Yes, expanded PTFE is exceptionally suitable for food and pharmaceutical applications. Its suitability is not just a matter of compliance but is rooted in a unique combination of properties, including its chemical inertness, non-toxic nature, and high-temperature resistance. Because of this, it is widely used for sealing, processing, and packaging equipment where purity and safety are non-negotiable.

The core reason for PTFE's widespread adoption in these sensitive industries goes beyond simple non-toxicity. It is the material's ability to actively maintain a hygienic environment through its non-stick surface, resistance to sterilization temperatures, and inability to contaminate or absorb the products it contacts.

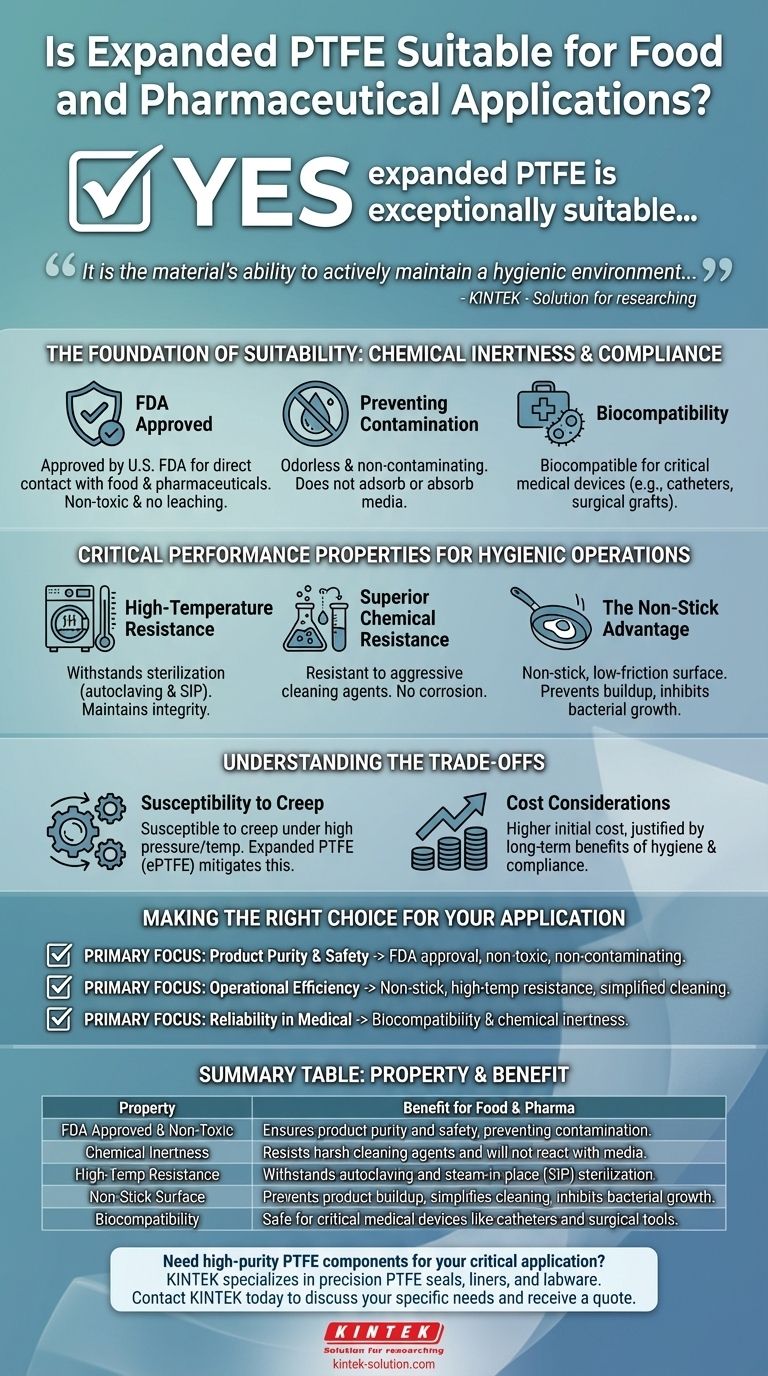

The Foundation of Suitability: Chemical Inertness and Compliance

The primary requirement for any material in the food and pharmaceutical space is that it must not harm the end user or compromise the product. PTFE excels in this regard due to its fundamental chemical makeup.

FDA Approval and Material Purity

Polytetrafluoroethylene (PTFE) is a polymer that is approved by the U.S. Food and Drug Administration (FDA) for direct contact with food and pharmaceuticals. This approval is a testament to its inherent purity and stability.

The material is non-toxic and does not leach harmful substances, ensuring it meets the stringent regulatory requirements governing these industries.

Preventing Contamination and Flavor Transfer

PTFE is both odorless and non-contaminating. This means it will not impart any unwanted taste, smell, or chemical component into the food, beverage, or drug it touches.

Furthermore, the material does not adsorb or absorb the media it is sealing, which prevents cross-contamination between different batches.

Biocompatibility in Medical Applications

In medical and pharmaceutical contexts, PTFE's safety profile is further confirmed by its biocompatibility. The material is inert, meaning it does not cause a reaction when introduced to the body.

This property makes it a trusted material for life-saving equipment like catheters, surgical grafts, syringes, and bio-containment vessels, where reliability and patient safety are paramount.

Critical Performance Properties for Hygienic Operations

Beyond its inherent safety, PTFE's physical properties provide significant operational advantages that enhance efficiency and hygiene in processing environments.

High-Temperature Resistance for Sterilization

Food and pharmaceutical equipment must be regularly cleaned and sterilized. PTFE can withstand the high temperatures required for sterilization processes like autoclaving and steam-in-place (SIP).

This thermal stability ensures that seals and components maintain their integrity and do not degrade, even after repeated sterilization cycles.

Superior Chemical Resistance

Processing and cleaning often involve aggressive chemicals. PTFE is resistant to nearly all industrial chemicals and solvents, ensuring that components do not corrode or break down when exposed to harsh cleaning agents.

The Non-Stick Advantage

PTFE is famous for its non-stick, low-friction surface. In hoppers, chutes, and processing vessels, this prevents product buildup, which improves production flow and drastically simplifies cleaning.

In medical devices like catheters, this non-stick surface can help inhibit the growth of bacteria, reducing the risk of infections.

Understanding the Trade-offs

While PTFE is a superior material for these applications, no single solution is perfect. Understanding its limitations is key to proper implementation.

Susceptibility to Creep

Under sustained high pressure and temperature, standard PTFE can be susceptible to creep, or cold flow. This can be a concern for critical sealing applications where gasket integrity is essential.

Expanded PTFE (ePTFE) and filled PTFE grades are often engineered to mitigate this issue, providing better dimensional stability than virgin PTFE.

Cost Considerations

PTFE is a high-performance polymer and is generally more expensive than common elastomers or commodity plastics. Its selection must be justified by the performance and safety requirements of the application.

For highly regulated or critical processes, the long-term benefits of hygiene, reliability, and compliance often outweigh the initial material cost.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary goal. PTFE's versatility makes it a strong candidate for several distinct objectives.

- If your primary focus is product purity and safety: PTFE's FDA approval, non-toxic nature, and inability to contaminate make it one of the safest choices available.

- If your primary focus is operational efficiency and cleanability: The material's non-stick surface and resistance to high-temperature sterilization reduce downtime and ensure a hygienic process.

- If your primary focus is reliability in medical devices: PTFE's proven biocompatibility and chemical inertness provide the safety and performance required for critical healthcare applications.

Ultimately, expanded PTFE provides a powerful combination of safety, compliance, and performance that makes it an ideal material for the demanding environments of the food and pharmaceutical industries.

Summary Table:

| Property | Benefit for Food & Pharma Applications |

|---|---|

| FDA Approved & Non-Toxic | Ensures product purity and safety, preventing contamination. |

| Chemical Inertness | Resists harsh cleaning agents and will not react with media. |

| High-Temp Resistance | Withstands autoclaving and steam-in-place (SIP) sterilization. |

| Non-Stick Surface | Prevents product buildup, simplifies cleaning, and inhibits bacterial growth. |

| Biocompatibility | Safe for critical medical devices like catheters and surgical tools. |

Need high-purity PTFE components for your critical application?

KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered to meet the stringent demands of food and pharmaceutical applications, ensuring compliance, safety, and operational efficiency.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing the material integrity and performance your process requires.

Contact KINTEK today to discuss your specific needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are Teflon sheets important for sublimation printing? Protect Your Press & Ensure Perfect Prints

- What makes PTFE superior in terms of chemical resistance compared to rubber seals? The Key to Unmatched Reliability

- What factors should be considered when selecting a PTFE lined butterfly valve? Ensure Long-Term Performance in Harsh Environments

- What is the temperature range that PTFE Teflon washers can withstand? From -200°C to +260°C for Extreme Conditions

- What regulatory standards do Medical Grade PTFE Liners meet? Ensuring FDA & ISO Compliance for Patient Safety

- What is a PTFE lined ball valve? A Corrosion-Resistant Solution for Harsh Chemicals

- In which industries are PTFE bellows commonly used due to their chemical resistivity? Essential for Corrosive & Pure Environments

- What factors should be considered when selecting Teflon gland packing for equipment? Ensure Long-Term Sealing Performance