Selecting the correct Teflon gland packing is a critical decision that hinges on three primary factors: the specific operational conditions (temperature, pressure, and chemical exposure), the type of equipment being sealed (such as pumps or valves), and compatibility with the process media. A precise match between the packing and these factors is essential for ensuring a reliable, long-lasting seal and preventing premature failure.

The goal is not merely to select a packing that fits, but to choose a sealing solution that aligns with the complete lifecycle of your equipment. This requires looking past the initial purchase price to consider long-term performance, maintenance costs, and overall operational reliability.

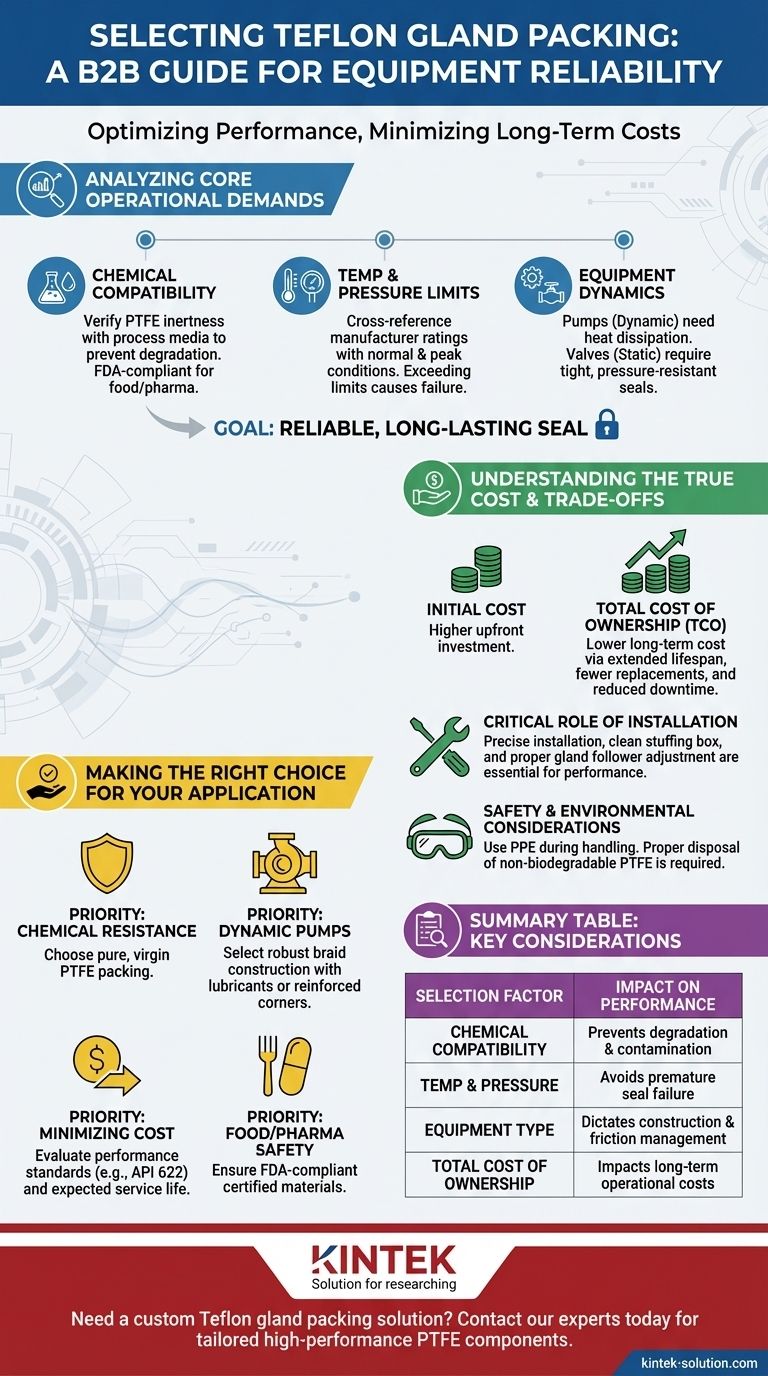

Analyzing Core Operational Demands

The performance of any gland packing is dictated by its environment. A detailed analysis of your system's demands is the foundational step in the selection process.

Chemical Compatibility

Teflon (PTFE) is renowned for being chemically inert, making it suitable for a vast range of aggressive media. However, you must always verify its compatibility with the specific chemicals in your process.

This ensures the packing will not degrade, swell, or leach, which could compromise the seal and contaminate the process fluid. For food or pharmaceutical applications, selecting a packing made from FDA-compliant materials is non-negotiable.

Temperature and Pressure Limits

While Teflon has a wide temperature tolerance, different packing constructions have distinct operational limits. Exceeding these specifications is a common cause of seal failure.

Always cross-reference the manufacturer's data sheet for maximum temperature and pressure ratings against your system's normal and peak operating conditions.

Equipment Type and Dynamics

The mechanical demands on the packing vary significantly between different types of equipment. This dictates the ideal packing construction.

Pumps involve a dynamic, rotating shaft, requiring packing that can dissipate heat and manage friction effectively. In contrast, valves are largely static applications, where the packing must provide a tight seal against pressure with infrequent movement.

Understanding the True Cost and Trade-offs

An effective selection process evaluates both performance and economics. The best choice is often not the cheapest one upfront but the one that delivers the most value over its service life.

Initial Cost vs. Total Cost of Ownership

Teflon gland packing often has a higher initial cost compared to some conventional materials. This initial investment, however, frequently yields a lower Total Cost of Ownership (TCO).

The return on investment comes from its extended lifespan, which leads to fewer replacements, reduced labor costs, and minimized equipment downtime.

The Critical Role of Installation

The superior performance of Teflon packing can be completely negated by improper installation. It is not a "fit-and-forget" component.

Common mistakes like over-tightening the gland follower can prevent necessary leakage for lubrication and cause premature wear on both the packing and the shaft. A clean stuffing box and precisely cut rings are prerequisites for success.

Safety and Environmental Considerations

While the final PTFE product is stable and safe, proper handling is important. Use appropriate Personal Protective Equipment (PPE) and ensure good ventilation to avoid inhaling any dust during installation.

It's also important to recognize that PTFE is not biodegradable, so end-of-life packing must be disposed of according to local environmental regulations.

Making the Right Choice for Your Application

Use your operational priorities to guide your final selection.

- If your primary focus is chemical resistance: Prioritize a pure, virgin PTFE packing and confirm its compatibility with your specific process media.

- If your primary focus is dynamic applications (pumps): Select a packing with a robust braid construction, potentially with lubricating agents or reinforced corners to manage friction and heat.

- If your primary focus is minimizing long-term cost: Look beyond the initial price and evaluate the packing's compliance with performance standards (like API 622), expected service life, and maintenance requirements.

- If your primary focus is food or pharmaceutical safety: Ensure the packing is explicitly certified as being made from FDA-compliant materials.

A methodical approach to selection transforms gland packing from a simple component into a strategic asset for operational reliability.

Summary Table:

| Selection Factor | Key Consideration | Impact on Performance |

|---|---|---|

| Chemical Compatibility | Verify inertness with process media | Prevents degradation and contamination |

| Temperature & Pressure | Check against operational limits | Avoids premature seal failure |

| Equipment Type | Dynamic (pumps) vs. Static (valves) | Dictates construction and friction management |

| Total Cost of Ownership | Initial price vs. lifespan/maintenance | Impacts long-term operational costs |

Need a custom Teflon gland packing solution for your specific application? KINTEK manufactures high-performance PTFE components, including seals and gland packing, for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision and durability to ensure your equipment operates reliably. Whether you need prototypes or high-volume orders, our custom fabrication expertise delivers a perfect match for your operational demands. Contact our experts today to discuss your sealing requirements and receive a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry