The key benefits of PTFE O-rings are their unparalleled chemical resistance, extremely wide temperature tolerance, and very low coefficient of friction. This unique combination makes them the preferred choice for demanding static sealing applications where conventional rubber-based O-rings would degrade and fail due to aggressive media or extreme heat and cold.

The central takeaway is this: PTFE O-rings are not a direct replacement for standard rubber O-rings. They are a specialized sealing solution for static applications, chosen when the operational environment is too chemically aggressive or thermally extreme for any elastomer to survive.

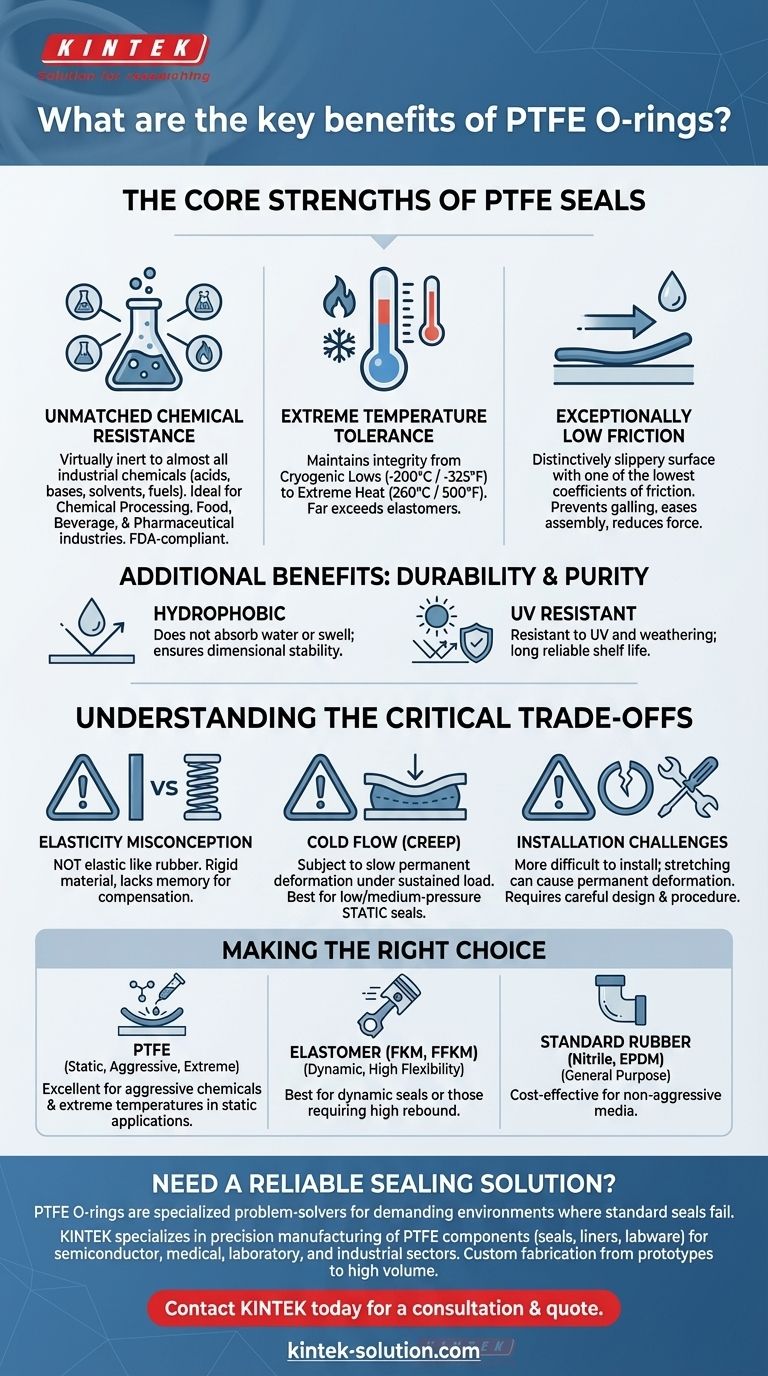

The Core Strengths of PTFE Seals

Polytetrafluoroethylene (PTFE) is a fluoropolymer, a type of plastic, not an elastomer like rubber. Its benefits stem directly from its unique molecular structure.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. This includes aggressive acids, bases, solvents, and fuels that would quickly destroy materials like Nitrile or EPDM.

This universal resistance makes it highly suitable for applications in the chemical processing, food, beverage, and pharmaceutical industries, where purity and non-reactivity are critical. It is also FDA-compliant.

Extreme Temperature Tolerance

PTFE O-rings maintain their integrity across a vast temperature range, typically from cryogenic lows of -325°F (-200°C) up to 500°F (260°C).

This capability far exceeds that of most elastomers, making PTFE essential for equipment operating in high-temperature processing or cryogenic systems.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a distinctively slippery surface.

This property is valuable during assembly, as it prevents galling and damage to mating surfaces. It also reduces the force required to connect components.

Durability and Purity

PTFE is hydrophobic, meaning it does not absorb water or swell. This ensures dimensional stability over time.

It is also highly resistant to UV radiation and weathering, giving it an extremely long and reliable shelf life without degradation.

Understanding the Critical Trade-offs

Choosing PTFE requires a clear understanding of its limitations. Its primary strength—being a stable plastic—is also the source of its primary weaknesses compared to rubber.

The Elasticity Misconception

Unlike elastomers, PTFE is not elastic. It is a rigid material that does not readily compress and rebound like rubber.

This lack of "memory" means it cannot effectively compensate for surface imperfections or thermal expansion and contraction in the same way a flexible O-ring can.

The Risk of Cold Flow (Creep)

Under sustained compressive load, PTFE is subject to cold flow, or creep. This means it will slowly and permanently deform over time.

This tendency can lead to a loss of sealing force, particularly in high-pressure applications or those with frequent pressure or temperature cycles. This is why it is best suited for low to medium-pressure static seals.

Installation Challenges

The rigidity of a solid PTFE O-ring makes it more difficult to install than a flexible rubber O-ring. Stretching it over a component can cause permanent deformation or damage.

For this reason, proper gland design and careful installation procedures are absolutely critical to achieving a reliable seal.

Making the Right Choice for Your Application

Selecting the correct O-ring material is a crucial engineering decision. PTFE should be viewed as a problem-solver for specific, demanding scenarios rather than a general-purpose option.

- If your primary focus is sealing against aggressive chemicals or extreme temperatures in a static application: PTFE is an excellent, and often the only viable, choice.

- If your primary focus is a dynamic seal or one requiring high flexibility and rebound: You should specify an elastomeric O-ring like FKM (Viton®) or FFKM (Kalrez®).

- If your primary focus is a cost-effective, general-purpose seal for non-aggressive media: A standard material like Nitrile (Buna-N) or EPDM is a more appropriate and economical solution.

Ultimately, understanding both the exceptional strengths and the inherent limitations of PTFE is key to engineering a reliable and long-lasting seal.

Summary Table:

| Key Benefit | Description | Key Consideration |

|---|---|---|

| Chemical Resistance | Inert to virtually all acids, bases, and solvents. | Ideal for chemical processing, pharma, and food industries. |

| Temperature Range | Performs from -200°C (-325°F) to 260°C (500°F). | Far exceeds the capabilities of standard elastomers. |

| Low Friction | Exceptionally slippery surface for easy assembly. | Reduces galling and damage to mating components. |

| Primary Limitation | Lacks elasticity and is subject to cold flow (creep). | Best for static, low-to-medium pressure seals only. |

Need a Reliable Sealing Solution for Demanding Environments?

PTFE O-rings are a specialized solution for applications where aggressive chemicals, extreme temperatures, or requirements for purity would cause standard rubber seals to fail. Selecting the right material and design is critical for performance and longevity.

KINTEK specializes in the precision manufacturing of PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom fabrication from prototypes to high-volume orders.

Let us help you engineer the perfect seal for your application. Our expertise ensures you get a component that delivers maximum reliability and performance.

Contact KINTEK today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs