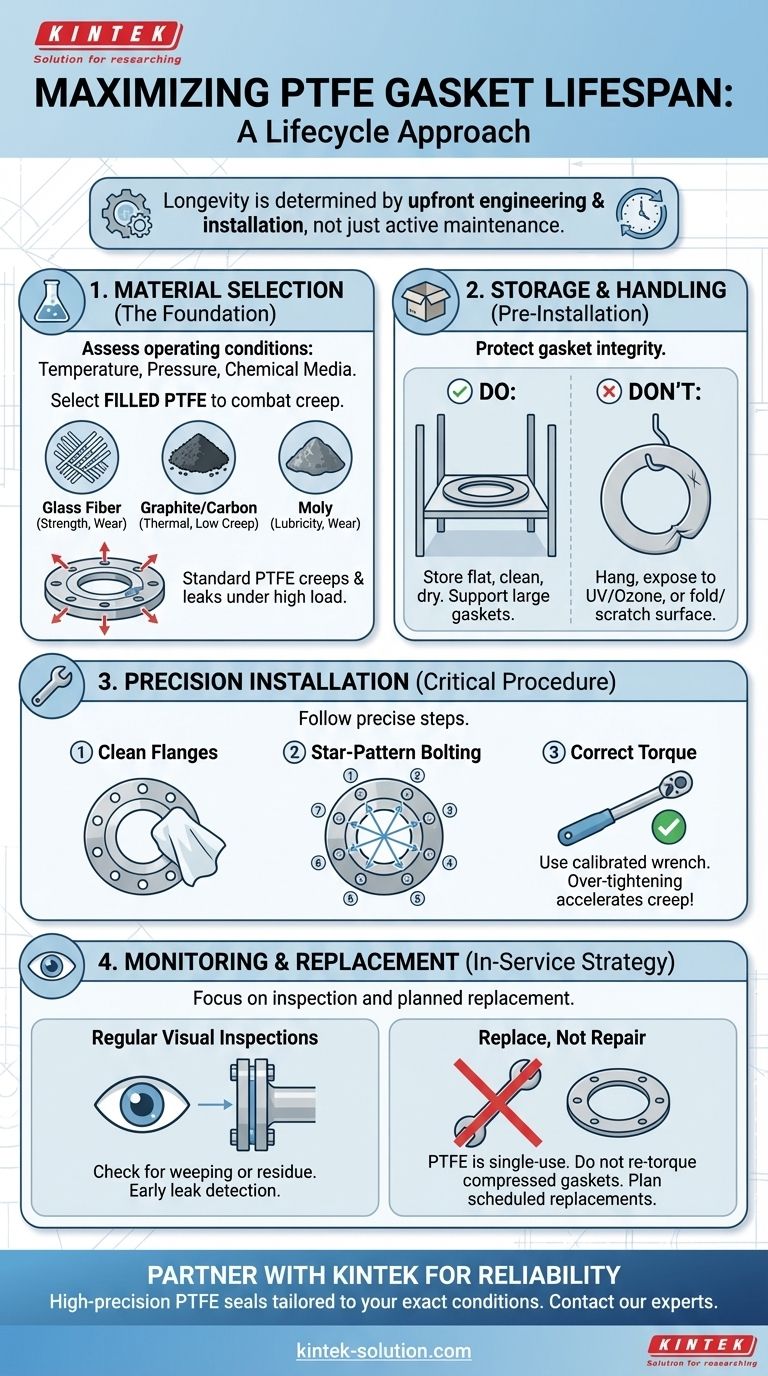

To extend the lifespan of a PTFE gasket, you must focus on the entire lifecycle, not just in-service maintenance. This involves selecting the correct material composition for your specific operating conditions, ensuring meticulous handling and storage, following precise installation procedures, and implementing a strategy of regular inspection rather than active repair.

The longevity of a PTFE gasket is determined less by active maintenance and more by the quality of your upfront engineering and installation. A gasket that is correctly specified, stored, and installed from the start will inherently have the longest possible service life.

The Foundation: Matching the Gasket to the Service

The single most important factor for gasket longevity is choosing the right material for the job. Standard PTFE is excellent for its chemical inertness, but its mechanical properties can be a significant limitation.

Assess Your Operating Conditions

Before selecting a gasket, you must have a clear understanding of the temperature, pressure, and chemical media it will be exposed to. PTFE is susceptible to a phenomenon called creep or cold flow, where the material deforms permanently under load, especially at elevated temperatures.

The Critical Role of PTFE Fillers

To combat creep and improve mechanical performance, manufacturers add fillers to the PTFE matrix. Each filler provides a different benefit:

- Glass Fiber: Improves compressive strength and wear resistance.

- Graphite & Carbon Fiber: Enhance strength, reduce creep, and improve thermal conductivity.

- Molybdenum Disulfide (Moly): Improves lubricity and wear resistance.

Selecting a filled PTFE is not an upgrade; it is a specific engineering choice required for services involving high pressure, temperature cycling, or significant vibration.

Why Standard PTFE Fails in the Wrong Application

Using a standard, unfilled PTFE gasket in a high-temperature or high-pressure application will almost certainly lead to premature failure. The material will creep out of the flange, causing a loss of bolt load and an eventual leak.

Pre-Installation: Protecting Gasket Integrity

A gasket can be compromised long before it ever sees service. Proper handling and storage are non-negotiable steps for ensuring a reliable seal.

Maintain a Controlled Storage Environment

Store gaskets flat in a clean, dry environment away from direct sunlight (UV radiation) and electric motors (ozone), which can degrade the material over time. Do not hang them, as this can cause stretching and distortion.

Handle with Care

Never carry a gasket by itself if it's large; support it with cardboard or a similar flat surface. A small nick, scratch, or fold on the gasket's sealing surface creates a potential leak path and renders the gasket unusable.

The Critical Installation Procedure

Even the perfect gasket will fail if installed incorrectly. Installation is a technical procedure that requires precision.

Ensure Flange Surfaces are Clean and Aligned

The surfaces of the flanges must be perfectly clean, dry, and free of any scoring or pitting from previous gaskets. Any misalignment between the flanges will cause uneven compression and create a leak.

Follow a Star-Pattern Bolting Sequence

Always tighten the bolts in a crisscross or "star" pattern. This ensures the clamping force is applied evenly across the entire gasket surface, preventing one area from being crushed while another is left too loose.

Use the Correct Torque Value

Every gasket type has a manufacturer-recommended torque value. Over-tightening is a primary cause of PTFE gasket failure. Excessive torque will crush the material and accelerate creep, squeezing the gasket out of the flange. Use a calibrated torque wrench for every installation.

In-Service Monitoring and Replacement Strategy

Once installed, a PTFE gasket cannot be "maintained" in the traditional sense. Your focus must shift to monitoring its performance and knowing when to replace it.

The Myth of "Maintaining" a PTFE Gasket

Unlike some other materials, you cannot simply "fix" a leaking PTFE gasket. Do not attempt to reuse a PTFE gasket after it has been compressed. It is a single-use consumable component. While some procedures allow for re-torquing after an initial settling period, this should only be done following specific manufacturer guidelines.

Regular Visual Inspections for Leaks

The primary "maintenance" task is to conduct regular, scheduled visual inspections of the flange joint. Look for any signs of weeping or product residue, which indicate the early stages of a leak.

Understanding Gasket Creep

Be aware that even with the correct gasket, some degree of creep will occur. This is the nature of PTFE. The goal of proper selection and installation is to manage this creep so that a sufficient seal is maintained throughout the gasket's expected service life.

Know When to Replace, Not Repair

When a leak is detected, the only reliable solution is to de-pressurize the system, remove the old gasket, inspect the flanges, and install a new gasket. Planning for scheduled replacements during planned downtime is the most effective strategy for critical systems.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities.

- If your primary focus is reliability in critical systems: Your efforts should be concentrated on meticulous material selection based on documented operating conditions and implementing a schedule of proactive replacement.

- If your primary focus is reducing maintenance costs: Prioritize training your team on precise installation techniques, especially proper bolting patterns and torque application, to prevent premature failures.

- If your primary focus is troubleshooting frequent failures: Start with a root cause analysis. Document the exact temperature, pressure, and media, and compare them against the specifications of the failing gasket to identify a material mismatch.

Ultimately, extending a gasket's life is an exercise in proactive engineering and precision, not reactive repairs.

Summary Table:

| Key Factor | Best Practice | Common Mistake to Avoid |

|---|---|---|

| Material Selection | Choose filled PTFE (e.g., glass, graphite) for high temp/pressure. | Using standard PTFE in demanding applications. |

| Installation | Follow star-pattern bolting with correct torque. | Over-tightening, which accelerates creep. |

| In-Service | Regular visual inspections for leaks; replace, don't repair. | Attempting to reuse a compressed gasket. |

| Storage & Handling | Store flat in a clean, dry environment; avoid nicks and folds. | Hanging gaskets or handling without support. |

Maximize the reliability and lifespan of your PTFE components with KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, choosing the right PTFE gasket is critical for system integrity. KINTEK specializes in manufacturing high-precision PTFE seals, liners, and labware tailored to your exact operating conditions—from custom prototypes to high-volume orders.

Don't let gasket failures disrupt your operations. Contact our experts today to discuss your specific requirements and ensure you have the right PTFE solution for superior performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE perform against stainless steel in terms of friction? Discover Unmatched Low-Friction Performance

- What are recommended tolerances for machining PTFE parts? Achieve Dimensional Stability & Cost-Effectiveness

- What industries benefit from TFE Encapsulated O-Rings and Gaskets? Ensure Reliability in Demanding Applications

- What are some examples of filled PTFE seals and their properties? Enhance Performance for Demanding Applications

- What makes PTFE spring-energized seals suitable for oil and gas applications? Unmatched Reliability in Extreme Conditions

- What are the manufacturing differences between PTFE and elastomer lip seals? A Guide to Performance and Cost

- What are the advantages of expanded PTFE sheet? Achieve Superior Sealing Reliability and Chemical Resistance

- What are some common applications of PTFE Expansion Bellows? Solve Corrosion, Temperature, and Vibration Challenges