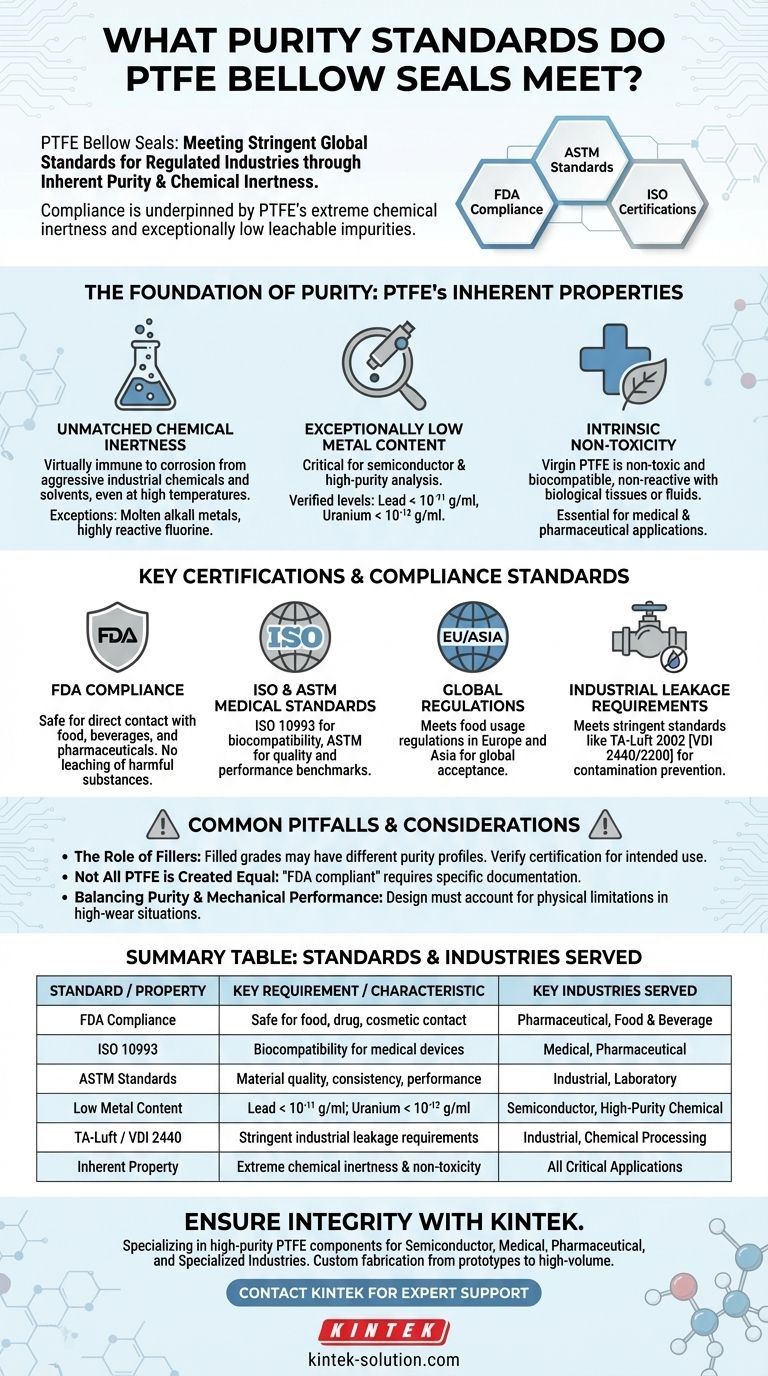

To be precise, PTFE bellow seals meet a comprehensive range of the most stringent purity and safety standards required by regulated industries. This includes compliance with FDA regulations for food and drug contact, ASTM material standards, and specific ISO certifications for medical applications, all of which are underpinned by the material's inherent chemical inertness and exceptionally low levels of leachable impurities.

The core reason PTFE bellow seals are trusted in high-purity applications is not just a list of certifications, but the fundamental nature of the material itself. Its extreme chemical inertness and non-toxic properties are the foundation upon which these critical industry standards are met.

The Foundation of Purity: PTFE's Inherent Properties

Understanding why PTFE bellow seals meet such high standards begins with the material's molecular structure. This structure is responsible for its unique and valuable characteristics.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually immune to corrosion or degradation from nearly all industrial chemicals and solvents.

Even under boiling conditions, it remains unaffected by aggressive reagents like concentrated sulfuric, nitric, or hydrochloric acid. The only known exceptions are molten alkali metals and some highly reactive fluorine compounds.

Exceptionally Low Metal Content

For applications like semiconductor manufacturing or high-purity chemical analysis, preventing trace metal contamination is paramount.

PTFE bellow seals are manufactured to maintain extremely low metallic content, with verified levels of lead below 10⁻¹¹ g/ml and uranium below 10⁻¹² g/ml.

Intrinsic Non-Toxicity

Virgin PTFE is non-toxic and biocompatible, meaning it does not react with biological tissues or fluids. This property is fundamental to its use in medical devices and pharmaceutical production.

Key Certifications and Compliance Standards

Industry standards provide third-party verification of a material's suitability for a specific use. PTFE bellow seals consistently meet the following critical benchmarks.

FDA Compliance

PTFE is a material that conforms to the Federal Food, Drug, and Cosmetic Act. This FDA compliance certifies it as safe for direct contact with food, beverages, and pharmaceutical products, ensuring it will not leach harmful substances.

ISO and ASTM Medical Standards

For medical applications, "Medical Grade" PTFE liners and components comply with rigorous ISO standards, such as ISO 10993 for biocompatibility.

Compliance with ASTM standards further ensures the material's quality, consistency, and performance characteristics meet established safety and engineering benchmarks.

European and Asian Regulations

In addition to US standards, compliant PTFE also meets food usage regulations in Europe and Asia, making it a globally accepted material for sensitive applications.

Industrial Leakage Requirements

Beyond purity, physical sealing performance is critical. PTFE meets stringent industrial leakage standards like TA-Luft 2002 [VDI 2440/2200], confirming its ability to effectively prevent contamination from entering a system.

Common Pitfalls and Considerations

While PTFE offers exceptional purity, it's crucial to understand the context to ensure you select the correct material for your specific application.

The Role of Fillers

Some PTFE seals include fillers (like glass, carbon, or graphite) to enhance mechanical properties such as strength or creep resistance.

While these filled grades still meet many standards, they may have a different purity profile than virgin PTFE. Always verify that the specific filled compound is certified for your intended use.

Not All PTFE is Created Equal

The terms "FDA compliant" or "Medical Grade" refer to specific formulations and manufacturing processes. You must obtain documentation from the supplier for the exact seal you are purchasing to guarantee compliance.

Balancing Purity and Mechanical Performance

The primary strength of PTFE is its chemical and thermal stability, not its mechanical resilience. In high-pressure or high-wear situations, you must ensure the seal's design accounts for PTFE's physical limitations to prevent mechanical failure.

Making the Right Choice for Your Goal

To ensure you are leveraging the correct properties of PTFE, focus on the specific demands of your industry.

- If your primary focus is pharmaceutical or medical manufacturing: Demand seals with explicit Medical Grade and ISO 10993 certifications to guarantee biocompatibility.

- If your primary focus is food and beverage processing: Verify direct FDA compliance for food contact and confirm it meets any relevant regional regulations.

- If your primary focus is semiconductor or high-purity chemical analysis: Require documentation specifying extremely low trace metal content, particularly for elements like lead and uranium.

Ultimately, you must always verify that the specific PTFE bellow seal you choose carries the precise certifications required for your application's safety and integrity.

Summary Table:

| Standard / Property | Key Requirement / Characteristic | Key Industries Served |

|---|---|---|

| FDA Compliance | Safe for direct food, drug, and cosmetic contact. | Pharmaceutical, Food & Beverage |

| ISO 10993 | Biocompatibility for medical devices. | Medical, Pharmaceutical |

| ASTM Standards | Material quality, consistency, and performance. | Industrial, Laboratory |

| Low Metal Content | Lead < 10⁻¹¹ g/ml; Uranium < 10⁻¹² g/ml. | Semiconductor, High-Purity Chemical |

| TA-Luft / VDI 2440 | Meets stringent industrial leakage requirements. | Industrial, Chemical Processing |

| Inherent Property | Extreme chemical inertness and non-toxicity. | All Critical Applications |

Ensure your application's integrity with certified PTFE components from KINTEK.

Do you require bellow seals, liners, or custom labware that meet stringent FDA, ISO, or semiconductor purity standards? KINTEK specializes in the precision manufacturing of high-purity PTFE components for the semiconductor, medical, pharmaceutical, and specialized industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your specific compliance and performance needs are met.

Contact KINTEK today to discuss your project requirements and receive expert support.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What materials can Expanded PTFE replace in specific applications? A Guide to Simplifying Your Sealing Inventory

- What are important installation tips for PTFE butterfly valves? Ensure a Leak-Free, Long-Lasting Seal

- What are the key benefits of PTFE O-rings? Superior Sealing for Extreme Conditions

- What are the key performance parameters of PTFE gland packings? Maximize Seal Performance and Reliability

- What are the main differences between RPTFE and standard PTFE for valve seats? Choose the Right Material for Your System

- What mechanical properties make PTFE bellows durable for critical applications? Ensure Long-Term Reliability in Demanding Environments

- What temperature range can expanded PTFE gaskets withstand? From Cryogenic -200°C to High-Temp 260°C

- What factors should be considered when choosing PTFE bars for chemical applications? Select the Right Grade for Your Process