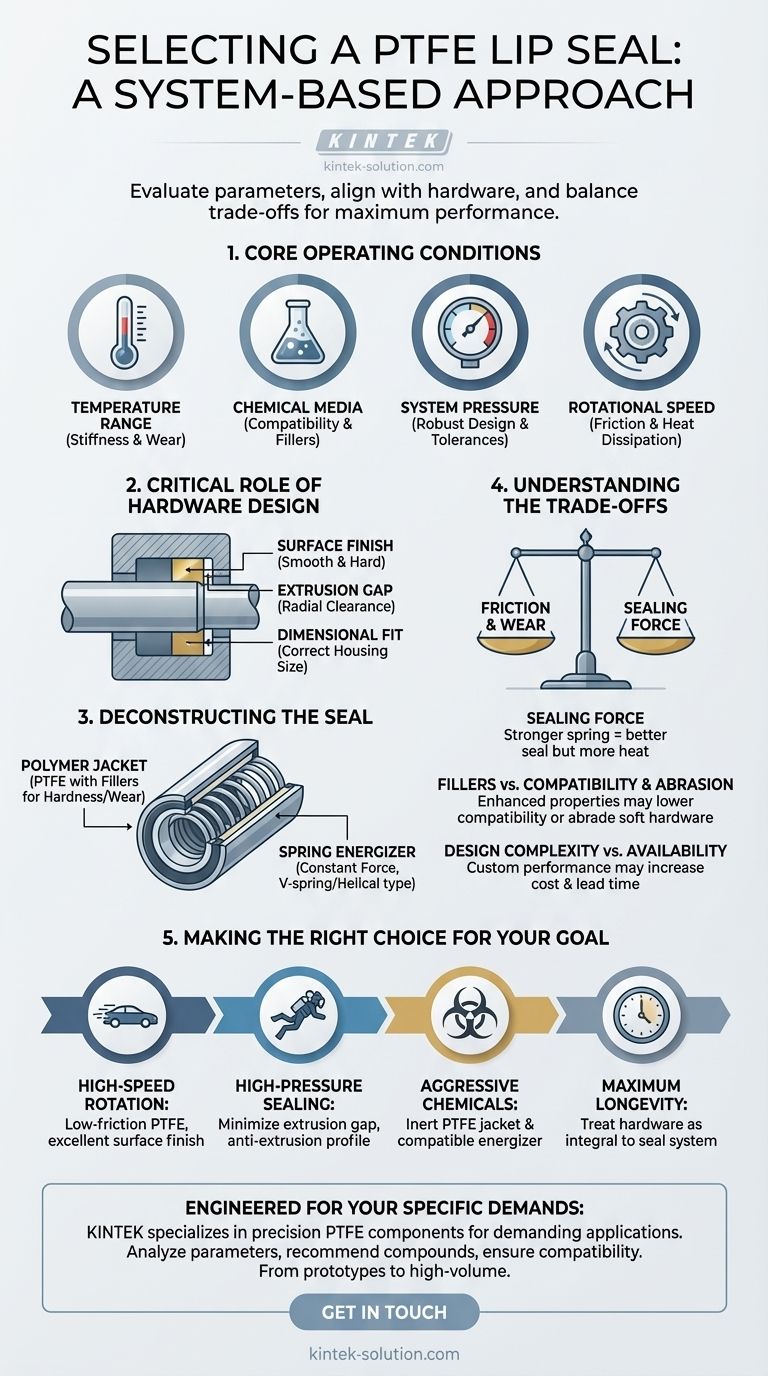

To select the correct PTFE lip seal, you must evaluate four primary operational parameters: temperature, chemical media, pressure, and rotational speed. These factors must then be matched with the seal's material composition, energizer type, and the physical constraints of your hardware.

Selecting a PTFE lip seal isn't about finding a single "best" part; it's about designing a sealing system. True reliability comes from aligning the seal's material and geometry with your specific hardware preparation and dynamic operating demands.

Understanding the Core Operating Conditions

The performance of any seal is dictated by its environment. PTFE seals are chosen for demanding applications, making a clear definition of these conditions the mandatory first step.

Temperature Range

The operational temperature window affects both the PTFE jacket and the internal spring energizer. PTFE offers a very broad range, but extreme cold can cause stiffening, while extreme heat can increase wear rates.

Chemical Media Exposure

PTFE is renowned for its near-universal chemical resistance. However, the specific fillers used to enhance its mechanical properties must also be compatible with the media being sealed.

System Pressure

The seal must be able to withstand the maximum system pressure without being physically forced into the hardware clearance gap. High pressure requires a robust seal design and tighter hardware tolerances.

Rotational Speed

High surface speeds generate significant frictional heat. The low-friction nature of PTFE makes it ideal for these applications, but proper design and lubrication are critical to dissipate this heat and prevent premature wear.

The Critical Role of Hardware Design

A high-performance seal will fail in a poorly prepared system. The hardware is not just a housing; it is an active component of the sealing system.

Surface Finish and Hardness

The dynamic surface, typically a shaft, must have a very smooth finish and sufficient hardness. A rough surface will act like an abrasive, rapidly destroying the seal lip, while a soft surface can be scored by the seal, creating a leak path.

Extrusion Gap (Radial Clearance)

This is the small gap between the rotating shaft and the stationary housing. If this gap is too large, high pressure can physically push the seal material into it, causing damage and failure. Precise control of this clearance is non-negotiable for high-pressure applications.

Dimensional Fit

The seal must fit correctly within its housing. An improper fit can lead to movement, leakage, or damage during installation, compromising the entire system from the start.

Deconstructing the Seal Itself

With the environment and hardware defined, you can properly specify the components of the seal.

The Polymer Jacket

The primary sealing element is the PTFE jacket. Pure PTFE is soft, so fillers like carbon, glass fiber, or graphite are added to increase hardness, improve wear resistance, and manage thermal expansion for specific applications.

The Spring Energizer

The spring provides the initial, constant energy needed to press the PTFE lip against the shaft, ensuring a tight seal even at low pressures. The type of spring (V-spring, helical, etc.) influences the sealing force and performance characteristics.

Understanding the Trade-offs

There is no universally perfect seal. Every design choice involves balancing competing factors.

Friction vs. Sealing Force

A stronger spring energizer creates a more aggressive seal, which is excellent for high-pressure or low-viscosity media. However, this increases friction, which in turn generates more heat and accelerates wear, particularly at high speeds.

Material Fillers and Properties

Adding fillers to the PTFE jacket enhances properties like hardness and wear resistance. The trade-off is that these fillers can sometimes reduce the overall chemical compatibility or increase abrasion on softer hardware.

Design Complexity vs. Availability

A highly customized seal might offer the best theoretical performance for your application. However, this can come at the cost of higher price, longer lead times, and difficult installation, which may make a standard, readily available option more practical.

Making the Right Choice for Your Goal

Your primary objective should guide your final selection criteria.

- If your primary focus is high-speed rotation: Prioritize a low-friction PTFE compound and ensure exceptional shaft surface finish to manage heat.

- If your primary focus is high-pressure sealing: Pay closest attention to minimizing the extrusion gap and select a seal design with a robust, anti-extrusion profile.

- If your primary focus is aggressive chemical compatibility: Select an unfilled PTFE jacket or one with a known inert filler, and verify the spring energizer material is also compatible.

- If your primary focus is maximum longevity: Treat the hardware as an integral part of the seal; investing in proper surface hardness and finish will yield the greatest returns on reliability.

A systematic approach that considers the entire sealing environment is the key to achieving maximum performance and reliability.

Summary Table:

| Key Selection Factor | Why It Matters |

|---|---|

| Temperature Range | Affects PTFE stiffness and energizer performance. |

| Chemical Media | Must be compatible with PTFE and its fillers. |

| System Pressure | Dictates seal design and hardware tolerances. |

| Rotational Speed | Generates frictional heat; requires low-friction design. |

| Hardware Design | Surface finish, hardness, and extrusion gap are critical. |

| Seal Composition | PTFE filler and energizer type must match the application. |

Need a PTFE Seal Engineered for Your Specific Demands?

Selecting the right PTFE lip seal is a complex balance of operating conditions, hardware, and material science. KINTEK specializes in designing and manufacturing precision PTFE components—including seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We partner with you to:

- Analyze your specific operating parameters (temperature, pressure, speed, media).

- Recommend or custom-fabricate the ideal PTFE compound and seal design.

- Ensure compatibility with your hardware for maximum system reliability.

From prototypes to high-volume orders, we deliver the precision and performance your application requires.

Contact us today to discuss your sealing challenge and receive expert support! Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications