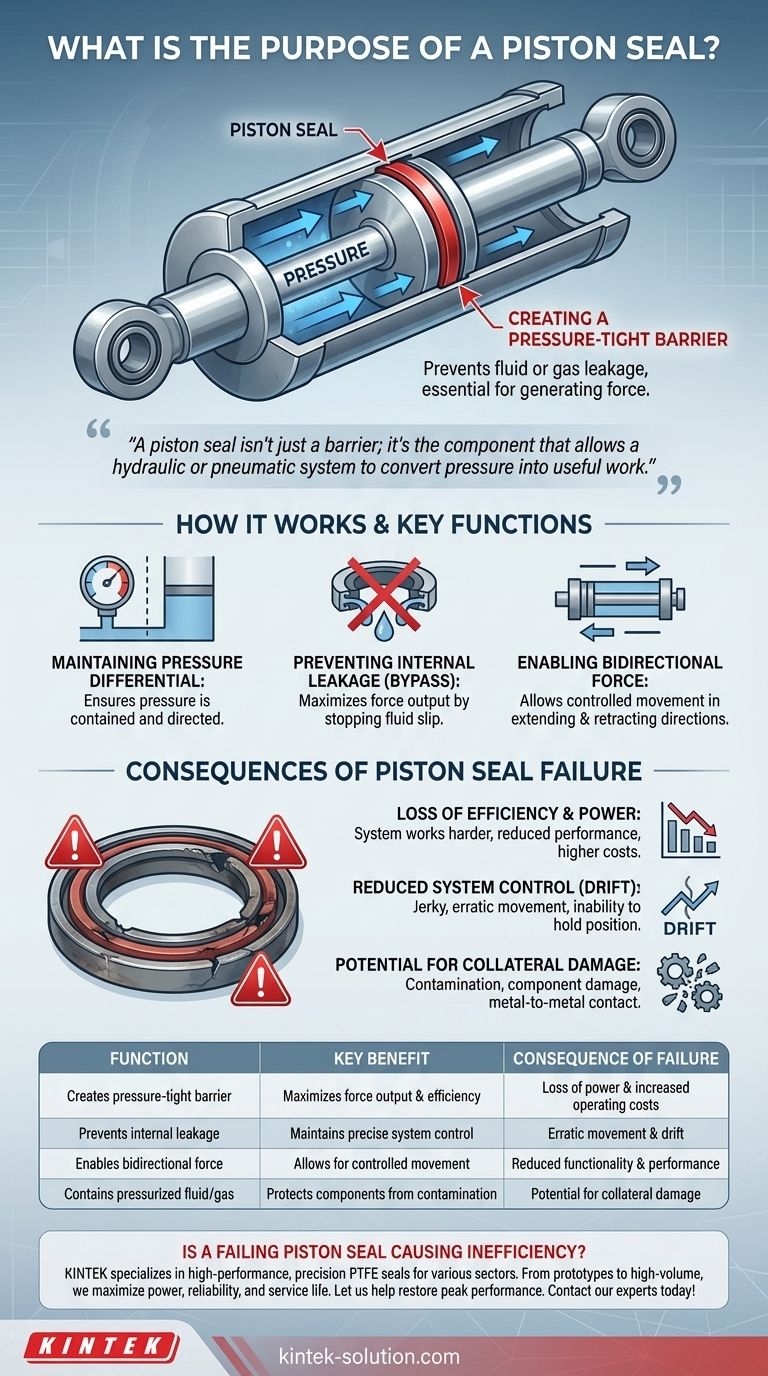

At its core, the purpose of a piston seal is to create a pressure-tight barrier. This seal prevents the operating fluid (like hydraulic oil) or gas (like compressed air) from leaking past the piston as it moves within a cylinder. This function is absolutely essential for generating and maintaining the force that makes the system work.

A piston seal isn't just a barrier; it's the component that allows a hydraulic or pneumatic system to convert pressure into useful work. Its failure to maintain a seal directly translates to a loss of power, efficiency, and control.

The Core Function: Maintaining Pressure Differential

A hydraulic or pneumatic cylinder works by applying pressurized fluid or gas to one face of a piston, forcing it to move. The piston seal is the critical component that ensures this pressure is contained and directed effectively.

How a Piston Seal Works

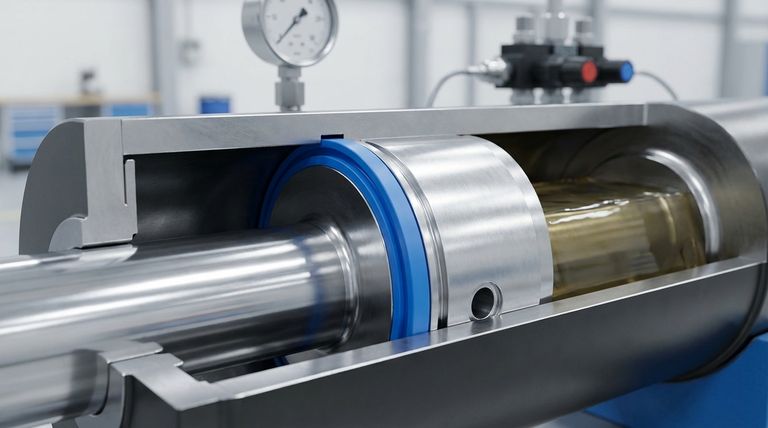

A piston seal is typically an elastic ring housed in a groove on the piston's outer diameter. It is designed to press firmly against the inner wall of the cylinder bore, creating a tight, dynamic barrier. When pressure is applied, it energizes the seal, pushing it even more forcefully against the cylinder wall to improve the seal's integrity.

Preventing Internal Leakage (Bypass)

The primary job of the seal is to prevent internal leakage, also known as "bypass." This is when the pressurized fluid or gas slips from the high-pressure side of the piston to the low-pressure side. By preventing this, the seal ensures the full pressure difference is maintained across the piston head, maximizing the force output.

Enabling Bidirectional Force

In double-acting cylinders, which can exert force in both extending and retracting directions, seals on the piston are what make this possible. They allow pressure to be built up on either side of the piston while sealing off the opposing side, enabling controlled movement in both directions.

The Consequences of Piston Seal Failure

A worn, damaged, or improperly installed piston seal is not a minor issue; it directly undermines the entire function of the actuator. The consequences range from gradual degradation to complete system failure.

Loss of Efficiency and Power

This is the most common symptom of a failing seal. As fluid or gas bypasses the piston, the system must work harder to achieve the desired force or speed. This wasted energy manifests as reduced performance and increased operating costs.

Reduced System Control

A leaking piston seal can cause jerky, erratic, or slow cylinder movement. The actuator may struggle to hold a position under load, as the pressure constantly bleeds from one side of the piston to the other, causing it to "drift."

Potential for Collateral Damage

A failing seal can disintegrate, introducing debris into the hydraulic fluid or pneumatic system. This contamination can damage other critical components, such as pumps and valves, leading to far more expensive and complex repairs. In severe cases, it can allow metal-to-metal contact between the piston and cylinder, destroying the actuator.

Making the Right Choice for Your Goal

Understanding the piston seal's function is key to diagnosing issues and ensuring system reliability.

- If your primary focus is maximizing system efficiency: Recognize that the piston seal is a primary defense against energy loss, and its condition is directly tied to the power output of your actuator.

- If your primary focus is reliability and safety: Treat the piston seal as a critical failure point, especially in applications where the cylinder must hold a load securely without drifting.

- If your primary focus is troubleshooting performance issues: When a cylinder loses force, speed, or positioning accuracy, a leaking piston seal should be a primary suspect for internal bypass.

Ultimately, this small component is the linchpin that allows the entire hydraulic or pneumatic system to function as designed.

Summary Table:

| Function | Key Benefit | Consequence of Failure |

|---|---|---|

| Creates a pressure-tight barrier | Maximizes force output and efficiency | Loss of power and increased operating costs |

| Prevents internal leakage (bypass) | Maintains precise system control | Erratic movement and inability to hold position (drift) |

| Enables bidirectional force in double-acting cylinders | Allows for controlled movement in both directions | Reduced functionality and system performance |

| Contains pressurized fluid/gas | Protects other system components from contamination | Potential for collateral damage to pumps and valves |

Is a failing piston seal causing inefficiency or a loss of control in your equipment?

KINTEK specializes in manufacturing high-performance, precision PTFE seals for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a reliable standard component or a custom-fabricated solution—from prototype to high-volume production—our seals are engineered to maximize your system's power, reliability, and service life.

Let us help you eliminate internal leakage and restore peak performance. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry