To be precise, PTFE O-rings are produced from pure (virgin) polytetrafluoroethylene or from PTFE that has been blended with filler materials to enhance specific properties. The most common fillers include glass, bronze, and graphite, each chosen to modify the O-ring's mechanical performance for more demanding applications.

The core principle is simple: while pure PTFE offers unparalleled chemical and temperature resistance, it is a relatively soft material. Adding specific fillers is a strategic engineering choice to improve its strength, wear resistance, and durability without significantly compromising its inherent benefits.

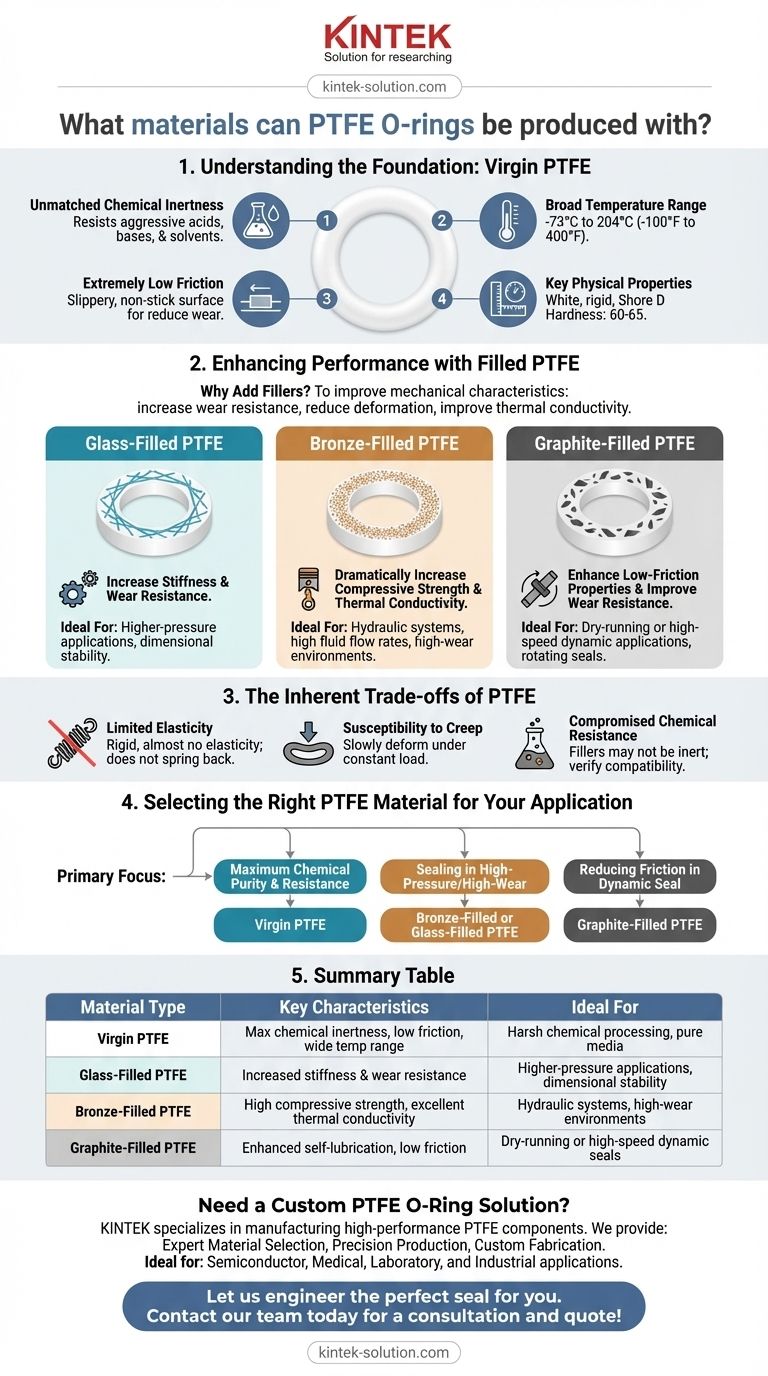

Understanding the Foundation: Virgin PTFE

Before exploring the variations, it's essential to understand the baseline properties of pure, or "virgin," PTFE. This material sets the standard for performance in several key areas.

Unmatched Chemical Inertness

Virgin PTFE is hydrophobic and famously resistant to nearly all industrial chemicals, including aggressive acids, bases, and solvents. This makes it a default choice for seals in harsh chemical processing environments.

Broad Temperature Range

PTFE maintains its integrity and performance across an exceptionally wide temperature spectrum, typically from -73°C to 204°C (-100°F to 400°F).

Extremely Low Friction

The material has one of the lowest coefficients of friction of any solid, resulting in a slippery, non-stick surface. This is highly beneficial for reducing wear and energy consumption in dynamic sealing applications like valve stems and pumps.

Key Physical Properties

Pure PTFE O-rings are typically white in color and are quite rigid compared to rubber O-rings. They have a hardness rating of 60 to 65 on the Shore D scale, indicating a hard plastic rather than a flexible elastomer.

Enhancing Performance with Filled PTFE

While virgin PTFE is exceptional, its mechanical properties can be a limitation. Fillers are added to the PTFE base to create composite materials that overcome these weaknesses.

Why Add Fillers?

The primary goal of adding fillers is to improve mechanical characteristics. This typically includes increasing wear resistance, reducing deformation under load (creep), and improving thermal conductivity.

Glass-Filled PTFE

Adding glass fibers is a common method to significantly increase stiffness and wear resistance. This compound is excellent for higher-pressure applications where dimensional stability under load is critical.

Bronze-Filled PTFE

Bronze powder is blended with PTFE to dramatically increase compressive strength and thermal conductivity. This makes it one of the most wear-resistant PTFE variants, ideal for hydraulic systems or applications with high fluid flow rates.

Graphite-Filled PTFE

Graphite is added to enhance the material's low-friction properties and improve wear resistance, especially in dry-running or high-speed dynamic applications. It creates a self-lubricating composite ideal for rotating seals.

The Inherent Trade-offs of PTFE

As a technical advisor, I must be clear that PTFE is not a universal solution. Understanding its limitations is critical for proper application.

Limited Elasticity

Unlike rubber elastomers, solid PTFE O-rings are rigid and have almost no elasticity. They do not spring back to their original shape after being compressed, which can make achieving a perfect seal more challenging, especially in low-pressure systems.

Susceptibility to Creep

Under a constant load (like the compression in a seal gland), PTFE can slowly deform over time, a phenomenon known as "creep." While fillers help mitigate this, it remains a consideration for long-term, high-load applications.

Compromised Chemical Resistance

While the PTFE base material remains inert, the fillers themselves may not be. For example, the bronze in a bronze-filled O-ring can be attacked by certain chemicals, compromising the seal's integrity. You must verify that both the PTFE and the filler are compatible with your media.

Selecting the Right PTFE Material for Your Application

Your choice should be dictated entirely by the specific demands of the operating environment.

- If your primary focus is maximum chemical purity and resistance: Virgin (unfilled) PTFE is the only choice.

- If your primary focus is sealing in high-pressure or high-wear applications: Bronze-filled or glass-filled PTFE provide the necessary strength and durability.

- If your primary focus is reducing friction in a dynamic seal: Graphite-filled PTFE offers enhanced self-lubricating properties.

Ultimately, choosing the correct PTFE composite is about balancing its exceptional chemical and thermal stability with the specific mechanical strength your application requires.

Summary Table:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| Virgin PTFE | Maximum chemical inertness, low friction, wide temp range (-73°C to 204°C) | Harsh chemical processing, pure media applications |

| Glass-Filled PTFE | Increased stiffness and wear resistance | Higher-pressure applications requiring dimensional stability |

| Bronze-Filled PTFE | High compressive strength, excellent thermal conductivity | Hydraulic systems, high-wear environments |

| Graphite-Filled PTFE | Enhanced self-lubrication, low friction | Dry-running or high-speed dynamic seals |

Need a Custom PTFE O-Ring Solution?

Selecting the right PTFE material is critical for your application's success. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom O-rings, seals, liners, and labware.

We provide:

- Expert Material Selection: Our engineers will help you choose between virgin, glass-filled, bronze-filled, or graphite-filled PTFE to perfectly match your requirements for chemical resistance, temperature, pressure, and wear.

- Precision Production: We prioritize precision manufacturing to ensure every O-ring meets exact specifications for a reliable seal.

- Custom Fabrication: From initial prototypes to high-volume production runs, we tailor our fabrication process to your needs.

Ideal for: Semiconductor, Medical, Laboratory, and Industrial applications.

Let us engineer the perfect seal for you. Contact our team today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability