In short, PTFE tri clamp gaskets are predominantly used in industries where purity, sterility, and chemical resistance are non-negotiable. The core users are the pharmaceutical, biotechnology, food and beverage, and chemical processing industries, which rely on these gaskets to maintain the integrity of their sanitary and high-purity fluid handling systems.

The decision to use a PTFE tri clamp gasket is driven by a simple equation: the unparalleled chemical inertness and purity of the PTFE material combined with the hygienic, easy-to-clean design of a tri clamp fitting. This combination is essential for preventing contamination in sensitive processes.

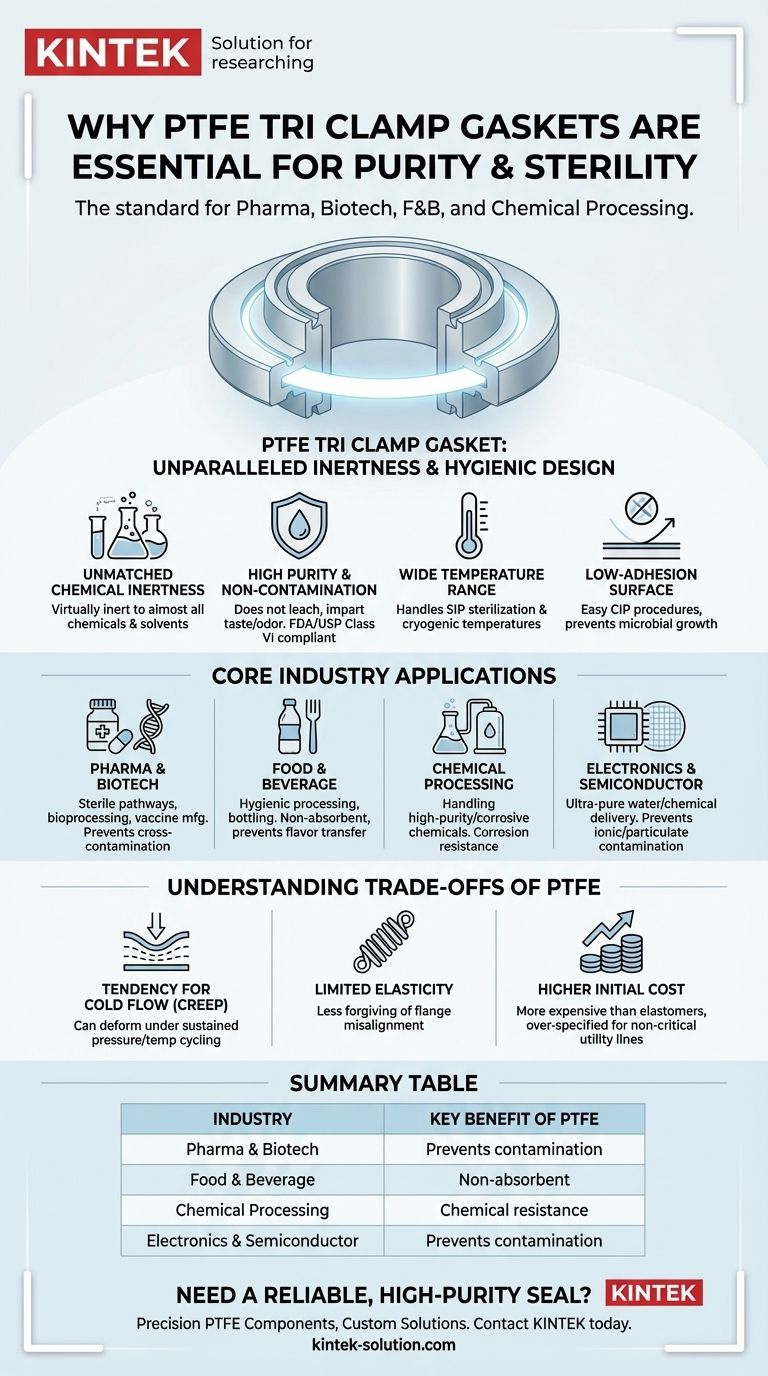

Why PTFE is the Material of Choice for Sanitary Systems

The selection of a gasket material is a critical decision in process engineering. PTFE (Polytetrafluoroethylene) possesses a unique set of properties that make it the gold standard for many demanding applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it the ideal choice for lines that handle aggressive substances or undergo rigorous chemical sterilization cycles.

High Purity and Non-Contamination

The material is inherently pure and does not leach contaminants or impart taste, color, or odor to the product. This is a critical requirement in pharmaceutical manufacturing and food processing, where product integrity is paramount.

Wide Temperature Range

PTFE gaskets perform reliably across a broad temperature spectrum. They can handle high-temperature processes like Steam-in-Place (SIP) sterilization as well as cryogenic applications without becoming brittle.

Low-Adhesion Surface

Often referred to by its trade name, Teflon, PTFE has an extremely low-friction, non-stick surface. This property prevents process media from adhering to the gasket, which simplifies Clean-in-Place (CIP) procedures and minimizes the risk of microbial growth.

Core Industry Applications

While many industries use PTFE in various forms, the tri clamp gasket is specifically designed for sanitary connections, which narrows its primary use cases to the following sectors.

Pharmaceutical & Biotechnology

In these fields, preventing cross-contamination is the highest priority. PTFE tri clamp gaskets are used in bioprocessing, vaccine manufacturing, and pharmaceutical synthesis to ensure sterile pathways and meet strict regulatory standards like USP Class VI.

Food & Beverage

From dairy processing to beverage bottling, maintaining hygienic conditions is essential. PTFE gaskets provide a cleanable, non-absorbent seal that complies with FDA regulations and prevents flavor transfer between different product batches.

Chemical Processing

For manufacturing high-purity chemicals, specialty solvents, or sensitive compounds, PTFE provides the necessary resistance to corrosion. It ensures that the final product is not contaminated by reactions with sealing components.

Electronics and Semiconductor

The manufacturing of semiconductors requires ultra-pure water and highly corrosive chemicals. PTFE gaskets are used in the fluid delivery systems for these facilities to prevent any ionic or particulate contamination that could ruin a silicon wafer.

Understanding the Trade-offs of PTFE

Despite its significant advantages, PTFE is not a universal solution. Understanding its limitations is key to successful implementation.

Tendency for Cold Flow (Creep)

PTFE is a softer material that can deform or "creep" over time, especially under sustained bolt pressure and temperature cycling. This can lead to a loss of seal tightness, requiring periodic re-torquing or the use of specially designed, mechanically stabilized gaskets.

Limited Elasticity

Compared to rubber elastomers like EPDM or Silicone, PTFE is relatively rigid. It has less "memory" and is less forgiving of flange misalignment or surface imperfections, demanding more precise installation to achieve a reliable seal.

Higher Initial Cost

PTFE is generally a more expensive material than common elastomers. While its performance and longevity often justify the cost in critical applications, it may be over-specified for less demanding utility lines.

Making the Right Choice for Your Goal

Selecting the correct gasket requires balancing performance requirements with material properties and cost.

- If your primary focus is absolute product purity and sterility: PTFE is the industry standard for pharmaceutical and bioprocessing applications due to its unmatched inertness.

- If your primary focus is handling aggressive or corrosive chemicals: PTFE's broad chemical resistance makes it the safest and most reliable choice for demanding chemical processing lines.

- If your primary focus is general-purpose food production with moderate temperatures: A high-quality elastomer like EPDM may be a more cost-effective and resilient option, but PTFE is superior for processes involving aggressive cleaning agents or oily products.

Ultimately, choosing the right gasket is a critical engineering decision that directly impacts product safety, purity, and operational reliability.

Summary Table:

| Industry | Primary Use Case | Key Benefit of PTFE |

|---|---|---|

| Pharmaceutical & Biotechnology | Sterile fluid pathways, bioprocessing | Prevents contamination, USP Class VI compliant |

| Food & Beverage | Hygienic processing, bottling lines | Non-absorbent, prevents flavor transfer, FDA compliant |

| Chemical Processing | Handling corrosive or high-purity chemicals | Unmatched chemical inertness and resistance |

| Electronics & Semiconductor | Ultra-pure water and chemical delivery | Prevents ionic/particulate contamination |

Need a reliable, high-purity seal for your critical process?

At KINTEK, we specialize in manufacturing precision PTFE components, including tri clamp gaskets, seals, liners, and custom labware. We understand the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems maintain integrity, prevent contamination, and withstand aggressive chemicals.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss your application and get a quote for a solution built for reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does the chemical resistance of NBR compare to PTFE in butterfly valve seats? Select the Right Material for Your Media.

- What industries benefit from the high-temperature and high-pressure resistance of PTFE bellows? Ensure System Integrity in Demanding Applications

- How does the working process affect PTFE Teflon O-rings? It Dictates Sealing Performance & Lifespan

- What is the coefficient of friction for PTFE O-Rings and why is it beneficial? Achieve Smooth, Low-Friction Performance

- How does the flexibility of PTFE gaskets contribute to their versatility? Sealing Imperfect Surfaces with Ease

- What general maintenance practices can extend the lifespan of PTFE gaskets? Optimize Selection, Installation, and Monitoring

- What factors should be considered when selecting a PTFE lip seal? Optimize Your Sealing System for Reliability

- What are some common fillers used in PTFE seal materials? Enhance Performance for Your Application