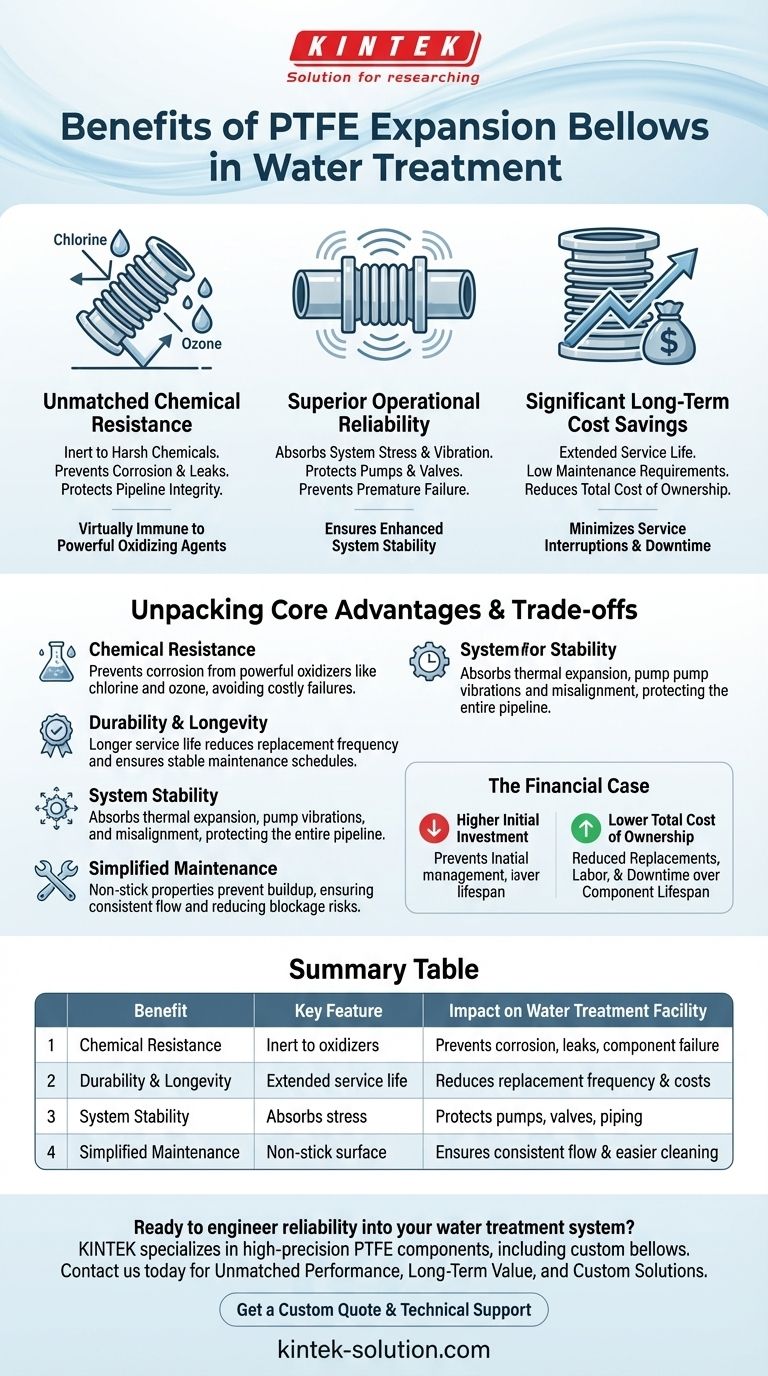

In a water treatment facility, PTFE expansion bellows offer three primary benefits: unmatched resistance to corrosive chemicals like chlorine and ozone, superior operational reliability by absorbing system stress and vibration, and significant long-term cost savings due to their extended service life and low maintenance requirements. They directly address the core challenges of maintaining pipeline integrity in a harsh chemical environment.

The decision to use PTFE expansion bellows is less about a single component and more about a strategic investment in the entire system's longevity and reliability. Their higher upfront cost is consistently offset by preventing costly chemical corrosion, minimizing service interruptions, and reducing the total cost of ownership over time.

Unpacking the Core Advantages of PTFE Bellows

To understand the value of PTFE bellows, we must look beyond their function as a flexible connector and analyze their material properties in the specific context of water treatment operations.

Unmatched Chemical Resistance

The most critical advantage is PTFE's inertness. Water treatment processes rely on powerful oxidizing agents like chlorine and ozone, which aggressively corrode metals and degrade many other plastics.

PTFE is virtually immune to these chemicals, preventing corrosion that would otherwise lead to leaks, component failure, and costly downtime.

Superior Durability and Longevity

This chemical resistance directly translates to a longer service life. Where other materials might fail prematurely, PTFE bellows maintain their integrity for extended periods.

This durability reduces the frequency of replacements, ensuring a more stable and predictable maintenance schedule and minimizing interruptions to the water supply.

Enhanced System Stability

Pipelines are not static; they experience stress from thermal expansion, pump vibrations, and slight misalignments. PTFE bellows are engineered to absorb these forces.

By accommodating this movement, they protect the entire pipeline system—including pipes, pumps, and valves—from fatigue, stress fractures, and premature failure.

Simplified Maintenance and Operation

PTFE has non-stick, or non-adhesive, properties. This is crucial in water treatment, as it prevents mineral deposits, sludge, and other materials from building up inside the bellow.

This ensures a consistent and efficient fluid flow, reduces the risk of blockages, and simplifies any cleaning or inspection routines.

The Financial and Operational Case for PTFE

While the technical benefits are clear, the impact on a facility's budget and operational efficiency is what makes PTFE a compelling choice.

Streamlined Installation

PTFE expansion bellows are lightweight compared to metallic alternatives. This simplifies handling and makes installation faster and easier, often requiring less labor and no specialized equipment.

Reduced Downtime and Interruptions

Component failure is a primary cause of operational downtime. By resisting the root causes of failure—corrosion and system stress—PTFE bellows dramatically improve reliability.

For a critical utility like a water treatment plant, this means a more consistent water supply and better allocation of maintenance resources to other tasks.

Understanding the Trade-offs

An objective evaluation requires acknowledging the primary consideration when specifying PTFE components.

Higher Initial Investment

The most significant factor is the upfront cost. PTFE expansion bellows are typically more expensive to purchase than those made from materials like rubber or certain metals.

This initial expense can be a barrier. However, viewing it in isolation is a mistake. The true value is realized by calculating the total cost of ownership, which accounts for the dramatic reduction in replacement, labor, and downtime costs over the component's lifespan.

Making the Right Choice for Your Facility

Selecting the right expansion bellow depends entirely on your primary operational and financial goals.

- If your primary focus is maximizing operational uptime: PTFE is the superior choice due to its extreme durability and resistance to chemical failure in water treatment environments.

- If your primary focus is minimizing lifecycle costs: The long-term savings from reduced maintenance, fewer replacements, and avoided downtime make PTFE a sound financial investment despite the higher initial cost.

- If your primary focus is protecting system integrity: PTFE's ability to absorb vibration and thermal expansion provides critical protection for expensive downstream equipment and the entire piping infrastructure.

Ultimately, choosing PTFE expansion bellows is a proactive decision to engineer reliability into your water treatment system from the start.

Summary Table:

| Benefit | Key Feature | Impact on Water Treatment Facility |

|---|---|---|

| Chemical Resistance | Inert to chlorine, ozone, and other oxidizers | Prevents corrosion, leaks, and component failure |

| Durability & Longevity | Extended service life in harsh environments | Reduces replacement frequency and maintenance costs |

| System Stability | Absorbs thermal expansion, vibration, and misalignment | Protects pumps, valves, and piping from stress damage |

| Simplified Maintenance | Non-stick surface prevents buildup and blockages | Ensures consistent flow and easier cleaning routines |

Ready to engineer reliability into your water treatment system?

PTFE expansion bellows are a strategic investment in your facility's longevity and operational efficiency. At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom bellows, for the demanding environments of the water treatment, industrial, and semiconductor industries.

Our expertise ensures you get a component that delivers:

- Unmatched Performance: Superior chemical resistance and durability tailored to your specific application.

- Long-Term Value: Reduce total cost of ownership by minimizing downtime and replacement costs.

- Custom Solutions: From prototypes to high-volume orders, we fabricate components to your exact specifications.

Contact us today to discuss how our PTFE solutions can protect your system and your budget.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining