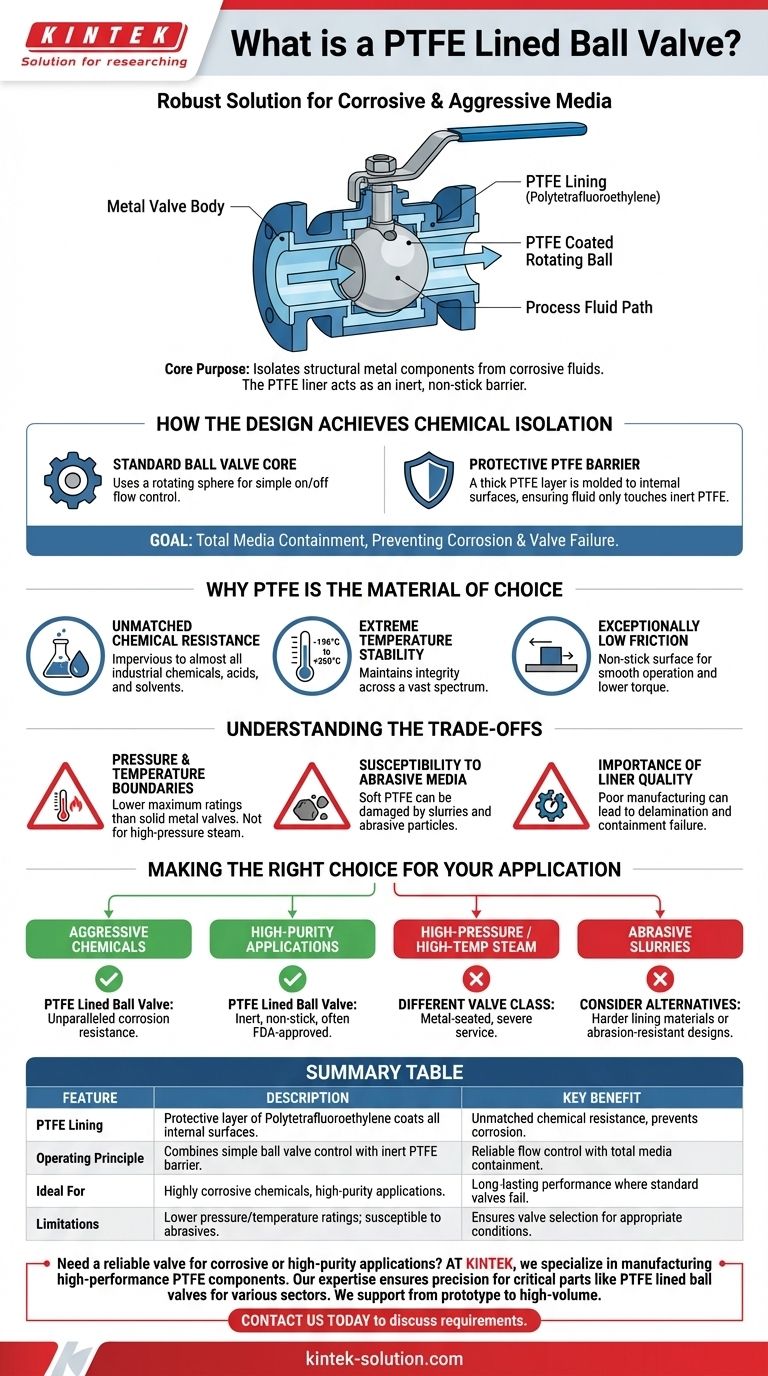

In simple terms, a PTFE lined ball valve is a standard industrial valve where all internal surfaces that contact the fluid are coated with a protective layer of Polytetrafluoroethylene (PTFE). This design combines the simple, reliable flow control of a ball valve with the exceptional chemical resistance of PTFE, creating a robust solution for handling highly corrosive or aggressive media.

The core purpose of a PTFE lined ball valve is to isolate the valve's structural metal components from the corrosive fluid it controls. The PTFE liner acts as an inert, non-stick barrier, ensuring the valve's integrity and longevity in environments that would rapidly destroy standard metal valves.

How the Design Achieves Chemical Isolation

A PTFE lined ball valve isn't a complex mechanism. Its effectiveness comes from the clever application of a unique material to a proven valve design.

The Standard Ball Valve Core

At its heart is a conventional ball valve. This valve uses a rotating sphere with a hole (or bore) through the center. When the bore is aligned with the pipe, the valve is open; when rotated 90 degrees, the solid part of the sphere blocks the flow, closing the valve.

The Protective PTFE Barrier

The critical innovation is the PTFE lining. A thick layer of PTFE is applied to the interior of the valve's body and is also molded around the rotating ball and stem. This ensures that the process fluid—be it a harsh acid, solvent, or other chemical—only ever touches the chemically inert PTFE.

The Goal: Total Media Containment

This design effectively separates the fluid from the valve's structural metal (typically carbon or stainless steel). This prevents corrosion, contamination of the fluid, and ultimately, failure of the valve itself.

Why PTFE is the Material of Choice

PTFE, widely known by the brand name Teflon®, is not just any plastic. It possesses a rare combination of properties that make it uniquely suited for this demanding role.

Unmatched Chemical Resistance

PTFE is virtually impervious to chemical attack. It is highly resistant to almost all industrial chemicals, acids, alkalis, and organic solvents, making it the default choice for the most aggressive applications.

Extreme Temperature Stability

This material maintains its integrity and performance across a vast temperature spectrum, typically rated for service from -196°C to +260°C (-320°F to +500°F).

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, making it incredibly non-stick and "slippery." This ensures the valve operates smoothly with lower torque and reduces the chance of media building up on internal surfaces.

Understanding the Trade-offs

While highly effective, PTFE lined valves are a specialized tool, and their design comes with specific limitations that are crucial to understand.

Pressure and Temperature Boundaries

While its temperature range is wide, PTFE is still a polymer, not metal. Lined valves generally have lower maximum pressure and temperature ratings compared to solid, high-performance metal-seated ball valves. They are not suitable for high-pressure steam or other extreme-temperature services.

Susceptibility to Abrasive Media

PTFE excels in corrosive environments but is a relatively soft material. It can be damaged by fluids containing hard, abrasive particles (slurries), which can wear away the lining and compromise the valve's integrity.

The Importance of Liner Quality

The manufacturing process is critical. Because PTFE has poor bonding properties, the method used to lock the liner into the valve body is paramount. A poorly manufactured liner can delaminate or fail, leading to a catastrophic breach of containment.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its capabilities to the demands of the process fluid and operating conditions.

- If your primary focus is handling aggressive chemicals: A PTFE lined ball valve is almost certainly the correct choice, offering unparalleled corrosion resistance.

- If your primary focus is high-purity applications: The inert, non-stick, and often FDA-approved nature of PTFE makes it an excellent option for food, beverage, and pharmaceutical processes.

- If your primary focus is high-pressure or high-temperature steam: You should look to a different valve class, such as a metal-seated ball valve designed for severe service.

- If your primary focus is controlling abrasive slurries: Exercise caution and consider valves with harder lining materials (like ceramic) or a design specifically intended for abrasion resistance.

Ultimately, a PTFE lined ball valve is a specialized solution designed to provide safe and reliable fluid control where standard valves would fail.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| PTFE Lining | A protective layer of Polytetrafluoroethylene coats all internal surfaces. | Provides unmatched chemical resistance and prevents corrosion. |

| Operating Principle | Combines the simple on/off control of a ball valve with the inert barrier of PTFE. | Reliable flow control with total media containment. |

| Ideal For | Highly corrosive chemicals, high-purity applications (food, pharma). | Long-lasting performance in environments that destroy metal valves. |

| Limitations | Lower pressure/temperature ratings than metal valves; susceptible to abrasive slurries. | Ensures the valve is selected for appropriate service conditions. |

Need a reliable valve for corrosive or high-purity applications?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-fabricated seals, liners, and labware. Our expertise ensures the precision and integrity of critical parts like PTFE lined ball valves for the semiconductor, medical, laboratory, and industrial sectors.

We can support your project from prototype to high-volume production. Contact us today to discuss your specific requirements and discover how our PTFE solutions can enhance your system's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does the chemical resistance of Filled PTFE compare to Virgin PTFE? A Guide to Material Selection

- What are the electrical insulation properties of PTFE caps? Superior Dielectric Performance for Demanding Applications

- How does a PTFE Lined Ball Valve function? Achieve Reliable Flow Control in Corrosive Environments

- What are the types of PTFE expansion joints available? Find the Right Fit for Your Piping System

- What are the unique properties of expanded PTFE? Unlock Superior Sealing and Filtration Performance

- What is the maximum working temperature for Teflon balls? Ensuring Safe and Reliable Performance

- What makes PTFE coatings non-stick? The Science Behind the Ultimate Slippery Surface

- How do Teflon-coated pins function in machinery? Reduce Friction and Prevent Wear