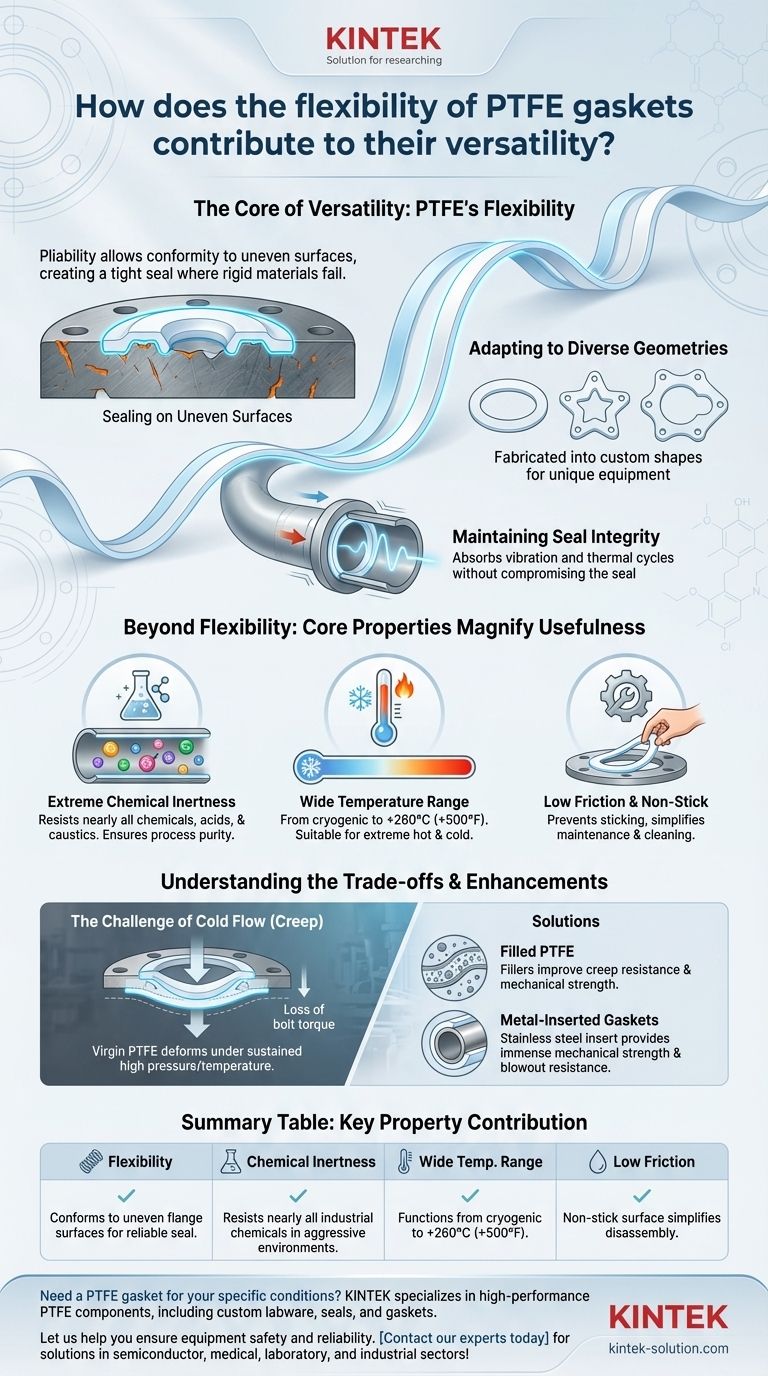

The flexibility of a PTFE gasket is the direct source of its versatility. This physical pliability allows the material to conform perfectly to irregular or uneven flange surfaces, creating a tight, reliable seal where more rigid materials would fail. This core attribute, combined with PTFE's inherent chemical and thermal resistance, makes it an exceptionally adaptable solution for countless industrial applications.

The true value of PTFE's flexibility is its ability to ensure seal integrity in real-world conditions where surfaces are rarely perfect. This adaptability is magnified by its elite chemical and thermal properties, making it a cornerstone material for demanding sealing challenges.

The Foundation of Versatility: Conforming to Reality

The primary advantage of PTFE's flexibility is its capacity to compensate for imperfections in a sealing system. Industrial equipment rarely operates in a perfect, theoretical state.

Sealing on Uneven Surfaces

Industrial flanges can become scratched, warped, or corroded over time. PTFE's pliable nature allows it to flow into these microscopic peaks and valleys, creating a continuous, leak-proof barrier.

A rigid gasket, in contrast, can only make contact with the highest points of an uneven surface, leaving gaps that inevitably lead to leaks.

Adapting to Diverse Geometries

Sealing applications are not limited to standard circular pipes. PTFE can be easily fabricated into a vast array of custom shapes and sizes to fit unique equipment designs.

This adaptability ensures that its superior sealing properties can be applied to virtually any configuration, from complex machinery to non-standard vessel lids.

Maintaining Seal Integrity

The flexibility of PTFE helps absorb minor vibrations and thermal expansion or contraction in a system without compromising the seal.

This dynamic response is critical for maintaining long-term safety and reliability, preventing leaks that could otherwise be caused by normal operational stresses.

Beyond Flexibility: Core Properties that Magnify Its Usefulness

While flexibility provides the mechanism for a good seal, it is PTFE's other intrinsic properties that unlock its use in such a wide range of demanding environments.

Extreme Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and caustics. This means its flexibility is not compromised by chemical attack, making it ideal for the chemical processing, pharmaceutical, and food and beverage industries.

Its non-contaminating and non-wetting nature ensures process purity.

Wide Temperature Range

A material's flexibility is useless if it becomes brittle or melts. PTFE maintains its pliability and sealing capability from cryogenic temperatures up to +260°C (+500°F).

This enormous operational window allows a single material to be specified for applications involving extreme cold and high heat.

Low Friction and Non-Stick Surface

PTFE's famously low coefficient of friction means it will not stick to flange surfaces. This "non-stick" quality simplifies disassembly and cleaning during maintenance, preventing gasket residue and flange damage.

Understanding the Trade-offs and Enhancements

While remarkably versatile, standard PTFE is not without limitations. Understanding these trade-offs is key to selecting the right variant for a specific application.

The Challenge of Cold Flow

The primary limitation of pure, or "virgin," PTFE is its tendency to cold flow, also known as creep. Under sustained high pressure and temperature, the material can slowly deform and be squeezed out of the flange.

This can lead to a loss of bolt torque and, eventually, a failed seal.

The Role of Fillers

To combat cold flow and improve mechanical strength, PTFE is often blended with filler materials like glass, carbon, or silica. These filled PTFE gaskets offer significantly improved resistance to creep and wear.

The trade-off is that fillers can sometimes slightly reduce the gasket's overall chemical resistance compared to pure PTFE.

Metal-Inserted Gaskets

For the most demanding high-pressure and high-temperature applications, metal-inserted PTFE gaskets provide the ultimate solution.

A stainless steel insert provides immense mechanical strength and blowout resistance, while the surrounding PTFE provides the conformable seal and chemical inertness. This composite design leverages the best properties of both materials.

Making the Right Choice for Your Application

Selecting the correct PTFE gasket requires matching its properties to your operational demands. Your primary goal will dictate the best choice.

- If your primary focus is sealing uneven or worn flange surfaces: The inherent flexibility of standard virgin PTFE makes it an excellent choice for creating a positive seal.

- If your primary focus is high-pressure or high-temperature service: A filled PTFE or a metal-inserted PTFE gasket is necessary to mitigate the risk of cold flow and ensure long-term seal integrity.

- If your primary focus is chemical purity or sanitary applications: Virgin (unfilled) PTFE is the ideal choice due to its non-contaminating and non-wetting properties.

By understanding how flexibility works in concert with its other unique traits, you can select the right PTFE gasket to ensure the safety and reliability of your equipment.

Summary Table:

| Key Property | Contribution to Versatility |

|---|---|

| Flexibility | Conforms to uneven flange surfaces, ensuring a reliable seal where rigid materials fail. |

| Chemical Inertness | Resists nearly all industrial chemicals, maintaining seal integrity in aggressive environments. |

| Wide Temp. Range | Functions from cryogenic to +260°C (+500°F), making it suitable for extreme applications. |

| Low Friction | Non-stick surface simplifies disassembly and prevents flange damage during maintenance. |

Need a PTFE gasket that seals perfectly under your specific conditions?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, gaskets, liners, and custom labware. Whether you require the superior chemical purity of virgin PTFE for sanitary applications, the enhanced creep resistance of filled PTFE for high-pressure service, or the robust strength of metal-inserted designs, we provide custom fabrication from prototypes to high-volume orders.

Let us help you ensure the safety and reliability of your equipment. Contact our experts today for a solution tailored to your needs in the semiconductor, medical, laboratory, or industrial sectors!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments