The primary benefits of PTFE mechanical seals are their exceptional chemical inertness, extremely low friction coefficient, and wide operational temperature range. These properties make them the material of choice for demanding applications where conventional seals would quickly degrade or fail.

While many materials offer one key strength, PTFE's value lies in its unique combination of thermal stability, chemical resistance, and mechanical reliability. Understanding this synergy is the key to leveraging it effectively in challenging industrial environments.

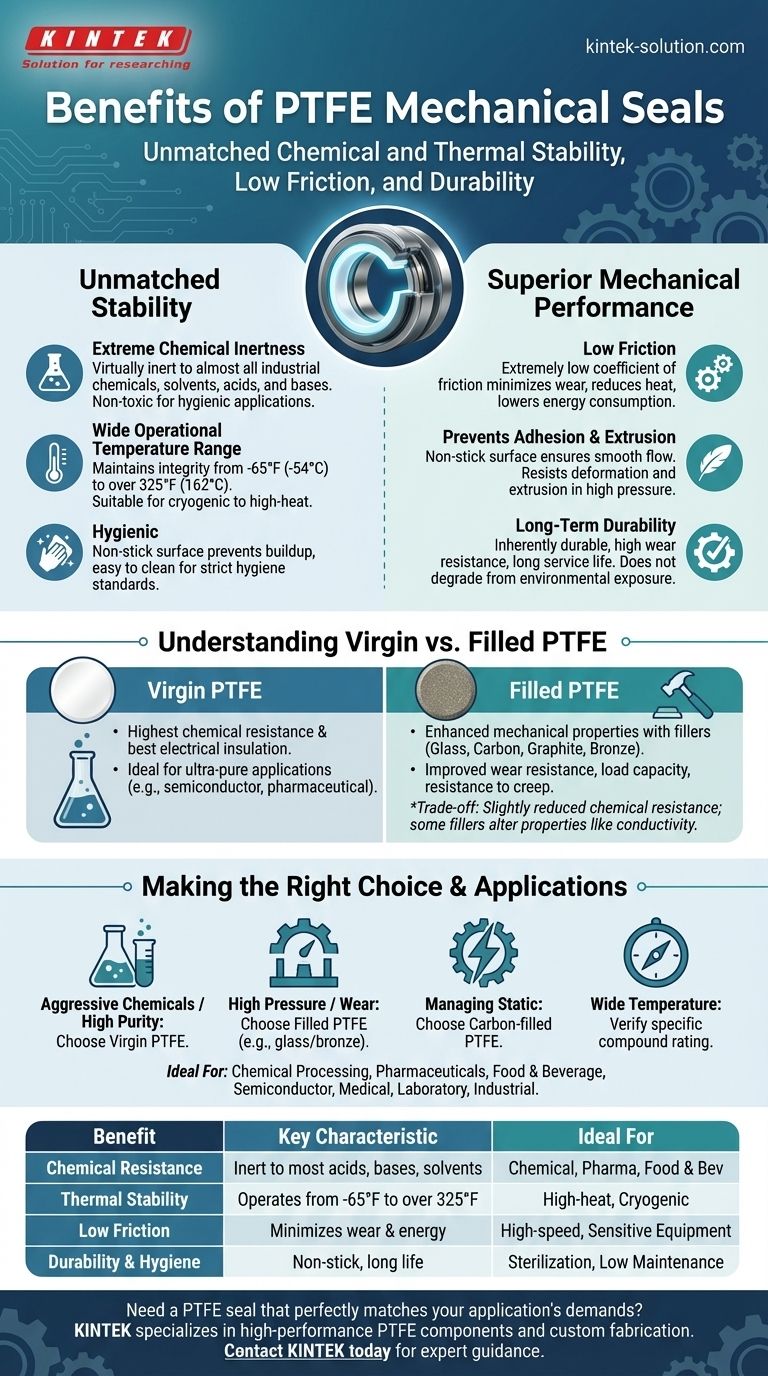

Unmatched Chemical and Thermal Stability

The core advantage of PTFE (Polytetrafluoroethylene) stems from its incredibly stable molecular structure. This stability translates directly into superior performance in extreme environments.

Extreme Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, solvents, acids, and bases. This makes it an essential material for seals in the chemical processing, pharmaceutical, and food and beverage industries.

Its non-toxic and physiologically inert nature also allows for safe use in applications requiring sterilization and disinfection.

Wide Operational Temperature Range

PTFE seals maintain their integrity and performance across a broad spectrum of temperatures. They can operate effectively in cryogenic conditions as low as -65°F (-54°C) and in high-heat applications up to 325°F (162°C) or more, depending on the specific grade.

Suitability for Hygienic Applications

The non-stick surface of PTFE prevents the buildup of deposits or scaling. This quality, combined with its inertness, makes it exceptionally easy to clean and ideal for industries with strict hygiene standards.

Superior Mechanical and Operational Performance

Beyond its resilience to harsh environments, PTFE provides distinct mechanical advantages that enhance efficiency and reduce maintenance.

The Advantage of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property minimizes wear on moving parts, reduces operational heat generation, and can lower the energy required to run the equipment.

Preventing Adhesion and Extrusion

Its non-stick surface ensures that media does not adhere to the seal, maintaining smooth fluid flow. In high-pressure applications, PTFE’s resistance to deformation and extrusion ensures the seal maintains its shape and effectiveness.

Long-Term Durability and Reliability

The material’s inherent durability, impact strength, and wear resistance contribute to a longer service life for the seal. This reduces downtime and the associated costs of maintenance and replacement. Furthermore, PTFE has a long shelf-life, as it does not degrade over time from environmental exposure.

Understanding the Trade-offs: Virgin vs. Filled PTFE

Not all PTFE is the same. The choice between pure "virgin" PTFE and a "filled" compound is critical and depends entirely on the application's specific demands.

The Purity of Virgin PTFE

Virgin PTFE offers the highest chemical resistance and best electrical insulation properties. It is the default choice for ultra-pure applications, such as in the semiconductor or pharmaceutical industries, where any contamination is unacceptable.

Enhancing Properties with Fillers

To improve mechanical characteristics, PTFE is often blended with fillers like glass, carbon, graphite, or bronze. These additives significantly enhance properties like wear resistance, load-bearing capacity, and resistance to "cold flow" or creep.

For example, a carbon-filled PTFE seal will exhibit much greater durability in a high-pressure, high-wear application than a virgin PTFE seal.

The Inherent Compromise of Fillers

Adding fillers almost always involves a trade-off. While they boost mechanical strength, they can slightly reduce the overall chemical resistance of the compound. Furthermore, some fillers can alter other properties; for instance, carbon is conductive and will lower the material's dielectric strength, making it unsuitable for high-voltage electrical applications.

Making the Right Choice for Your Application

Selecting the correct PTFE seal requires matching the material's properties to your primary operational goal.

- If your primary focus is aggressive chemicals or high purity: Choose virgin PTFE for its unmatched inertness and non-leaching characteristics.

- If your primary focus is high pressure and wear resistance: A filled PTFE, such as glass or bronze-filled, will provide the necessary mechanical strength and resistance to extrusion.

- If your primary focus is managing static electricity: A carbon-filled PTFE can provide the needed conductivity to dissipate static charge safely.

- If your primary focus is a wide temperature range: Most PTFE grades perform well, but always verify the specific compound's rating against your exact operational requirements.

Ultimately, choosing the right PTFE seal is about making an informed decision based on the specific demands of your system.

Summary Table:

| Benefit | Key Characteristic | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to most acids, bases, and solvents | Chemical processing, pharmaceuticals, food & beverage |

| Thermal Stability | Operates from -65°F to over 325°F | High-heat and cryogenic applications |

| Low Friction | Minimizes wear and energy consumption | High-speed or sensitive equipment |

| Durability & Hygiene | Non-stick, easy to clean, long service life | Applications requiring sterilization and low maintenance |

Need a PTFE seal that perfectly matches your application's demands?

KINTEK specializes in manufacturing high-performance PTFE components, including mechanical seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a seal with the right properties—whether you require the ultimate purity of virgin PTFE or the enhanced strength of a filled compound.

We provide custom fabrication from prototypes to high-volume orders, prioritizing precision to ensure reliability and longevity in your most challenging environments.

Contact KINTEK today to discuss your specific requirements and let our experts help you select or design the ideal PTFE seal for your system.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C