The primary difference lies in their mechanical properties, not their chemical resistance. While both solid PTFE and PTFE encapsulated O-rings provide elite resistance to chemicals and extreme temperatures, the encapsulated version incorporates an elastomeric core. This core gives it the vital elasticity and memory needed for reliable sealing, a property that rigid, solid PTFE O-rings inherently lack.

The choice between a solid and an encapsulated PTFE O-ring is fundamentally a choice between a rigid gasket and a resilient seal. An encapsulated O-ring combines the chemical inertness of PTFE with the physical performance of rubber, making it suitable for a much broader range of dynamic and critical sealing applications.

Understanding the Fundamental Designs

To select the right component, you must first understand how their construction dictates their function. The two products serve very different engineering needs despite their similar material names.

Solid PTFE O-Rings: The Inert Barrier

A solid PTFE O-ring is machined from a single, homogenous piece of Polytetrafluoroethylene. It acts as a static gasket, creating a simple physical barrier.

Its strengths are significant: it is virtually immune to chemical attack, has an exceptionally wide operating temperature range (from -250°C to +250°C), and possesses an extremely low coefficient of friction.

However, its defining weakness is its lack of elasticity. PTFE is a rigid plastic; when compressed, it deforms permanently and does not spring back to its original shape. This phenomenon is known as compression set.

Encapsulated O-Rings: The Hybrid Solution

An encapsulated O-ring is a composite seal. It consists of a tough, seamless outer jacket of PTFE (or a similar fluoropolymer like FEP/PFA) that completely encloses a core of high-performance rubber.

This design brilliantly merges the strengths of two material classes. The outer PTFE jacket provides the chemically inert, low-friction contact surface, while the inner elastomeric core provides the flexibility and "push back" required for a positive seal.

The two most common core materials are Silicone and Viton® (FKM), each offering a different performance profile.

How the Core Determines Sealing Performance

The presence of an energizing core is the critical advantage of the encapsulated design. Without this internal pressure, a seal can easily fail under real-world conditions.

The Critical Role of Elasticity

An effective seal must constantly exert an outward force against the surfaces it's sealing. This resilience allows it to compensate for surface imperfections, pressure fluctuations, and thermal expansion or contraction.

Solid PTFE cannot do this. Once compressed, it stays compressed. Any minor shift or vibration in the assembly can create a leak path.

The Silicone Core Option

A silicone core is an excellent general-purpose choice, prized for its wide temperature range that complements the PTFE jacket. It maintains its flexibility at very low temperatures and performs well at high temperatures.

The Viton® (FKM) Core Option

A Viton® (fluoroelastomer) core provides superior resistance to compression set compared to silicone. This makes it the preferred choice for higher-pressure applications or where maintaining a consistent sealing force over a long lifetime is absolutely critical.

Understanding the Trade-offs and Limitations

Choosing the right seal requires an objective look at the potential downsides and failure modes of each option.

The Inflexibility of Solid PTFE

The primary drawback of solid PTFE is its poor resistance to compression set. It is only suitable for completely static, face-seal applications where the sealing surfaces are perfectly machined and will experience no movement, vibration, or temperature cycling. Using it in a dynamic or non-ideal static application will almost certainly result in a leak.

The Resilience of Encapsulated Rings

The key benefit of an encapsulated O-ring is its elasticity and resistance to compression set. This allows it to function as a true O-ring, maintaining a live, resilient seal in both static and light dynamic applications across a wide range of harsh environments. It prevents premature seal failure caused by aggressive fluids or gases.

Cost and Installation Considerations

Encapsulated O-rings are more complex to manufacture and are therefore more expensive than solid PTFE rings. Furthermore, care must be taken during installation to avoid nicking or scratching the thin PTFE jacket, as this would compromise the seal's chemical resistance by exposing the vulnerable core.

Making the Right Choice for Your Application

Your final decision should be based entirely on the mechanical demands of your sealing environment, not just the chemical compatibility.

- If your primary focus is a static face seal in a low-pressure, chemically aggressive environment: A solid PTFE O-ring can serve as a cost-effective and suitably inert gasket.

- If your application involves pressure, thermal cycles, vibration, or any potential joint movement: The elasticity of a PTFE encapsulated O-ring is essential for maintaining a long-term, leak-free seal.

- If you need the mechanical performance of a rubber O-ring but the media is too corrosive for any standard elastomer: A PTFE encapsulated O-ring is the ideal solution, providing a chemically impervious shield for a resilient core.

Ultimately, understanding the fundamental difference between a static gasket and a dynamic seal will empower you to select the component that ensures reliability for your specific goal.

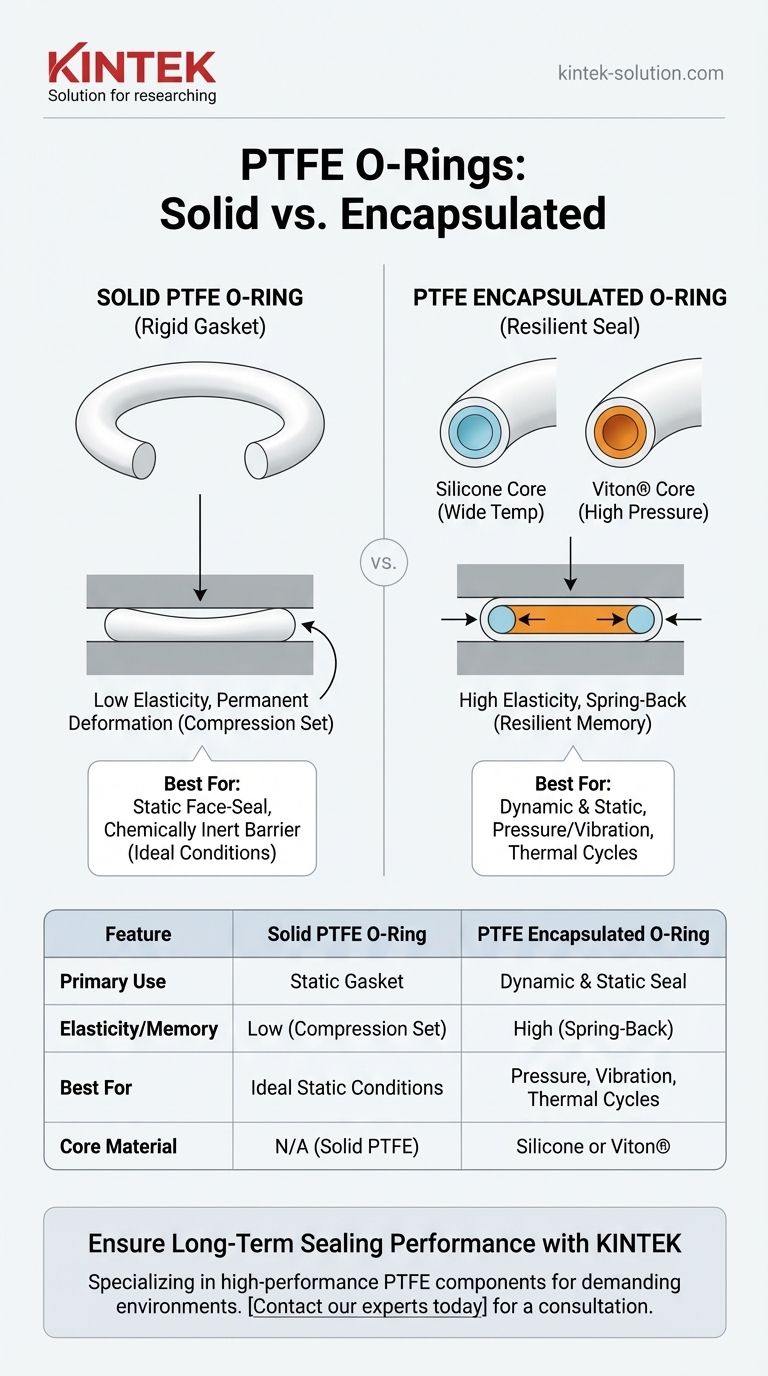

Summary Table:

| Feature | Solid PTFE O-Ring | PTFE Encapsulated O-Ring |

|---|---|---|

| Primary Use | Static face-seal gasket | Dynamic & static resilient seal |

| Elasticity / Memory | Low (Prone to compression set) | High (Resilient, spring-back) |

| Best For | Chemically inert barrier in ideal, static conditions | Applications with pressure, vibration, or thermal cycles |

| Core Material | N/A (Solid PTFE) | Silicone (wide temp) or Viton® (high pressure) |

Ensure Long-Term Sealing Performance with KINTEK

Selecting the right O-ring is critical for the reliability of your equipment. Whether you need the chemical inertness of a solid PTFE gasket or the resilient, dynamic sealing of an encapsulated O-ring, KINTEK has the expertise and manufacturing precision to deliver.

We specialize in custom fabricating high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we ensure every part meets your exact specifications for demanding environments.

Let's discuss your application requirements and find the perfect sealing solution. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions