In the high-stakes world of aerospace, component failure is not an option. PTFE energized seals are a cornerstone of system reliability, providing a unique combination of material resilience and mechanical design. They offer exceptional performance across vast temperature and pressure ranges, resist aggressive chemicals, and maintain integrity in the vacuum of space, making them indispensable for critical flight systems.

The true advantage of a PTFE energized seal isn't just the material itself, but the synergy between the durable PTFE jacket and its internal spring. This combination creates an "active" seal that constantly adapts to pressure, temperature, and wear, ensuring a reliable barrier where conventional seals would inevitably fail.

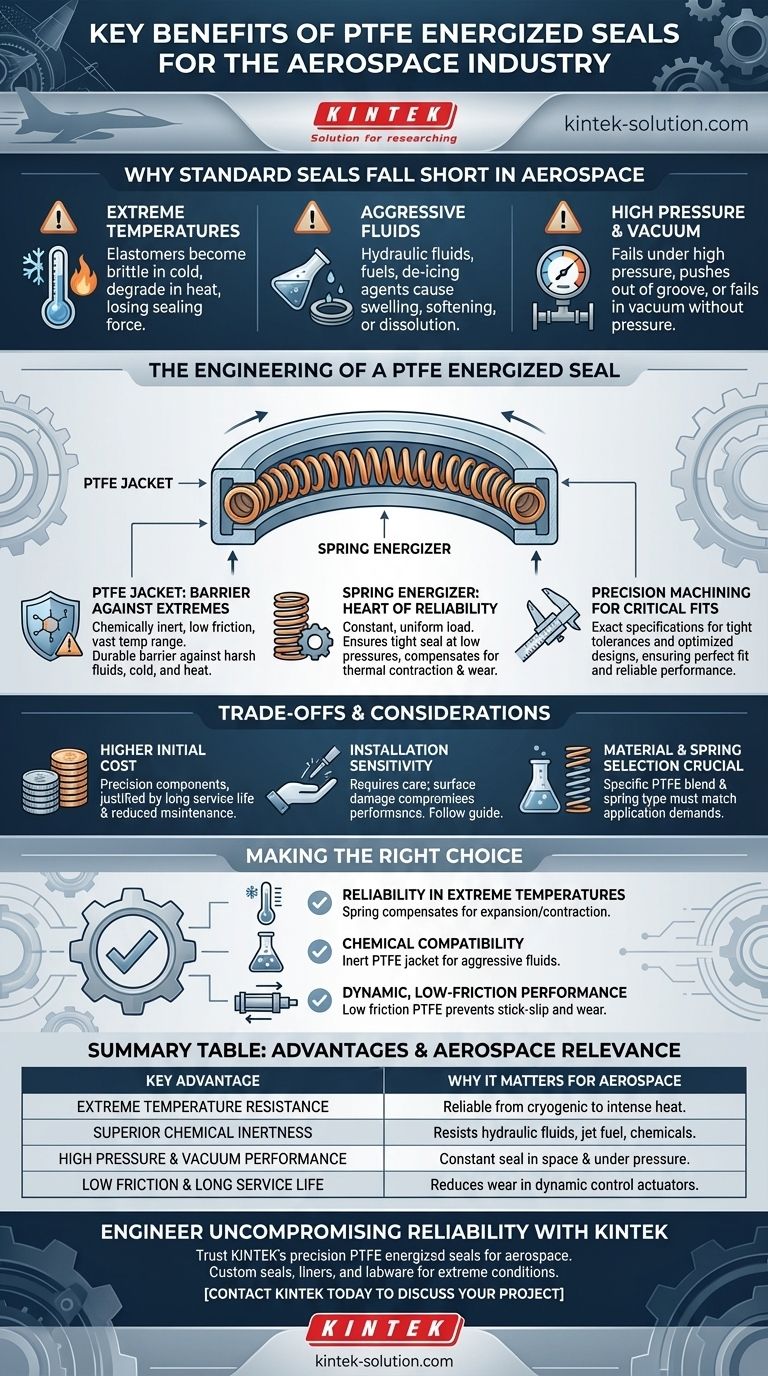

Why Standard Seals Fall Short in Aerospace

Traditional elastomeric seals, like O-rings, are often inadequate for the severe demands of aerospace and defense applications. The operational environment pushes materials well beyond their normal limits.

The Challenge of Extreme Temperatures

Aircraft operate in a world of thermal extremes, from cryogenic temperatures at high altitudes to the intense heat generated by engines and friction. Standard elastomers become brittle in the cold and degrade in the heat, causing them to lose their sealing force and fail.

The Problem of Aggressive Fluids

Aerospace systems rely on a host of aggressive chemicals, including hydraulic fluids, jet fuel, and de-icing agents. These substances can cause many sealing materials to swell, soften, or dissolve, leading to leaks and system contamination.

The Dual Threat of High Pressure and Vacuum

Seals must perform flawlessly under high-pressure hydraulic actuation and in the near-vacuum conditions of outer space. A standard seal may be pushed out of its groove under pressure or fail to seal at all when no pressure is present to energize it.

The Engineering of a PTFE Energized Seal

The design of a spring-energized seal directly addresses the failures of conventional seals. It is a two-part system where each component solves a specific problem.

The PTFE Jacket: A Barrier Against Extremes

The outer seal jacket is precision-machined from a Polytetrafluoroethylene (PTFE) compound. This material provides the primary benefits of chemical inertness, an extremely low coefficient of friction, and a vast operating temperature range. It forms a durable barrier that won't degrade when exposed to harsh fluids or extreme cold and heat.

The Spring Energizer: The Heart of Reliability

Inside the PTFE jacket sits a corrosion-resistant metal spring. This is the "energizer" and it provides a constant, uniform load against the sealing surfaces. This mechanical force ensures a tight seal even at very low pressures or when the PTFE jacket contracts in extreme cold, a condition where a standard O-ring would leak. It also compensates for material wear over the seal's long lifespan.

Precision Machining for Critical Fits

Unlike molded elastomeric seals, PTFE energized seals are machined to exact specifications. This allows for tight tolerances and optimized designs for specific applications, from landing gear struts to fuel system valves, ensuring a perfect fit and reliable performance.

Understanding the Trade-offs and Considerations

While highly effective, PTFE energized seals are a specialized solution. Understanding their limitations is key to proper application.

Higher Initial Cost

These are high-performance, precision-engineered components. Their initial cost is significantly higher than that of a simple elastomeric O-ring. However, this cost is often justified by their reliability and long service life, which prevents costly maintenance and system failures.

Installation Sensitivity

The rigidity of the PTFE jacket and the precision nature of the seal mean that installation requires care. Scratches on the sealing surface or improper handling can compromise performance. Following manufacturer guidelines for installation is critical.

Material and Spring Selection is Crucial

"PTFE energized seal" is a category, not a single product. The specific blend of the PTFE compound and the type of metal spring must be carefully selected based on the application's unique chemical, temperature, and pressure demands. A mismatch can lead to suboptimal performance.

Making the Right Choice for Your System

Choosing a sealing solution requires a clear understanding of your primary engineering goal. The design of a PTFE energized seal offers distinct advantages for different priorities.

- If your primary focus is reliability in extreme temperatures: The spring energizer is crucial as it compensates for thermal expansion and contraction, maintaining a seal where elastomers would fail.

- If your primary focus is chemical compatibility: The inherent inertness of the PTFE jacket makes it the default choice for systems exposed to aggressive hydraulic fluids, fuels, and corrosive agents.

- If your primary focus is dynamic, low-friction performance: The exceptionally low coefficient of friction of PTFE prevents stick-slip behavior and reduces wear in critical moving components like flight control actuators.

By understanding this synergy of material and mechanics, engineers can confidently specify a sealing solution built for the uncompromising demands of aerospace.

Summary Table:

| Key Advantage | Why It Matters for Aerospace |

|---|---|

| Extreme Temperature Resistance | Performs reliably from cryogenic cold to intense heat, where standard seals fail. |

| Superior Chemical Inertness | Resists degradation from hydraulic fluids, jet fuel, and other aggressive chemicals. |

| High Pressure & Vacuum Performance | The internal spring ensures a constant seal under high pressure and in the vacuum of space. |

| Low Friction & Long Service Life | Reduces wear in dynamic applications like flight control actuators, extending component life. |

Engineer Uncompromising Reliability with KINTEK

When failure is not an option, trust the precision of KINTEK's PTFE energized seals. We specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your aerospace systems are protected against extreme temperatures, aggressive chemicals, and vacuum conditions.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, tailored to your specific application requirements.

Contact KINTEK today to discuss your project and discover how our sealing solutions can enhance the safety and performance of your critical systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining