To select the right PTFE lined butterfly valve, you must primarily evaluate four key areas: the chemical compatibility of the process media with the PTFE liner, the system's operating pressure and temperature ranges, the required flow control characteristics, and any physical installation constraints. These factors ensure the valve not only fits your system but also provides safe, long-term performance without structural failure or leakage in demanding environments.

The core task is not simply matching specifications on a data sheet. It's about understanding that a PTFE lined valve is a specialized solution for controlling corrosive, high-purity, or extreme-temperature media. Your selection process is fundamentally an exercise in risk management for your most critical applications.

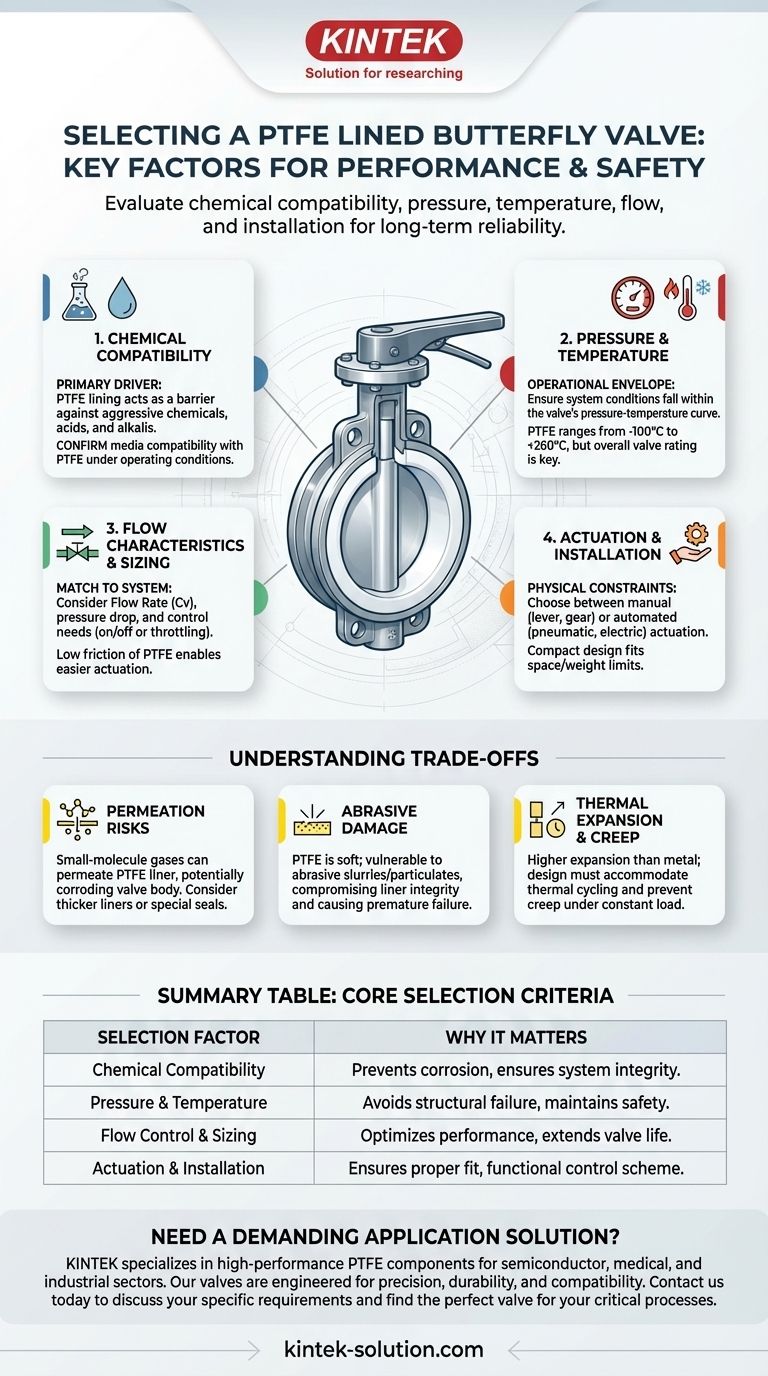

Deconstructing the Core Selection Criteria

A successful selection goes beyond the surface-level specs. You must understand how each criterion relates to the valve's construction and your system's operational goals.

Chemical Compatibility: The Primary Driver

The defining feature of these valves is the polytetrafluoroethylene (PTFE) lining. This inert fluoropolymer acts as a protective barrier between the process media and the valve's metallic body.

PTFE offers exceptional resistance to a wide range of aggressive chemicals, including strong acids, alkalis, and oxidants. Your first step is to confirm that your specific chemical media is fully compatible with PTFE under your operating conditions.

Pressure and Temperature: Defining the Operational Envelope

Every valve has a defined pressure-temperature rating, often shown as a curve. You must ensure your system's operating conditions fall safely within this envelope.

PTFE itself has a remarkable temperature range, remaining functional from cryogenic temperatures (-100°C) up to high heat (around 200-260°C). However, the valve's overall rating is determined by all its components, including the valve body, stem, and seals. Pressure and temperature ratings are often inversely related; as temperature increases, the maximum allowable pressure typically decreases.

Flow Characteristics and Sizing: Matching the Valve to the System

Proper sizing is critical for both performance and valve longevity. This involves more than just matching the pipe diameter.

You must consider the required flow rate (Cv), the allowable pressure drop across the valve, and the nature of flow control. Butterfly valves are suitable for both on/off isolation and throttling applications. The low coefficient of friction of the PTFE liner contributes to easier actuation and smoother disc movement.

Actuation and Installation: The Physical Constraints

Finally, consider the physical and operational realities of your facility.

Decide whether manual operation (hand lever or gear operator) or automated actuation (pneumatic, electric) is more suitable for your process control scheme. Additionally, the lightweight and compact nature of butterfly valves makes them ideal for systems with space or weight limitations.

Understanding the Trade-offs

While highly effective, PTFE lined valves are not a universal solution. An objective evaluation requires acknowledging their limitations.

Permeation with Certain Media

While PTFE is chemically inert, it is not impermeable. Certain small-molecule gases (e.g., chlorine, hydrogen, bromine) can slowly permeate through the liner over time, potentially reaching and corroding the valve body from within. For these services, you may need a valve with a thicker liner or a specific stem seal design.

Susceptibility to Abrasive Damage

PTFE is a relatively soft material. It is an excellent choice for clean liquids and gases but can be damaged by abrasive slurries or sharp particulates. This can compromise the integrity of the liner and lead to premature failure.

Thermal Expansion and Creep

PTFE has a higher coefficient of thermal expansion than metal. The valve must be engineered to accommodate this expansion and contraction to maintain a tight seal across its entire temperature range. It can also be subject to "creep" or cold flow under a constant load, which is why a well-designed sealing mechanism is critical.

Making the Right Selection for Your Application

Use your primary goal to guide your final decision.

- If your primary focus is aggressive chemical processing: Prioritize a valve with a thick, high-quality liner and a robust stem sealing system to guard against permeation and fugitive emissions.

- If your primary focus is high-purity or sanitary applications: Verify the valve carries necessary certifications (e.g., FDA, USP Class VI) and features a design that minimizes crevices where media can be trapped.

- If your primary focus is general corrosion resistance: A standard, well-engineered PTFE lined valve will often provide the necessary protection and performance without the cost of highly specialized features.

By systematically evaluating these factors against your specific operational demands, you can select a valve that ensures long-term safety, reliability, and performance.

Summary Table:

| Selection Factor | Key Consideration | Why It Matters |

|---|---|---|

| Chemical Compatibility | Full resistance of PTFE liner to process media | Prevents corrosion and ensures system integrity |

| Pressure & Temperature | Operating conditions within valve's rated envelope | Avoids structural failure and maintains safety |

| Flow Control & Sizing | Correct Cv value and pressure drop for application | Optimizes performance and extends valve life |

| Actuation & Installation | Manual vs. automated operation; space constraints | Ensures proper fit and functional control scheme |

Need a PTFE Lined Butterfly Valve That Matches Your Demanding Application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals, liners, and custom labware, for the semiconductor, medical, laboratory, and industrial sectors. Our valves are engineered for precision, durability, and compatibility with aggressive chemicals, high-purity media, and extreme temperatures. Whether you require a standard solution or a custom-fabricated valve from prototype to high-volume orders, we ensure your system operates safely and efficiently.

Contact us today to discuss your specific requirements and let our experts help you select the perfect valve for your critical processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry