At its core, porous Polytetrafluoroethylene (PTFE) is a high-performance material used across a demanding set of industries. It is primarily applied in pharmaceuticals, automotive and aerospace, chemical processing, food and beverage manufacturing, and wastewater treatment. Its selection in these fields is driven by a unique ability to provide filtration and venting in environments where other materials would quickly fail.

The widespread adoption of porous PTFE is not accidental. It stems from a unique combination of properties: near-universal chemical inertness, high-temperature resistance, and a microporous structure that allows for precise control over what passes through it, making it an essential problem-solver in harsh industrial settings.

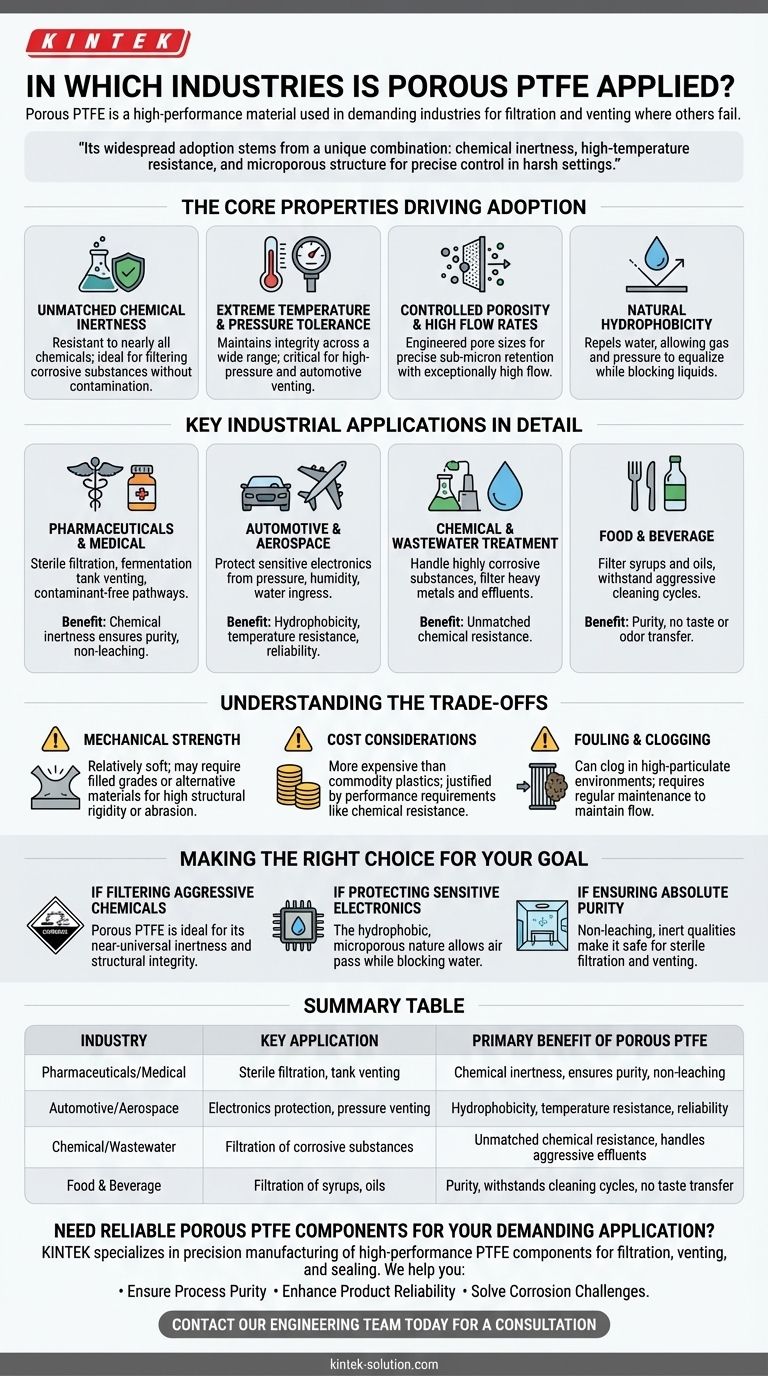

The Core Properties Driving Adoption

To understand why porous PTFE is so valued, we must look at its fundamental characteristics. These properties directly translate into performance advantages that are critical for modern industrial processes.

Unmatched Chemical Inertness

Porous PTFE is famously resistant to nearly all industrial chemicals, including aggressive acids, alkalis, and solvents. This makes it an ideal material for filtering corrosive chemicals without degrading or contaminating the process fluid.

Extreme Temperature and Pressure Tolerance

The material maintains its integrity across a very wide temperature range and can withstand high-pressure differentials. This stability is critical in applications like automotive venting near engines or in high-pressure steam lines within power plants.

Controlled Porosity and High Flow Rates

Manufacturers can engineer porous PTFE with specific pore sizes, allowing for the precise retention of particles down to the sub-micron level. Despite these small pore sizes, the material offers exceptionally high flow rates, ensuring efficient processing.

Natural Hydrophobicity

PTFE naturally repels water. This hydrophobic nature is essential for venting applications, where it allows gases and pressure to equalize while preventing water, oils, and other liquids from entering a sealed enclosure, thus protecting sensitive electronics.

Key Industrial Applications in Detail

The properties of porous PTFE directly enable its use in some of the most challenging applications within key sectors.

In Pharmaceuticals and Medical

Purity is paramount in this sector. Porous PTFE is used for sterile filtration of aggressive solvents, venting on fermentation tanks, and ensuring contaminant-free pathways for injections and medical equipment. Its chemical inertness ensures it does not leach unwanted substances into the product.

In Automotive and Aerospace

Modern vehicles and aircraft contain numerous sensitive electronic components. Porous PTFE vents are used to protect these components (like sensors and lighting enclosures) from pressure fluctuations, humidity, and direct water ingress, ensuring reliability in harsh operating conditions.

In Chemical and Wastewater Treatment

In chemical processing plants, porous PTFE filters and components handle highly corrosive substances that would destroy other materials. In wastewater treatment, it is used to filter heavy metals and aggressive chemical effluents, contributing to environmental safety and regulatory compliance.

In Food and Beverage

The need for purity and the ability to withstand aggressive cleaning cycles makes porous PTFE suitable for food processing. It is used to filter products like syrups and oils, ensuring product clarity and safety without imparting any taste or odor.

Understanding the Trade-offs

While incredibly capable, porous PTFE is not the solution for every problem. Understanding its limitations is key to making an informed decision.

Mechanical Strength

Compared to metal or certain rigid polymers, PTFE is a relatively soft material. In applications requiring high structural rigidity or abrasion resistance, a filled or modified grade of PTFE, or a different material entirely, may be necessary.

Cost Considerations

As a high-performance fluoropolymer, porous PTFE is generally more expensive than commodity plastics like polyethylene or polypropylene. Its use is typically justified when the performance requirements—such as chemical or thermal resistance—preclude the use of less expensive alternatives.

Fouling and Clogging

Like any filtration media, porous PTFE can become clogged or "fouled" over time, especially in high-particulate environments. While its non-stick surface helps mitigate this, regular maintenance or replacement schedules are often necessary to maintain optimal flow rates.

Making the Right Choice for Your Goal

Selecting the right material requires aligning its properties with the primary challenge you need to solve.

- If your primary focus is filtering aggressive chemicals or solvents: Porous PTFE is an ideal choice due to its near-universal chemical inertness and ability to maintain structural integrity.

- If your primary focus is protecting sensitive electronics from moisture: The hydrophobic and microporous nature of PTFE vents is perfect for allowing air to pass while blocking water and contaminants.

- If your primary focus is ensuring absolute purity in a medical or food-grade process: Porous PTFE's non-leaching, inert qualities make it a safe and reliable option for sterile filtration and venting.

Ultimately, choosing porous PTFE is an investment in reliability for applications where failure is not an option.

Summary Table:

| Industry | Key Application | Primary Benefit of Porous PTFE |

|---|---|---|

| Pharmaceuticals/Medical | Sterile filtration, tank venting | Chemical inertness, ensures purity, non-leaching |

| Automotive/Aerospace | Electronics protection, pressure venting | Hydrophobicity, temperature resistance, reliability |

| Chemical/Wastewater | Filtration of corrosive substances | Unmatched chemical resistance, handles aggressive effluents |

| Food & Beverage | Filtration of syrups, oils | Purity, withstands cleaning cycles, no taste transfer |

Need reliable porous PTFE components for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom porous PTFE parts for filtration, venting, and sealing. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the stringent demands of the semiconductor, medical, laboratory, and industrial sectors.

We help you:

- Ensure Process Purity: Our chemically inert PTFE components prevent contamination in sensitive pharmaceutical and food-grade processes.

- Enhance Product Reliability: Protect sensitive electronics from moisture and pressure fluctuations with our reliable venting solutions.

- Solve Corrosion Challenges: Handle aggressive chemicals confidently with components designed for long-term durability.

Let's discuss your specific requirements. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some common alternatives to Teflon sheets for heat press applications? Find the Right Protective Sheet

- How do PTFE and nylon differ in terms of water interactivity? Key Differences for Component Stability

- What factors should be considered when selecting a PTFE expansion joint? Ensure System Integrity and Safety

- What are the key benefits of PTFE energized seals for the aerospace industry? Unmatched Reliability in Extreme Environments

- What are the key advantages of PTFE gaskets? Superior Sealing for Harsh Chemical & Thermal Environments

- What is a PTFE sliding elastomeric bearing? A Guide to Managing Large Structural Movements

- What are the installation best practices for PTFE expansion bellows? Ensure Long-Term Reliability and Prevent Failure

- How do PTFE encapsulated O-rings compare to solid PTFE O-rings? Choose the Right Seal for Your Application