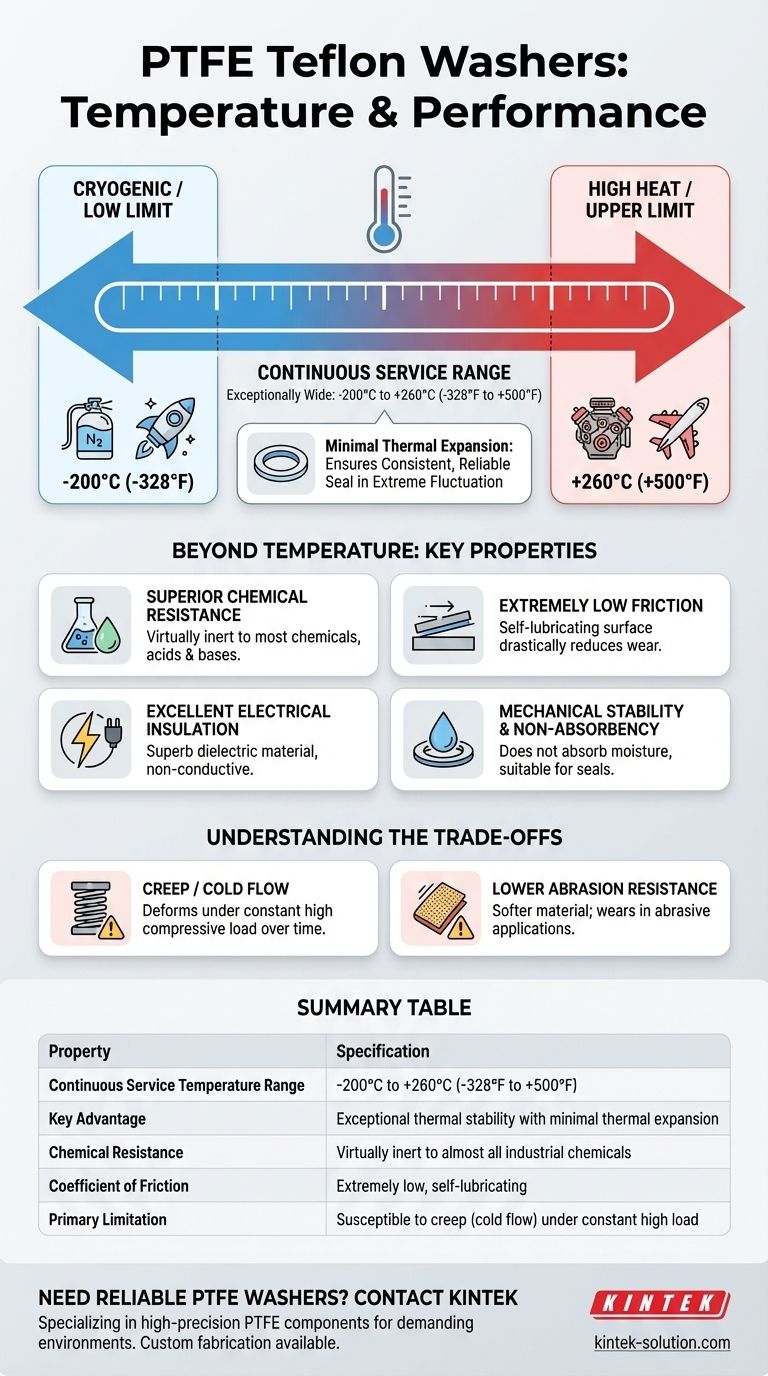

In short, the operational temperature range is exceptionally wide. PTFE Teflon washers are engineered to function effectively in continuous service from -200°C to +260°C (-328°F to +500°F). This remarkable thermal stability, combined with a near-zero rate of thermal expansion, makes it a premier material for the most demanding temperature-critical applications.

While PTFE's extreme temperature resistance is its most famous attribute, its true value comes from the combination of this stability with other unique properties like chemical inertness and low friction. Understanding this synergy is key to using it effectively.

Why PTFE Excels in Extreme Temperatures

The specified temperature range is not an arbitrary limit but is rooted in the fundamental molecular structure of Polytetrafluoroethylene (PTFE). This structure gives it unique thermal characteristics at both high and low ends of the spectrum.

The Upper Limit: +260°C (+500°F)

This figure represents the maximum continuous service temperature. At this level, the material retains its mechanical integrity and key properties without degrading.

This makes it an ideal choice for high-heat environments such as automotive engines, industrial processing equipment, and aerospace components where other polymers would fail.

The Lower Limit: -200°C (-328°F)

Unlike many materials that become brittle and fracture at cryogenic temperatures, PTFE remains flexible and functional.

This unique low-temperature durability makes it essential for applications in liquefied gas handling, scientific instrumentation, and deep-space hardware.

Minimal Thermal Expansion

A critical, and often overlooked, property is PTFE's very low coefficient of thermal expansion.

This means that as temperatures fluctuate wildly, the washer will not significantly expand or contract. This ensures a consistent, reliable seal and prevents mechanical failure.

Beyond Temperature: The Properties That Matter

Choosing a material based on a single metric is rarely sufficient. The reason PTFE is so widely trusted is that its thermal stability is complemented by a suite of other high-performance characteristics.

Superior Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals, acids, and bases. This allows it to be used in corrosive environments where both extreme temperatures and aggressive substances are present.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a self-lubricating, non-stick surface. In dynamic applications, this drastically reduces wear and energy loss between moving parts.

Excellent Electrical Insulation

As a superb dielectric material, PTFE does not conduct electricity. This makes it a critical component in high-voltage connectors and electronic insulators where thermal management is also a concern.

Mechanical Stability and Non-Absorbency

PTFE washers do not absorb moisture, which means their properties will not change in humid environments. They offer good mechanical strength suitable for sealing and gasketing applications.

Understanding the Trade-offs

No material is perfect. To use PTFE effectively, it's critical to be aware of its limitations.

Creep or "Cold Flow"

Under a constant, high compressive load, PTFE can slowly deform over time. This "cold flow" must be accounted for in high-pressure sealing applications to ensure long-term integrity.

Lower Abrasion Resistance

While it has a low-friction surface, pure PTFE is a relatively soft material. In applications with abrasive particles, it can wear more quickly than harder plastics or metals.

Not a High-Strength Structural Material

Compared to engineered plastics like PEEK or metals, PTFE has lower tensile strength and rigidity. It excels as a sealer, insulator, and bearing surface, not as a primary load-bearing component.

Making the Right Choice for Your Application

Selecting the right washer depends entirely on the specific demands of your project.

- If your primary focus is high-temperature sealing: PTFE is a top-tier choice, especially where chemical resistance and a reliable seal across temperature changes are required.

- If your primary focus is cryogenic performance: PTFE's ability to avoid embrittlement at very low temperatures makes it one of the few viable options.

- If your primary focus is a high-pressure mechanical part: You must account for PTFE's potential to creep and consider using filled PTFE grades or alternative materials for better structural integrity.

Ultimately, selecting PTFE is a decision based on leveraging its unparalleled combination of thermal, chemical, and frictional properties for your specific challenge.

Summary Table:

| Property | Specification |

|---|---|

| Continuous Service Temperature Range | -200°C to +260°C (-328°F to +500°F) |

| Key Advantage | Exceptional thermal stability with minimal thermal expansion |

| Chemical Resistance | Virtually inert to almost all industrial chemicals |

| Coefficient of Friction | Extremely low, self-lubricating |

| Primary Limitation | Susceptible to creep (cold flow) under constant high load |

Need a PTFE washer that performs reliably in extreme temperatures?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components deliver superior thermal stability, chemical resistance, and low friction.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact specifications. Let us provide the reliable sealing solution your application requires.

Contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F