The primary types of PTFE fasteners are screws, nuts, bolts, and washers, each engineered to leverage Polytetrafluoroethylene's unique properties. They are chosen for applications where exceptional chemical resistance, non-reactivity, and low friction are more critical than raw mechanical strength, such as in medical devices, chemical processing, and electronics.

While the common forms are screws, nuts, and bolts, the true decision lies in understanding the material itself. The choice between solid virgin PTFE, a specialized "filled" PTFE, or a PTFE-coated metal fastener is what ultimately determines performance in a specific application.

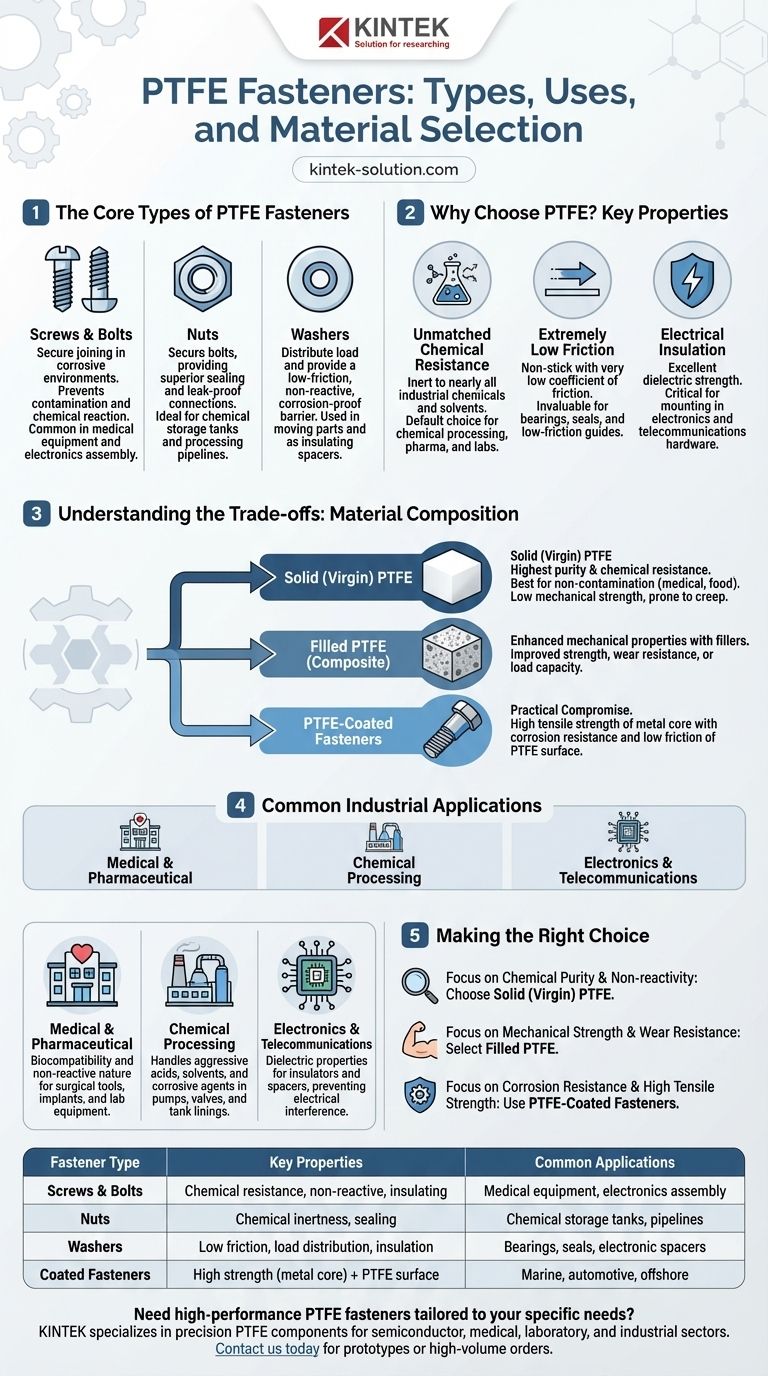

The Core Types of PTFE Fasteners

Each fastener type serves a familiar mechanical function but is deployed in environments where conventional materials would quickly fail.

PTFE Screws and Bolts

These fasteners provide secure joining in highly corrosive or sensitive environments. They are specified when preventing contamination and chemical reaction is the primary goal.

PTFE screws and bolts are common in medical equipment and electronics assembly, where their non-reactive and electrically insulating properties are essential.

PTFE Nuts

PTFE nuts are used to secure bolts and screws, often providing superior sealing properties compared to metal alternatives. This helps create leak-proof connections in fluid or gas systems.

Their chemical inertness makes them ideal for securing components in chemical storage tanks and processing pipelines.

PTFE Washers

PTFE washers are used to distribute the load of a threaded fastener. Their most important characteristic, however, is providing an extremely low-friction, non-reactive, and corrosion-proof barrier between surfaces.

They are frequently used in assemblies with moving parts or as insulating spacers in electronic components.

Why Choose PTFE? The Key Properties

The decision to use a PTFE fastener is almost always driven by the material's unique characteristics, not its mechanical strength.

Unmatched Chemical Resistance

PTFE is inert to nearly all industrial chemicals and solvents. This makes it the default choice for equipment used in chemical processing, pharmaceutical manufacturing, and laboratories.

Extremely Low Friction

Known for its non-stick properties, PTFE has one of the lowest coefficients of friction of any solid. This is invaluable for applications involving sliding parts, such as in bearings, seals, and low-friction guides.

Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. This property is critical for mounting and securing components in electronics and telecommunications hardware.

Understanding the Trade-offs: Material Composition

Not all PTFE is the same. The performance of a fastener depends heavily on its specific composition, which creates a clear hierarchy of trade-offs between purity and strength.

Solid (Virgin) PTFE: The Purity Standard

Fasteners made from 100% pure, or "virgin," PTFE offer the highest level of chemical resistance and purity. However, they have relatively low mechanical strength and can be prone to "creep" or deforming under a sustained load.

This type is best for applications where non-contamination is the absolute priority, such as in medical devices or food production.

Filled PTFE: Enhancing Mechanical Properties

To overcome the mechanical limitations of virgin PTFE, fillers are added to the raw material. This creates a composite with enhanced properties.

Common fillers include fiberglass for general-purpose strength, carbon or graphite for improved wear resistance in bearings, and stainless steel or bronze for high-load applications.

PTFE-Coated Fasteners: A Practical Compromise

This common category involves a standard metal fastener (usually steel) coated with a thin layer of PTFE. This approach provides the high tensile strength of the metal core while adding the corrosion resistance and low-friction surface of PTFE.

These are widely used in offshore, marine, and automotive industries where both strength and durability are required. Their primary weakness is that a scratch or damage to the coating can compromise its protective benefit.

Common Industrial Applications

The unique properties of PTFE fasteners make them indispensable in several key sectors.

Medical and Pharmaceutical

Due to its biocompatibility and non-reactive nature, PTFE is used for fasteners in surgical tools, implantable devices, and laboratory equipment where sterilization and purity are non-negotiable.

Chemical Processing

In plants that handle aggressive acids, solvents, and other corrosive agents, PTFE fasteners are used to assemble valves, pumps, gaskets, and tank linings to prevent degradation and failure.

Electronics and Telecommunications

The excellent dielectric properties of PTFE make it ideal for fasteners used as insulators and spacers in high-frequency electronic components, preventing electrical interference and short circuits.

Making the Right Choice for Your Application

Selecting the correct fastener requires a clear understanding of your primary operational demand.

- If your primary focus is chemical purity and non-reactivity: Choose fasteners made from solid, virgin PTFE.

- If your primary focus is mechanical strength and wear resistance: Select a filled PTFE fastener with a composite material like carbon, fiberglass, or stainless steel.

- If your primary focus is corrosion resistance with high tensile strength: A PTFE-coated metal fastener is often the most practical and cost-effective solution.

Ultimately, selecting the right PTFE fastener means matching the material's specific grade and form to the unique demands of your environment.

Summary Table:

| Fastener Type | Key Properties | Common Applications |

|---|---|---|

| Screws & Bolts | Chemical resistance, non-reactive, insulating | Medical equipment, electronics assembly |

| Nuts | Chemical inertness, sealing | Chemical storage tanks, pipelines |

| Washers | Low friction, load distribution, insulation | Bearings, seals, electronic spacers |

| Coated Fasteners | High strength (metal core) + PTFE surface | Marine, automotive, offshore |

Need high-performance PTFE fasteners tailored to your specific needs? KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, labware, and fasteners—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, we deliver solutions that prioritize chemical resistance, low friction, and durability. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What material are PTFE ring gaskets made from? Unlock Superior Chemical & Thermal Sealing

- What are the chemical resistance properties of Teflon (PTFE) balls? Unmatched Inertness for Harsh Environments

- How can PTFE be modified for different applications? Tailor Performance with Fillers and Processing

- How did PTFE lined butterfly valves address corrosion resistance challenges? Provide a Robust Barrier Against Corrosive Media

- Why are Metal-Polymer Bronze Backed PTFE Plain Bearings considered versatile? Unlock Maintenance-Free, High-Performance Solutions

- How should PTFE lined butterfly valves be maintained? A Proactive Guide to Maximize Uptime

- Why is ePTFE suitable for aerospace applications? Achieve Lightweight Reliability in Extreme Conditions

- What precautions should be taken when using PTFE gaskets in high-pressure applications? Ensure a Reliable, Leak-Free Seal