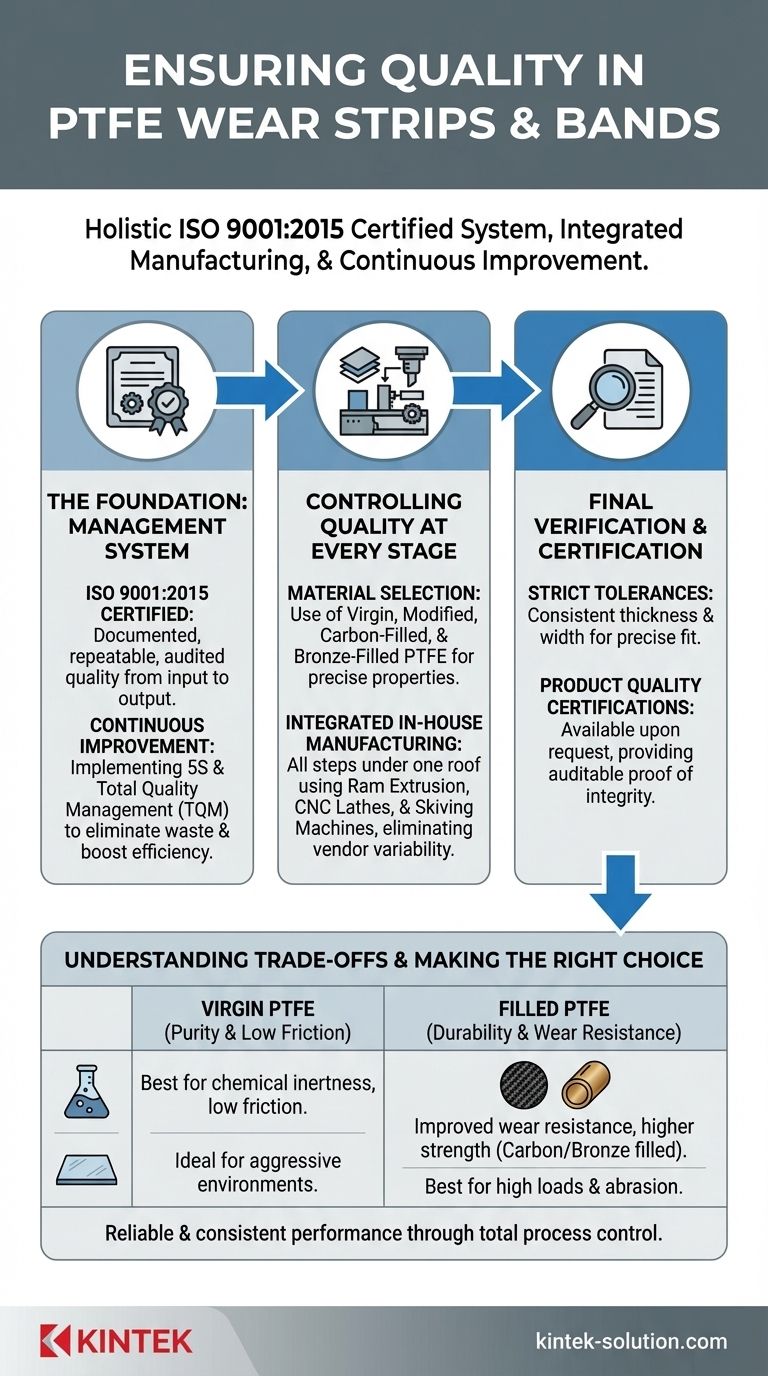

To ensure quality, the company employs a comprehensive, ISO 9001:2015 certified quality management system that governs every stage of production, from raw material selection to final inspection. This framework is supported by integrated in-house manufacturing capabilities and a commitment to continuous improvement methodologies, ensuring consistent dimensional accuracy and material integrity in every PTFE wear strip and band.

The company's approach to quality is not a single inspection point, but a holistic system. It combines a certified process (ISO 9001), complete control over the manufacturing chain, and a culture of continuous improvement to deliver a reliable and consistent product.

The Foundation: A Certified Management System

True quality assurance begins with a documented and audited framework. This provides the structure upon which all process controls are built.

Adherence to ISO 9001:2015

The company operates under a strict ISO 9001:2015 certification. This is not just a certificate; it signifies a documented, repeatable, and audited system for ensuring quality "from input to output."

Every step, from accepting raw materials to shipping finished goods, is governed by this internationally recognized standard.

A Philosophy of Continuous Improvement

Beyond certification, the company implements modern engineering concepts like 5S and Total Quality Management (TQM).

These methodologies foster a culture of proactive improvement, focusing on eliminating waste, improving efficiency, and empowering every team member to maintain the highest quality standards.

Controlling Quality at Every Stage

A certificate is the map, but control over the territory is what matters. Quality is actively managed at each step of the physical manufacturing process.

Starting with the Right Raw Materials

The first quality decision is the material itself. The company manufactures wear strips from a range of specified materials, including:

- Virgin PTFE

- Chemically Modified PTFE

- Carbon Filled PTFE

- Bronze Filled PTFE

By controlling the material inputs, the company ensures the final product has the precise chemical and mechanical properties required for the application.

Integrated In-House Manufacturing

All manufacturing occurs "under one roof" using a comprehensive suite of modern machinery, including Ram Extrusion Machines, CNC Lathes, and Skiving Machines.

This integrated approach is a critical quality control point. It eliminates the variability and potential defects that can arise from relying on outside vendors for key production steps.

Precision and Dimensional Accuracy

The outcome of this process control is a product with strict tolerances on thickness and width.

Whether producing standard rolls (e.g., 2.5 mm thick) or custom-cut parts, the manufacturing process is dialed in to deliver consistent, accurate dimensions that ensure proper fit and performance.

Understanding the Trade-offs: Material Selection

Choosing the right material is a critical aspect of ensuring performance quality. The primary trade-off is between the purity of virgin PTFE and the enhanced mechanical properties of filled grades.

Virgin PTFE

This material offers the highest chemical inertness and the lowest coefficient of friction. It is the ideal choice for applications in chemically aggressive environments or where purity is paramount.

Filled PTFE (Carbon, Bronze)

Adding fillers like carbon or bronze significantly improves key mechanical properties. These grades offer superior wear resistance, higher compressive strength, and reduced creep (deformation under load).

The trade-off is a potential reduction in chemical resistance compared to virgin PTFE and a slightly higher coefficient of friction.

Final Verification and Certification

The quality process concludes with final verification, providing the customer with documented assurance of the product's integrity.

Complete Product Quality Certifications

Upon request, the company can provide complete product quality certifications. This documentation serves as a final guarantee that the supplied wear strips and bands meet the specified material and dimensional standards, giving you auditable proof of quality.

Making the Right Choice for Your Application

Understanding this quality framework empowers you to select the right product with confidence.

- If your primary focus is chemical purity and low friction: Virgin PTFE is the definitive choice due to its unmatched inertness.

- If your primary focus is durability under high loads or abrasive conditions: A filled grade like Carbon or Bronze Filled PTFE will provide superior wear resistance.

- If your primary focus is a precise, repeatable fit: Rely on the company's process controls that ensure strict dimensional tolerances for both standard and custom sizes.

By controlling the entire process from raw material to certified final part, the system is designed to deliver consistent performance you can trust.

Summary Table:

| Quality Control Stage | Key Activities & Methods |

|---|---|

| Management System | ISO 9001:2015 certified framework, Continuous Improvement (5S, TQM) |

| Material Selection | Use of Virgin, Modified, Carbon-Filled, or Bronze-Filled PTFE |

| Manufacturing | Integrated in-house production (Ram Extrusion, CNC, Skiving) |

| Verification | Strict dimensional tolerances, Final product quality certifications available |

Need reliable PTFE components with guaranteed quality?

KINTEK's ISO 9001:2015 certified manufacturing process ensures every PTFE wear strip, seal, liner, or piece of labware meets the highest standards for dimensional accuracy and material integrity. From prototypes to high-volume orders, we deliver consistent performance for the semiconductor, medical, laboratory, and industrial sectors.

Contact KINTEK today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts