. PTFE has a very high melting point of approximately 327°C (621°F).

Approaching this temperature causes a phase change and a complete loss of structural integrity. The safe operating limit is set well below this point to ensure a margin of safety.

Why This Temperature Range Matters in Practice

The thermal stability of PTFE is what enables its use in applications where other polymers would fail. This reliability stems from its ability to retain its core characteristics regardless of the temperature.

Maintaining Chemical Inertness

PTFE's legendary resistance to chemicals does not diminish at high or low temperatures. This makes PTFE balls ideal for valves, pumps, and bearings that handle corrosive fluids in heated or cryogenic processes.

Consistent Mechanical Properties

Unlike many materials that become soft when heated or brittle when frozen, PTFE maintains its low-friction surface and mechanical strength. This consistency is vital for components in aerospace, automotive, and industrial machinery that see wide temperature swings.

Enabling Demanding Applications

This combination of properties makes PTFE suitable for everything from high-temperature industrial ovens and engine components to seals and gaskets used in liquid nitrogen or LNG (liquefied natural gas) systems.

Understanding the Trade-offs and Limits

While impressive, the thermal performance of PTFE is not without practical limits that must be respected in any design.

The Risk of Exceeding 260°C

Operating continuously above 260°C is the primary cause of failure. The material will begin to soften, lose its compressive strength, and can start to release toxic fumes, especially as it nears its melting point.

Thermal Expansion and Contraction

Like all materials, PTFE has a coefficient of thermal expansion. In applications with tight tolerances, engineers must account for how much a PTFE ball or component will expand when heated or shrink when cooled to prevent seizure or leaks.

Making the Right Choice for Your Goal

Selecting the right material requires matching its known properties to the demands of your specific environment.

- If your primary focus is continuous high-heat environments: Ensure your normal operating temperature remains at or below 260°C (500°F) to guarantee maximum reliability and component lifespan.

- If your primary focus is cryogenic applications: PTFE is an exceptional choice, retaining its integrity down to -200°C (-328°F), making it suitable for equipment handling liquefied gases.

- If your application involves intermittent temperature spikes: PTFE can tolerate brief excursions toward 300°C (572°F), but this should never be considered a normal or continuous operating condition.

Understanding these specific thermal limits is the key to leveraging PTFE's unique capabilities without risking material failure.

Summary Table:

| Temperature Threshold | Condition | Temperature Range |

|---|---|---|

| Continuous Use | Safe, long-term operation | -200°C to +260°C (-328°F to +500°F) |

| Peak/Short-Term | Brief, intermittent exposure | Up to +300°C (+572°F) |

| Melting Point | Material failure point | +327°C (+621°F) |

Need PTFE Components That Withstand Your Extreme Environment?

KINTEK specializes in manufacturing high-performance PTFE seals, balls, liners, and custom labware that deliver unwavering reliability across the entire thermal spectrum—from cryogenic freezing to intense heat. Our precision production ensures your components maintain critical properties like chemical inertness and low friction, even under the most demanding conditions.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific temperature requirements and get a solution engineered for peak performance.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does the company ensure quality in PTFE wear strips and bands? Achieve Consistent Performance & Dimensional Accuracy

- How do Teflon bearings perform in demanding applications? Superior Performance in Harsh Environments

- What are the thermal properties of PTFE balls? Unlock Extreme Temperature Performance

- What are the types of PTFE fasteners and their common uses? Find the Right Solution for Your Industry

- What is a PTFE gasket? The Ultimate Seal for Extreme Chemicals and Temperatures

- What makes Teflon gland packing superior to other types? Unmatched Chemical Resistance & Low Friction

- What is the purpose of a piston seal? Ensure Peak Performance in Your Hydraulic & Pneumatic Systems

- How do PTFE expansion bellows contribute to reduced maintenance costs? Achieve 40% Lower Costs with Superior Durability