To ensure a successful installation of PTFE expansion bellows, you must focus on three critical actions: guaranteeing perfect pipeline alignment, adhering strictly to the manufacturer's fastener torque specifications, and providing adequate clearance for movement. These steps prevent the bellow from being installed in a stressed state, which is the primary cause of premature wear and catastrophic failure.

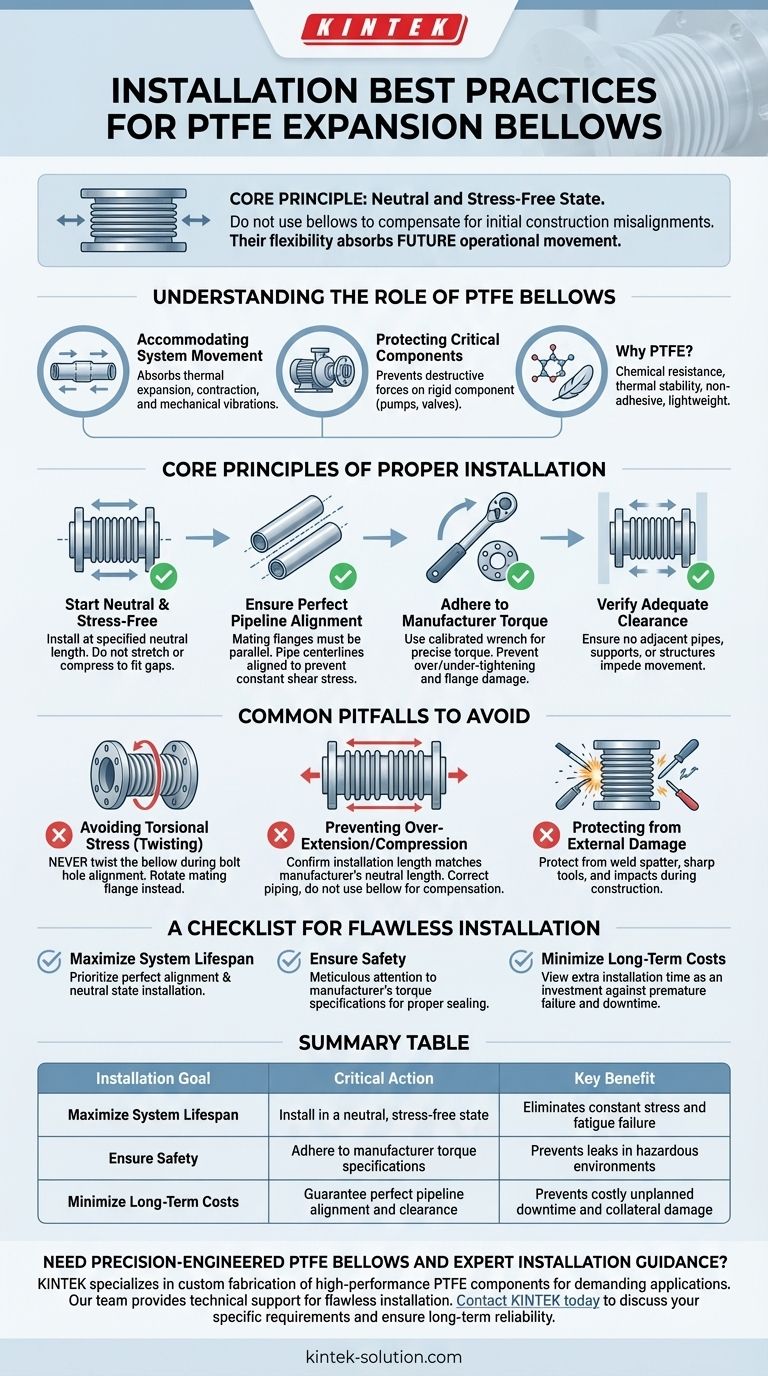

The core principle of a successful installation is to mount the bellow in a perfectly neutral and stress-free state. Its inherent flexibility is meant to absorb future operational movement, not to compensate for initial construction misalignments.

Understanding the Role of PTFE Bellows

PTFE expansion bellows are not just simple connectors; they are dynamic components engineered to protect the integrity of your entire piping system. Understanding their function clarifies why precise installation is non-negotiable.

Accommodating System Movement

The primary role of an expansion bellow is to absorb movement. This includes the thermal expansion and contraction of pipes as temperatures change, as well as mechanical vibrations from pumps, engines, or other equipment.

Protecting Critical Components

By absorbing this stress and movement, the bellow prevents destructive forces from being transferred to more rigid and expensive components like pump nozzles, vessel flanges, and valve bodies.

Why PTFE is the Material of Choice

PTFE offers tremendous chemical resistance, thermal stability, and a non-adhesive surface. Its lightweight nature also makes it significantly easier to handle and install compared to heavy, rigid metal bellows, reducing labor costs and complexity.

Core Principles of Proper Installation

A flawless installation revolves around preventing the introduction of any unintended stress into the bellow. Every best practice is designed to achieve this goal.

Start with a Neutral, Stress-Free State

The bellow should be installed at its specified neutral length, without being stretched or compressed to fit the gap between pipes. Using the bellow to pull pipes into alignment will impose a constant stress, drastically shortening its service life.

Ensure Perfect Pipeline Alignment

The mating flanges must be parallel, and the pipe centerlines must be aligned. Misalignment forces the bellow into a constant state of deflection, creating a shear stress that will eventually lead to fatigue failure at the cuff or convolutions.

Adhere to Manufacturer Torque Specifications

Each bellow has a precise torque value for its fasteners. Over-tightening can crack the PTFE flare or damage the flange, while under-tightening will fail to create a proper seal, resulting in leaks. Always use a calibrated torque wrench.

Verify Adequate Clearance

The bellow needs physical space to move in all required directions (axially and laterally). Ensure no adjacent pipes, supports, or structures will impede its movement once the system is operational.

Common Pitfalls and How to Avoid Them

Even with the best intentions, simple oversights during installation can compromise the bellow. Awareness of these common mistakes is the first step in preventing them.

Avoiding Torsional Stress (Twisting)

A bellow is not designed to handle twisting. When aligning bolt holes, never twist the bellow itself. Instead, rotate the mating flange before inserting bolts. Torsional stress is highly destructive to the convoluted structure.

Preventing Over-Extension or Compression

Always confirm the installation length matches the manufacturer's neutral length specification. If the gap is too large or too small, correct the piping. Do not use the bellow to compensate for piping fabrication errors.

Protecting from External Damage

During construction and welding, the bellow must be protected. Weld spatter can burn holes in the thin PTFE material, and sharp tools or impacts can easily cause damage that leads to failure under pressure.

A Checklist for Flawless Installation

Use this checklist to align your installation procedure with the specific goals of your system, ensuring you maximize the value and lifespan of the component.

- If your primary focus is maximizing system lifespan: Prioritize perfect alignment and installing the bellow in a completely neutral state. This eliminates the constant stress that is the leading cause of fatigue failure.

- If your primary focus is ensuring safety in hazardous environments: Pay meticulous attention to the manufacturer's torque specifications. A proper, even seal is the single most important factor in preventing leaks of corrosive or dangerous chemicals.

- If your primary focus is minimizing long-term costs: View the extra time spent on correct installation as an investment. Proper installation prevents premature failure, which in turn eliminates costly unplanned downtime, collateral damage, and replacement expenses.

Ultimately, a few moments of careful attention to detail during installation will ensure the PTFE bellow performs its protective function reliably for years to come.

Summary Table:

| Installation Goal | Critical Action | Key Benefit |

|---|---|---|

| Maximize System Lifespan | Install in a neutral, stress-free state | Eliminates constant stress and fatigue failure |

| Ensure Safety | Adhere to manufacturer torque specifications | Prevents leaks in hazardous or corrosive environments |

| Minimize Long-Term Costs | Guarantee perfect pipeline alignment and clearance | Prevents costly unplanned downtime and collateral damage |

Need precision-engineered PTFE bellows and expert installation guidance?

KINTEK specializes in the custom fabrication of high-performance PTFE components, including expansion bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our components are manufactured with the precision required for demanding applications, and our team can provide the technical support you need for a flawless installation.

Contact KINTEK today to discuss your specific requirements, from prototypes to high-volume orders, and ensure the long-term reliability of your piping system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications