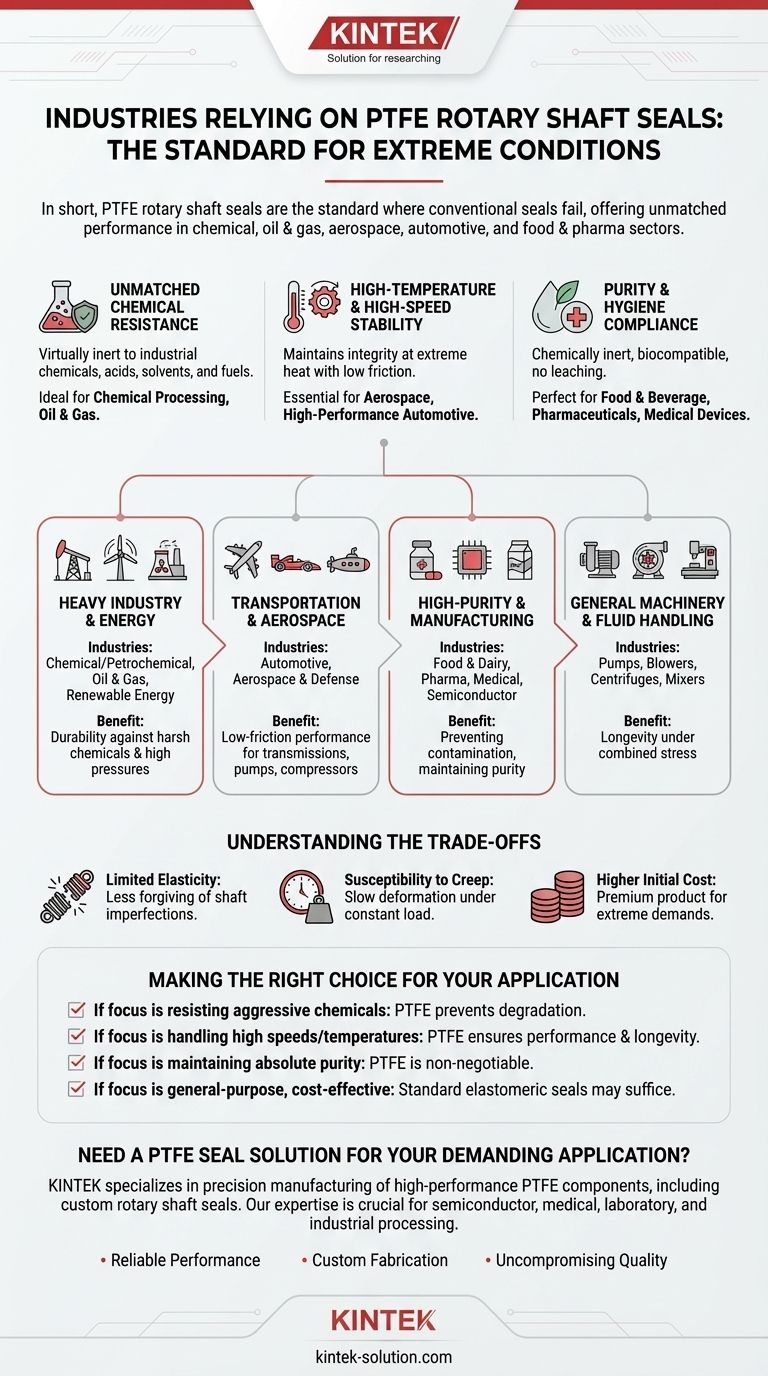

In short, PTFE rotary shaft seals are the standard in industries where conventional seals would fail. They are most commonly used in chemical processing, oil and gas, aerospace, automotive, and the food and pharmaceutical sectors due to their ability to withstand extreme operating conditions.

The core reason for their widespread adoption is simple: PTFE (polytetrafluoroethylene) provides a level of performance that traditional elastomeric seals cannot match. It solves critical challenges involving aggressive chemicals, high temperatures, high rotational speeds, and stringent purity requirements.

Why PTFE Seals Are Essential in Demanding Sectors

The choice to use a PTFE seal is driven by the material's unique properties. Standard rubber seals would quickly degrade or fail under the conditions where PTFE excels.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. This makes it the default choice for applications involving corrosive media.

It reliably seals against acids, solvents, and hydrocarbon-based fuels that would destroy other materials. This is critical in chemical processing and oil and gas industries, preventing leaks and reducing costly maintenance.

High-Temperature and High-Speed Stability

PTFE maintains its integrity at very high temperatures and has an exceptionally low coefficient of friction.

This combination is vital in aerospace components and high-performance automotive applications like engines and transmission systems. The low friction reduces heat generation and wear at high rotational speeds, extending the life of equipment like pumps, blowers, and screw compressors.

Purity and Hygiene Compliance

In industries where contamination is not an option, the purity of PTFE is a significant advantage.

Its chemical inertness and biocompatibility make it ideal for food and beverage processing, pharmaceutical production, and medical devices. The material does not leach chemicals or harbor bacteria, ensuring it meets strict hygiene standards.

A Cross-Industry Breakdown

While the properties of PTFE define its use, it's helpful to see how these benefits are applied across specific industrial categories.

Heavy Industry & Energy

This category includes chemical and petrochemical processing, oil and gas, and renewable energy. In these fields, seals are constantly exposed to harsh chemicals, high pressures, and extreme temperatures. PTFE's durability is essential for reliability and safety.

Transportation & Aerospace

From automotive engines to aerospace and defense systems, equipment operates at high speeds and temperatures. PTFE seals provide the low-friction, wear-resistant performance needed for components like transmissions, pumps, and compressors to function without failure.

High-Purity & Manufacturing

This group covers food and dairy, pharmaceutical, medical, and semiconductor manufacturing. The primary driver here is preventing contamination. PTFE's inertness ensures that the sealed media remains pure and unadulterated.

General Machinery & Fluid Handling

Many industrial machines rely on PTFE seals for longevity and efficiency. Applications include pumps, blowers, centrifuges, mixers, and machine tools where a combination of speed, temperature, and chemical exposure requires a high-performance sealing solution.

Understanding the Trade-offs

Despite its advantages, PTFE is not a universal solution. Understanding its limitations is key to using it correctly.

Limited Elasticity

Unlike rubber, PTFE is a relatively rigid material. It has very little "memory," meaning it does not spring back into shape as effectively as an elastomer. This can make it less forgiving of shaft imperfections or installation errors.

Susceptibility to Creep

Under a constant load, especially at elevated temperatures, PTFE can slowly deform over time—a phenomenon known as creep. This must be accounted for in the seal and hardware design to ensure a long-term, reliable seal.

Higher Initial Cost

PTFE rotary shaft seals are a premium product. They are generally more expensive than their standard elastomeric counterparts, making them an unnecessary expense for applications that do not involve extreme conditions.

Making the Right Choice for Your Application

Selecting the correct seal material comes down to balancing performance requirements with cost.

- If your primary focus is resisting aggressive chemicals: PTFE is the most reliable choice to prevent seal degradation and leakage.

- If your primary focus is handling high speeds or temperatures: PTFE's low-friction properties and thermal stability are critical for performance and longevity.

- If your primary focus is maintaining absolute purity: The inert and compliant nature of PTFE is non-negotiable for food, medical, or pharmaceutical applications.

- If your primary focus is a general-purpose, cost-effective solution: A standard elastomeric seal is likely more appropriate for applications without extreme operational demands.

Ultimately, PTFE is a specialized material engineered to solve the toughest sealing challenges.

Summary Table:

| Industry | Primary Benefit of PTFE Seal |

|---|---|

| Chemical & Oil & Gas | Unmatched resistance to corrosive acids and solvents |

| Aerospace & Automotive | Low friction & stability at high speeds and temperatures |

| Food, Pharma & Medical | Absolute purity, inertness, and compliance with hygiene standards |

| General Machinery | Longevity in pumps, mixers, and compressors under harsh conditions |

Need a PTFE Seal Solution for Your Demanding Application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom rotary shaft seals. Our expertise is crucial for industries like semiconductor, medical, laboratory, and industrial processing, where failure is not an option.

We provide:

- Reliable Performance: Seals engineered to withstand aggressive chemicals, extreme temperatures, and high speeds.

- Custom Fabrication: From initial prototypes to high-volume production runs, tailored to your exact specifications.

- Uncompromising Quality: Precision production ensures the purity and durability your application requires.

Let us help you solve your toughest sealing challenges. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What makes FEP and PTFE encapsulated O-rings suitable for chemical processing? Achieve Leak-Free Sealing in Corrosive Environments

- What is the temperature range that PTFE bushings can endure? Operate from -200°C to +260°C

- What are the advantages of PTFE Liner in terms of weight and noise reduction? Achieve Quieter, Lighter Systems

- Which chemicals react negatively with PTFE? Identify the Few Substances That Can Compromise Its Integrity

- What are the benefits of PTFE Mechanical Seals? Superior Chemical & Thermal Performance

- What are some examples of filled PTFE seals and their properties? Enhance Performance for Demanding Applications

- What materials can PTFE O-rings be produced with? From Virgin PTFE to Enhanced Compounds

- What purity standards do PTFE bellow seals meet? Ensure Compliance in Critical Applications