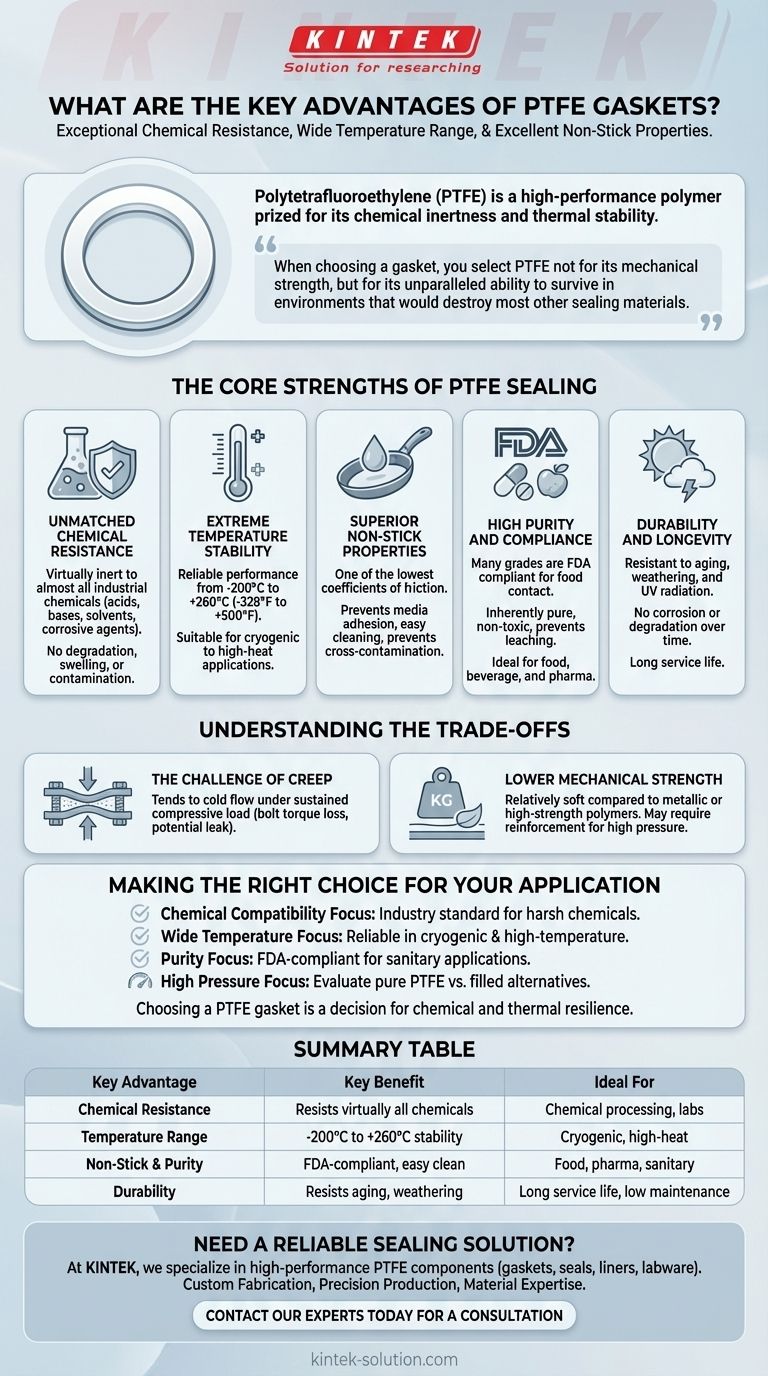

The primary advantages of PTFE gaskets are their exceptional chemical resistance, a very wide operating temperature range, and excellent non-stick properties. This unique combination makes them a superior choice for sealing applications in chemically aggressive environments or where extreme temperatures are a factor.

Polytetrafluoroethylene (PTFE) is a high-performance polymer prized for its chemical inertness and thermal stability. When choosing a gasket, you select PTFE not for its mechanical strength, but for its unparalleled ability to survive in environments that would destroy most other sealing materials.

The Core Strengths of PTFE Sealing

Understanding why PTFE is so effective requires looking at its fundamental material properties. These characteristics directly translate into reliable performance in demanding industrial, chemical, and sanitary applications.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals. This includes strong acids, bases, solvents, and corrosive agents.

This property ensures the gasket will not degrade, swell, or contaminate the process media, preserving both the seal's integrity and the purity of the product.

Extreme Temperature Stability

PTFE gaskets perform reliably across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This makes them suitable for everything from cryogenic applications to high-heat industrial processes, without becoming brittle or losing their sealing capabilities.

Superior Non-Stick Properties

PTFE has one of the lowest coefficients of friction of any solid material, giving it excellent non-stick or "release" characteristics.

This prevents process media from adhering to the gasket surface, which is critical for ensuring easy cleaning, preventing cross-contamination, and reducing residue buildup in piping systems.

High Purity and Compliance

Many grades of PTFE are compliant with FDA regulations for food contact. The material is inherently pure and does not contain contaminants that can leach into the process media.

This makes it an essential choice for applications in the food, beverage, and pharmaceutical industries where hygiene and non-toxicity are non-negotiable.

Durability and Longevity

PTFE is highly resistant to aging, weathering, and UV radiation. It does not corrode or degrade over time when exposed to the elements.

This inherent stability contributes to a long service life, reducing the need for frequent replacement and lowering overall maintenance costs.

Understanding the Trade-offs

While its advantages are significant, no material is perfect. A true understanding of PTFE requires acknowledging its mechanical limitations, which is crucial for proper application.

The Challenge of Creep

The most significant drawback of pure PTFE is its tendency to creep or exhibit cold flow.

This means that under sustained compressive load (like a bolted flange), the material can slowly deform and flow out of the seal area. This can lead to a loss of bolt torque and, eventually, a potential leak.

Lower Mechanical Strength

Compared to metallic or other high-strength polymer gaskets, pure PTFE is a relatively soft material.

It may not be suitable for extremely high-pressure applications without reinforcement. To counteract creep and improve strength, PTFE is often blended with fillers like glass, carbon, or graphite.

Making the Right Choice for Your Application

Selecting the right gasket material requires matching its properties to the demands of the service environment.

- If your primary focus is chemical compatibility: PTFE is the industry standard for sealing harsh acids, bases, and solvents.

- If your primary focus is a wide temperature range: PTFE provides a reliable seal in both cryogenic and high-temperature conditions.

- If your primary focus is purity and hygiene: FDA-compliant PTFE is the definitive choice for sanitary applications in food, beverage, and pharma.

- If your primary focus is high mechanical pressure: Carefully evaluate if pure PTFE is sufficient, or if a filled PTFE or alternative material is needed to prevent creep.

Ultimately, choosing a PTFE gasket is a decision for chemical and thermal resilience where other materials would fail.

Summary Table:

| Key Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Resists virtually all industrial chemicals, acids, and solvents | Chemical processing, labs |

| Temperature Range | Stable performance from -200°C to +260°C | Cryogenic to high-heat applications |

| Non-Stick & Purity | FDA-compliant, prevents contamination, easy to clean | Food, pharma, sanitary industries |

| Durability | Resists aging, weathering, and UV radiation | Long service life, low maintenance |

Need a reliable sealing solution for demanding conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision gaskets, seals, liners, and labware. Our expertise ensures your equipment operates flawlessly in the most aggressive chemical and thermal environments.

We serve the semiconductor, medical, laboratory, and industrial sectors with:

- Custom Fabrication: From prototypes to high-volume orders

- Precision Production: Consistent quality for critical applications

- Material Expertise: Right PTFE formulation for your specific needs

Let us help you solve your toughest sealing challenges. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability